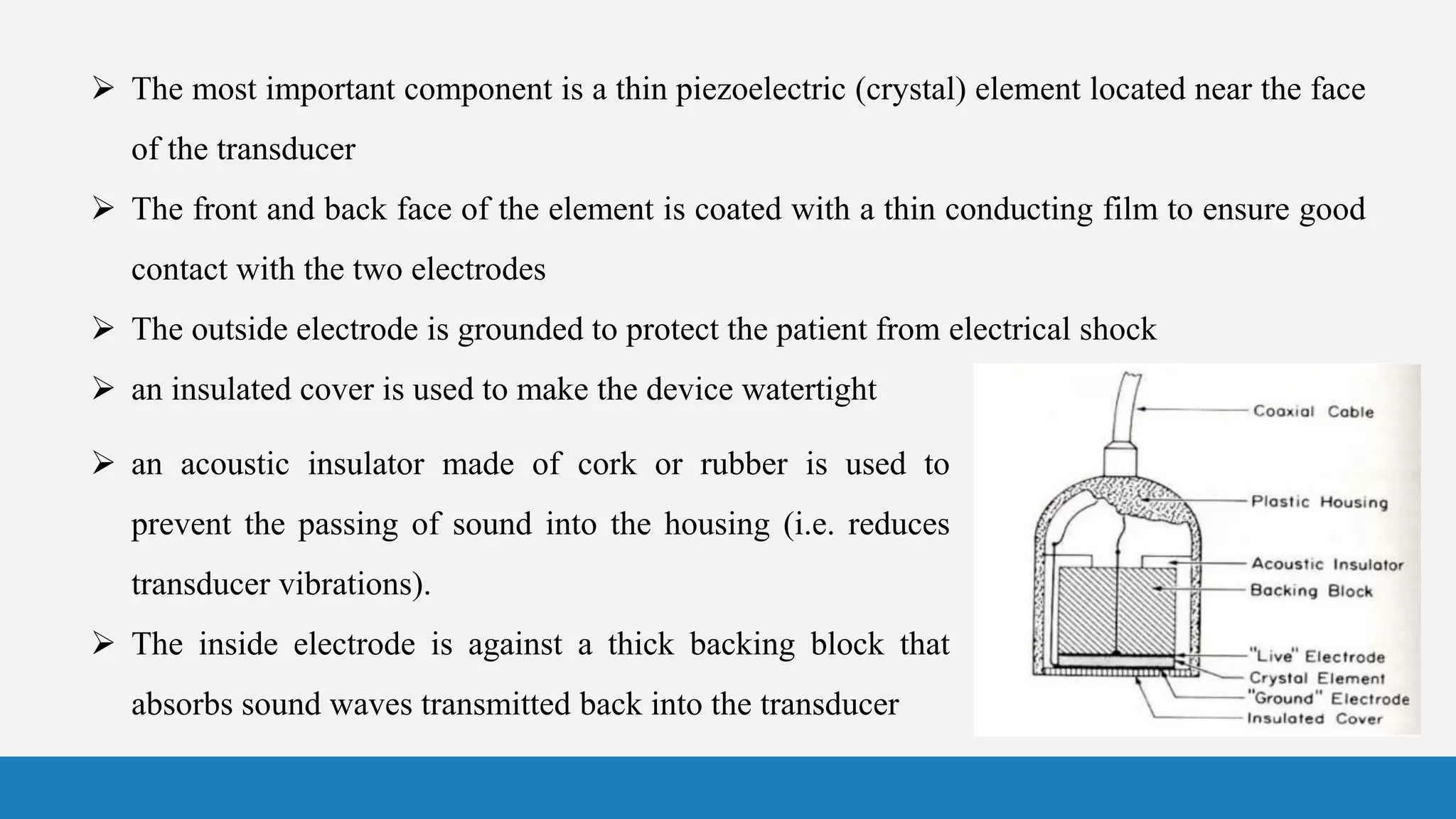

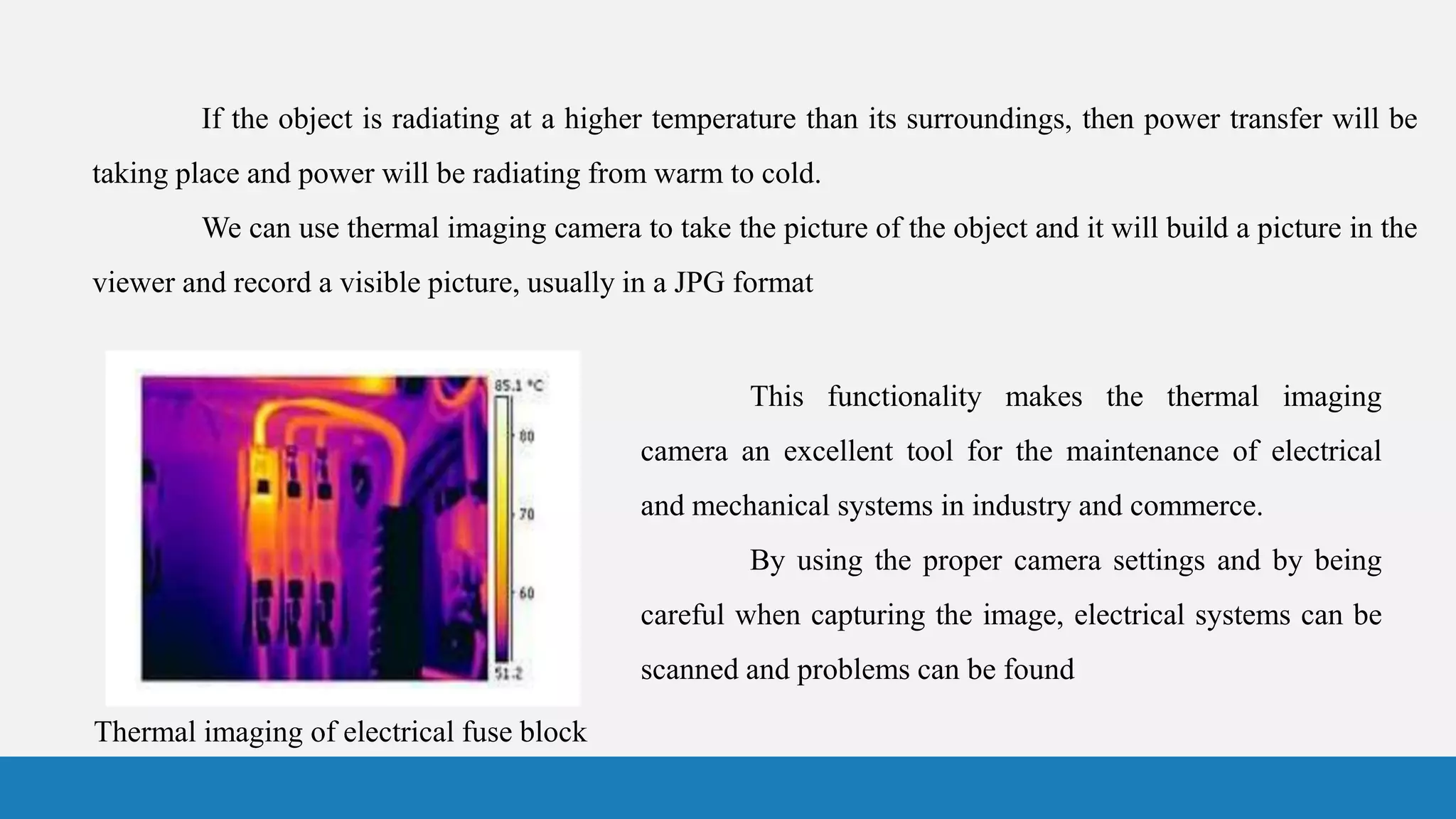

Condition monitoring (CM) is a process that tracks machinery parameters like vibration and temperature, crucial for predictive maintenance. Techniques include vibration analysis, oil analysis, ultrasound analysis, and thermal analysis, each providing real-time insights into machine conditions to preemptively address faults. While CM offers significant advantages in maintenance efficiency and product quality, it may also strain resources and management efforts.