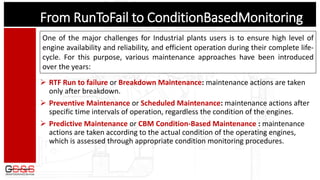

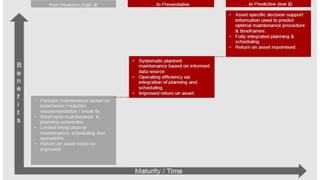

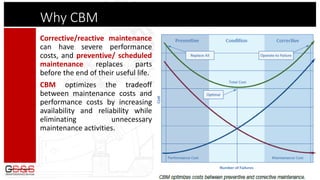

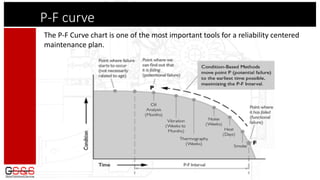

The document discusses the evolution of maintenance strategies from reactive to predictive maintenance, highlighting the benefits of condition-based maintenance (CBM) for optimizing engine reliability and performance. CBM leverages real-time data monitoring and analysis to schedule maintenance based on actual asset conditions, reducing costs and unscheduled downtime. It underscores the importance of data acquisition, processing, and decision-making in establishing effective CBM practices, while also noting the challenges associated with implementation.