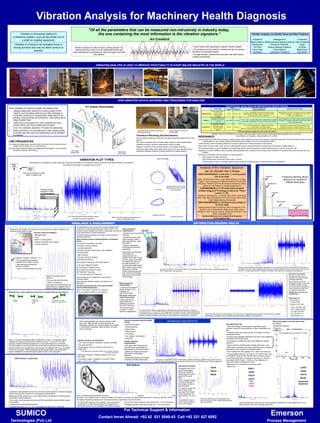

Vibration analysis can be used to diagnose common machinery faults through analysis of vibration signatures. Different types of faults generate unique vibration patterns with frequencies related to machine geometry and operating speed. Vibration data is captured using transducers like accelerometers mounted in appropriate locations. Signal processing techniques like the fast Fourier transform are used to analyze the frequency spectrum of the vibration and identify potential faults based on characteristic peaks. Common faults include imbalance, misalignment, bearing defects, resonance, and looseness.