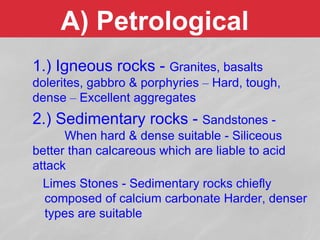

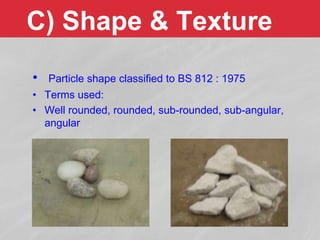

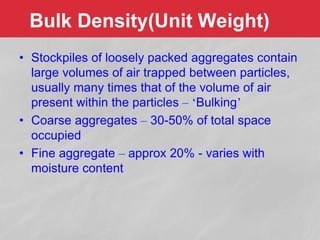

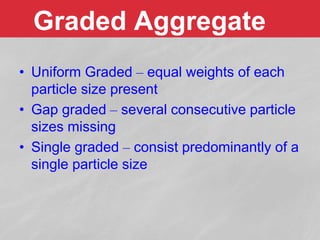

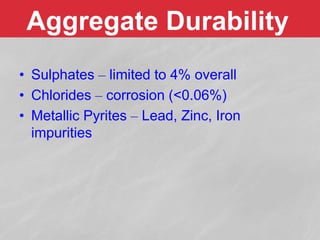

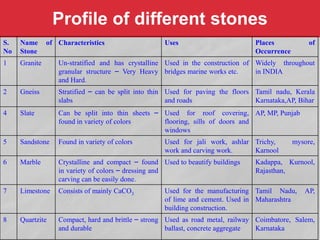

The document outlines the essential properties and classifications of concrete aggregates, which make up 70-75% of concrete's total volume. It categorizes aggregates into coarse (>4.75mm) and fine (<4.75mm) based on size, detailing their characteristics, grading, and suitability for various construction applications. Additionally, it discusses the effects of chemical and physical properties on aggregate performance and durability in concrete.