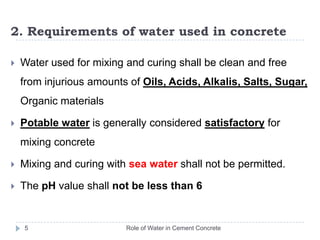

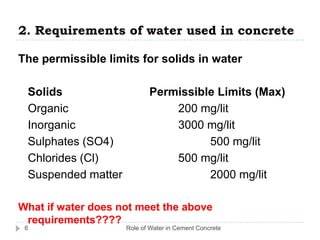

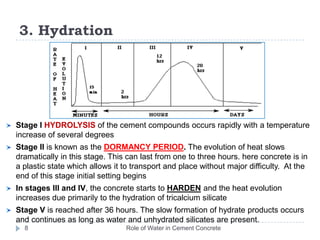

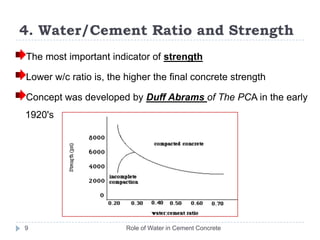

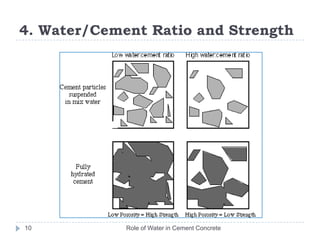

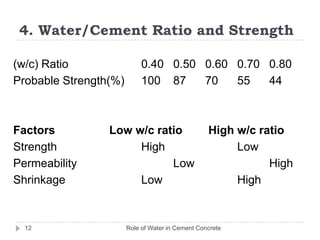

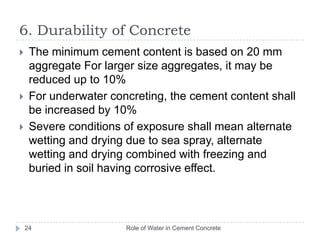

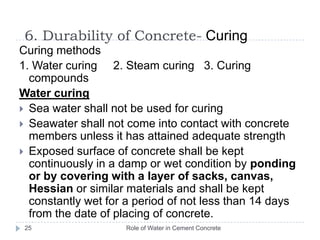

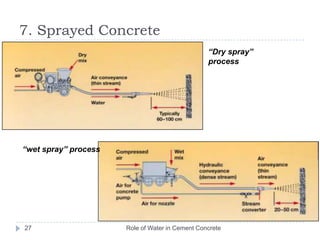

Water plays a key role in cement concrete as it acts as a reactant in the chemical process of hydration that provides concrete its strength over time. The water-cement ratio is an important factor, with lower ratios producing higher strength concrete. Water used for mixing must meet requirements for quality and impurities. Admixtures can be used to improve workability or reduce the water content. Proper curing is also important for achieving design strength and durability of the concrete. Sprayed concrete has advantages over poured concrete such as lower permeability and faster strength gain.