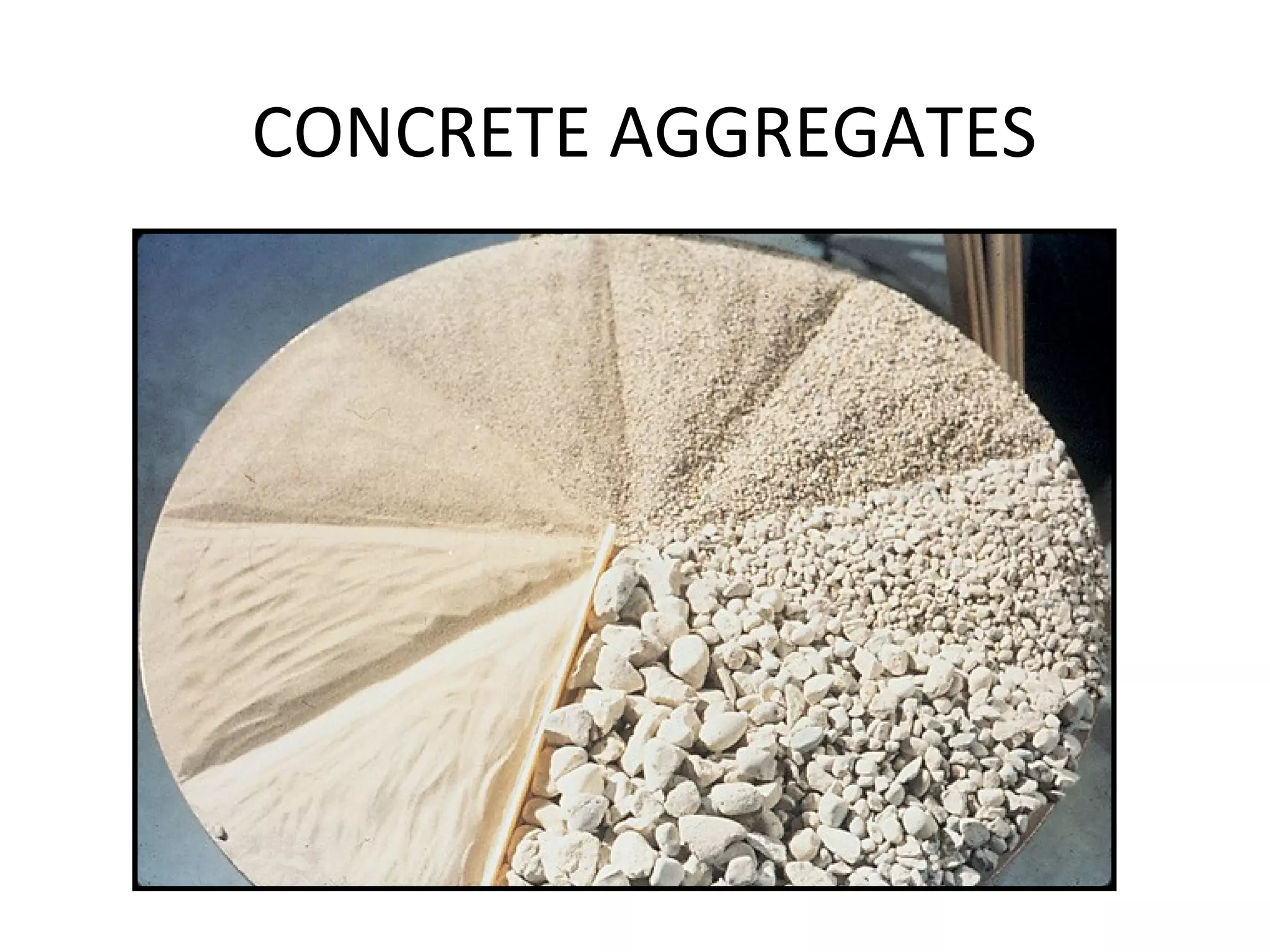

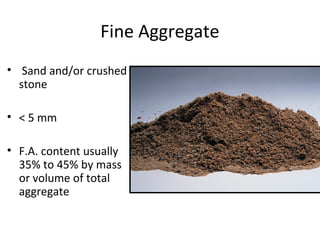

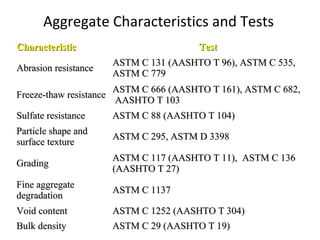

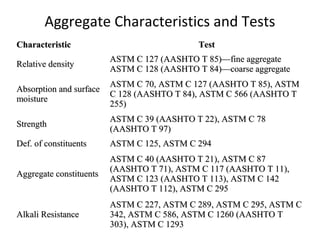

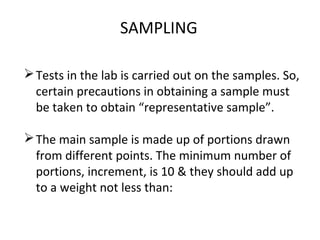

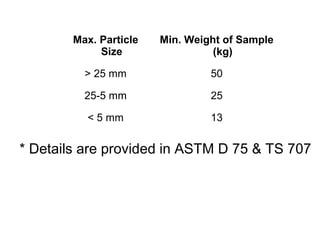

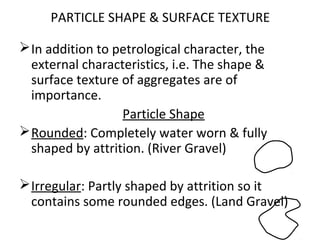

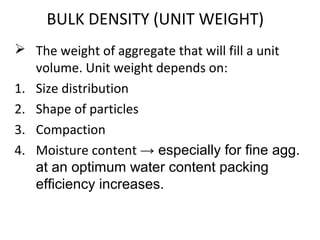

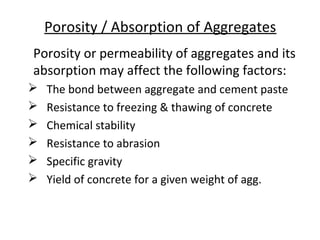

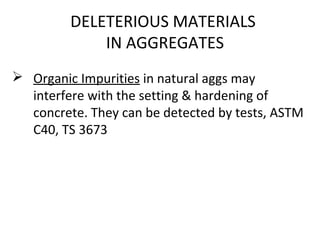

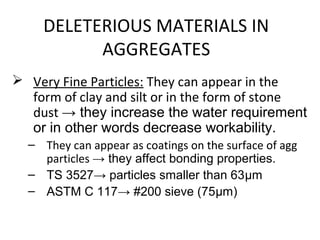

Concrete aggregates make up 70-75% of concrete by volume and influence its properties like strength, durability, and economy. Aggregates are classified based on source, petrological characteristics, unit weight, and size. Their shape, surface texture, grading, and mineral composition affect workability and bonding. Aggregates provide mass to resist loads, act as a filler, and reduce volume changes during curing. Proper sampling and testing ensures aggregates meet specifications for use in concrete.