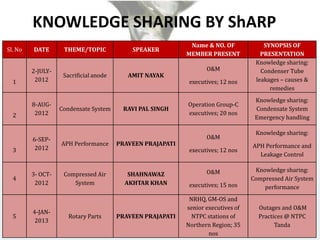

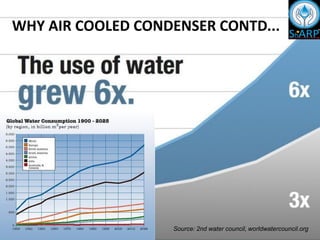

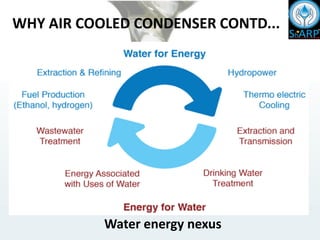

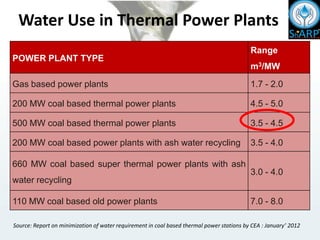

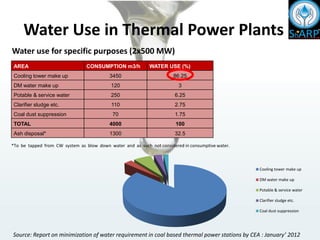

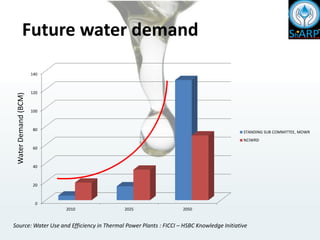

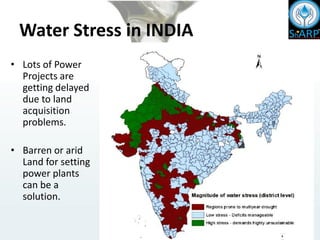

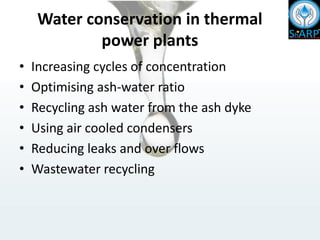

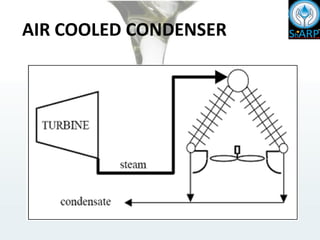

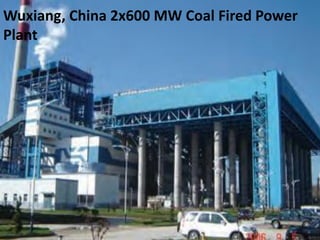

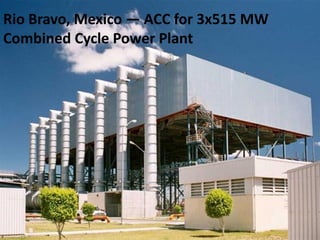

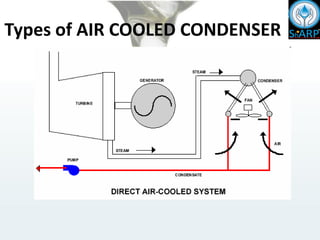

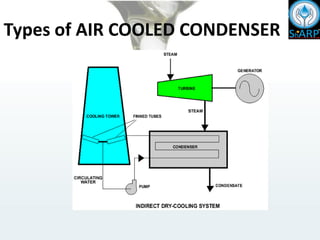

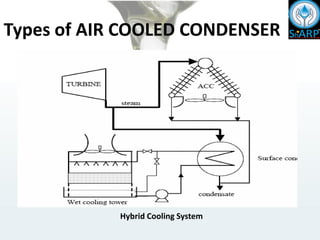

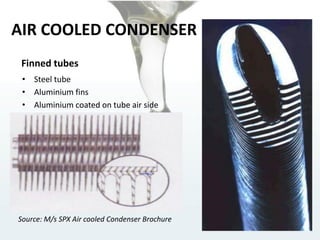

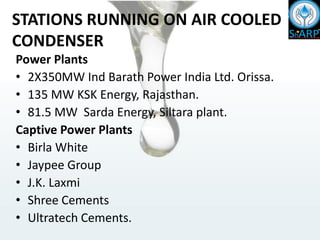

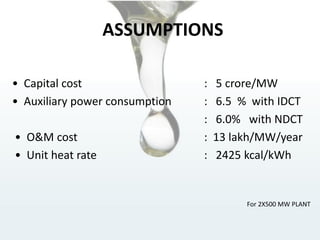

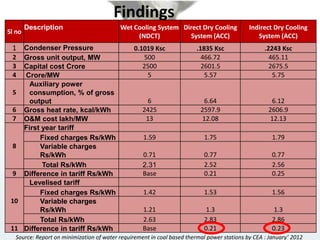

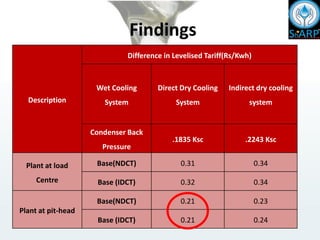

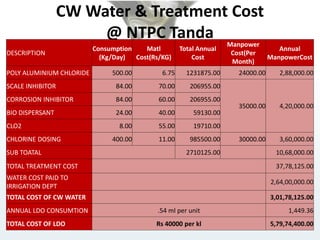

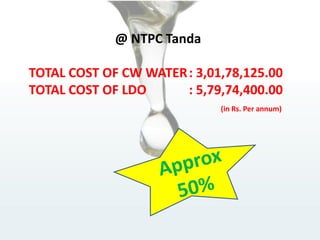

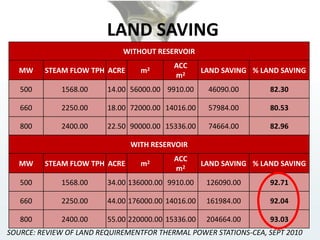

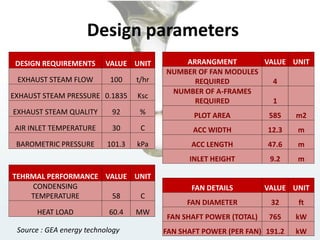

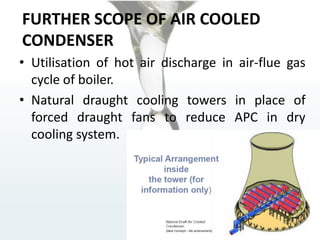

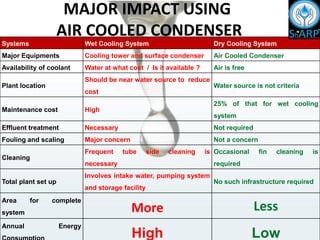

The document details a series of presentations by a team at NTPC Tanda focusing on technical aspects of thermal power plants, particularly addressing water use and conservation through air-cooled condenser systems. It highlights the increasing demand for water in power generation, potential water scarcity issues, and the economic implications of dry cooling technologies. The findings advocate for air-cooled systems to minimize water dependency and address future regulatory constraints on water use in energy production.