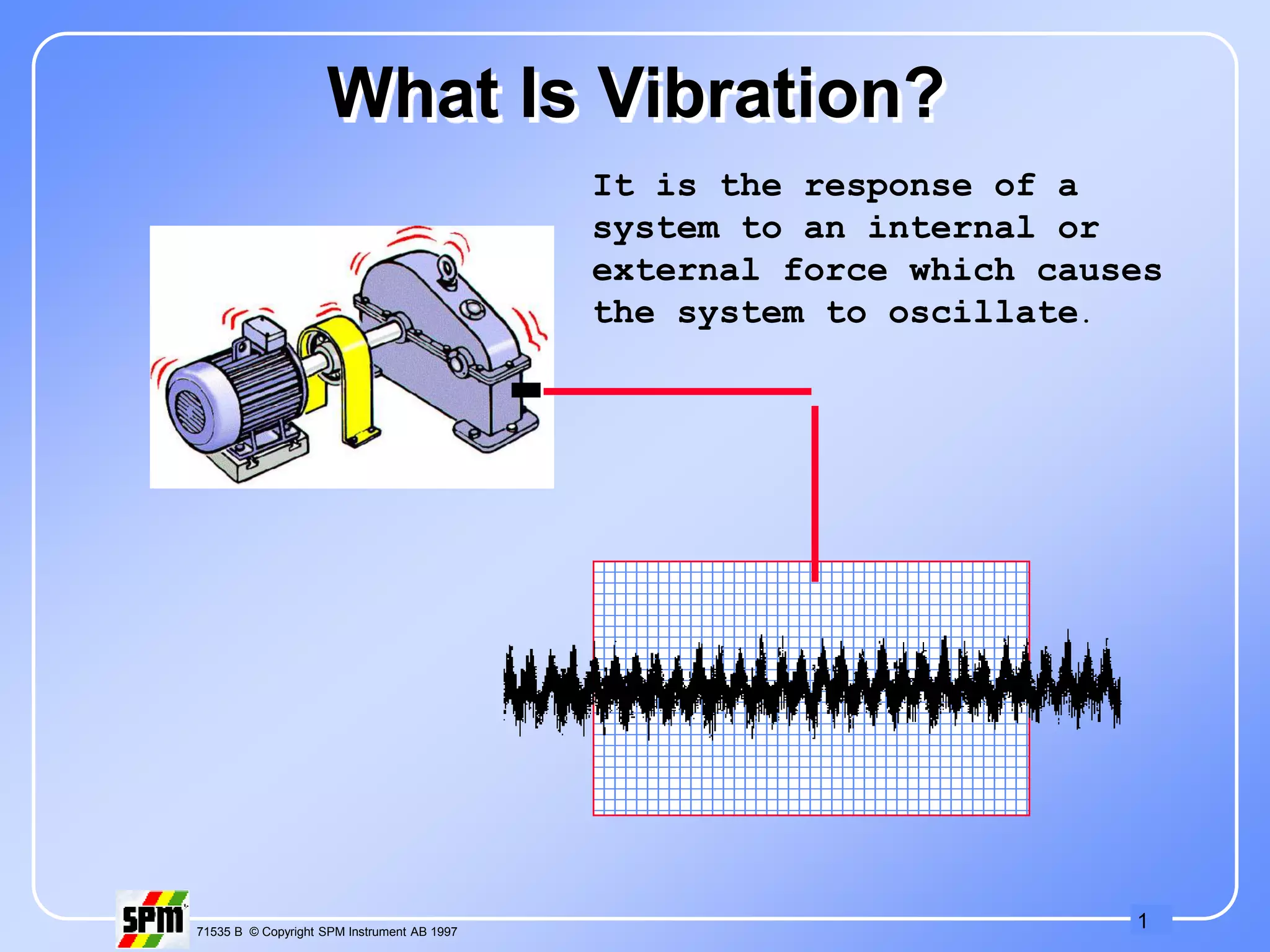

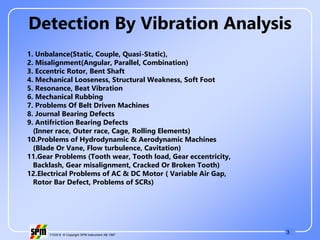

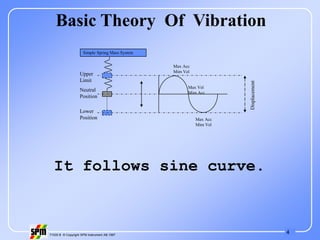

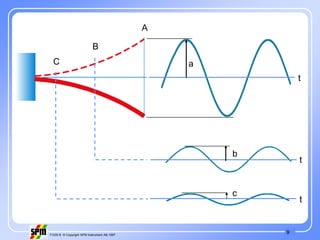

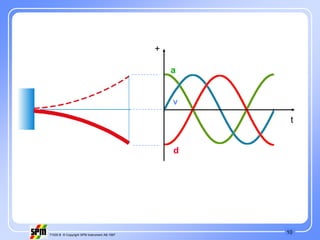

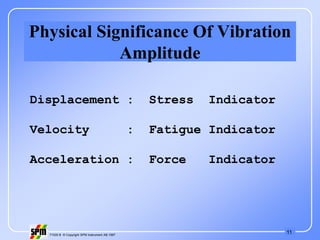

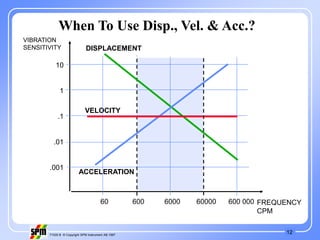

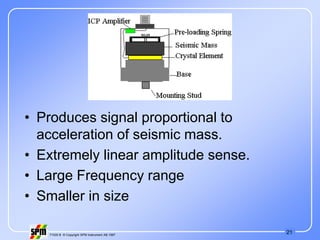

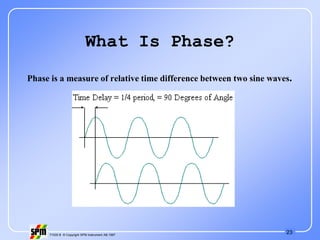

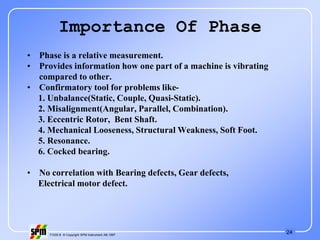

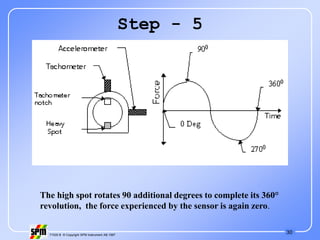

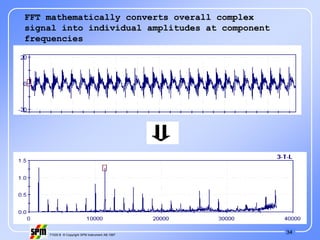

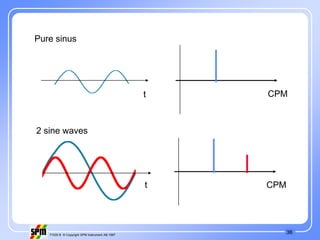

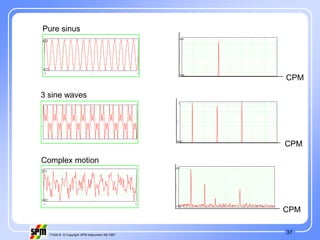

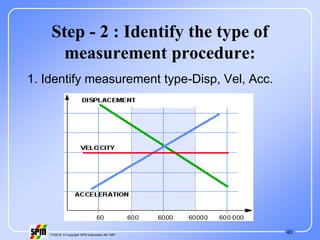

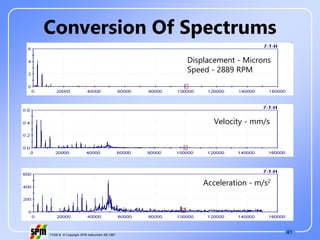

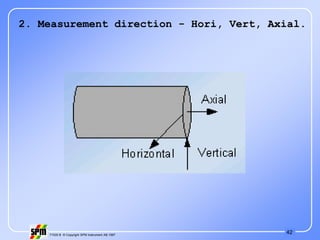

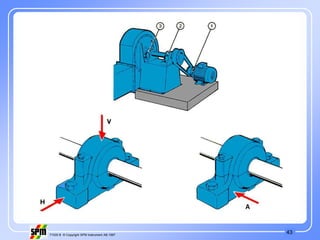

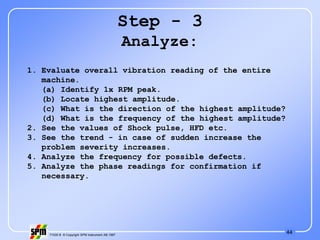

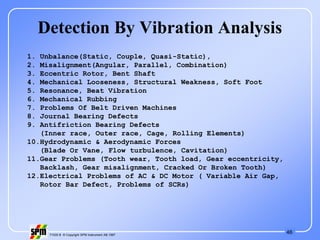

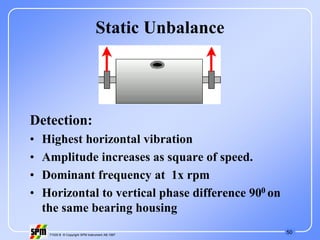

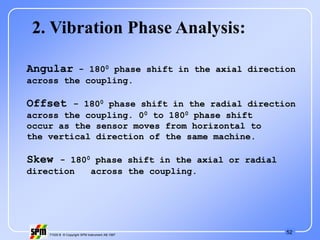

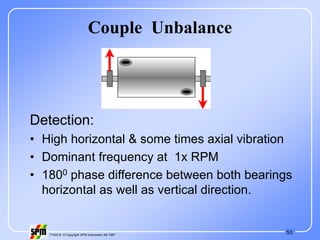

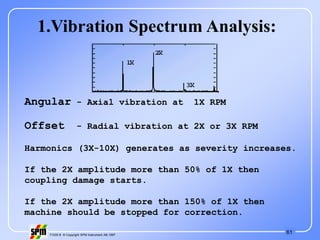

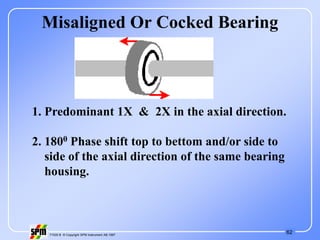

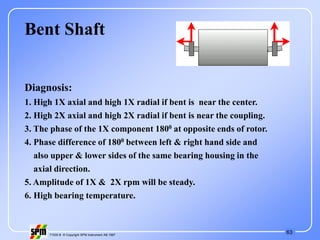

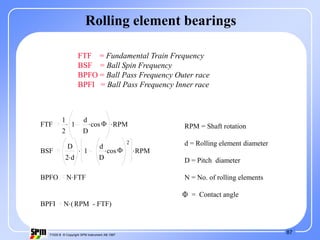

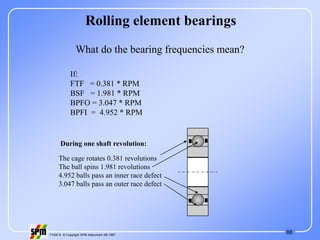

Vibration analysis is a non-destructive technique used to detect machine problems by measuring vibration. It can detect issues like unbalance, misalignment, bent shafts, bearing defects, and more. Vibration is measured by devices that detect displacement, velocity, or acceleration. Fast Fourier Transform (FFT) analysis breaks down vibration data into individual frequency components to help identify the source of issues. Manual vibration analysis involves examining FFT spectra and phase readings to diagnose specific faults based on indicators like dominant frequencies and amplitude readings.