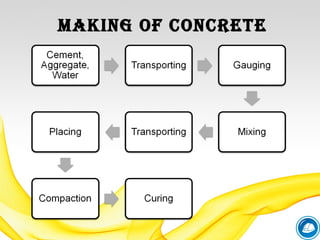

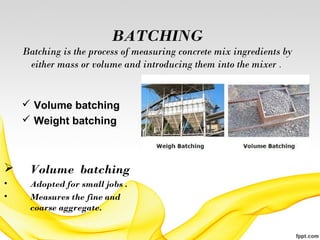

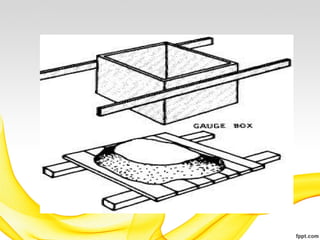

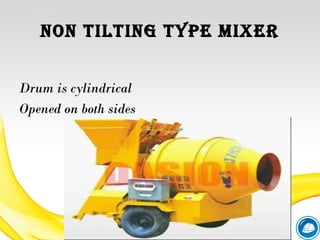

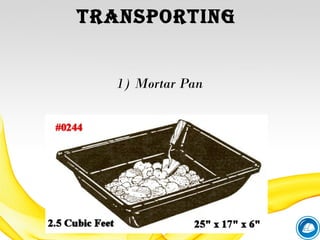

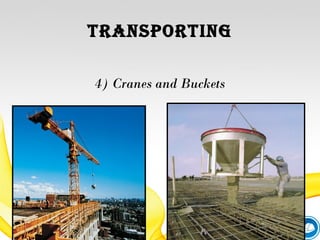

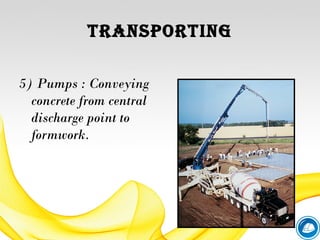

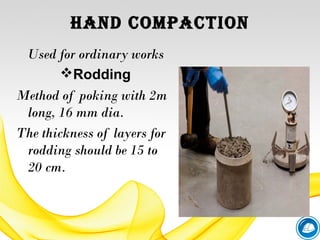

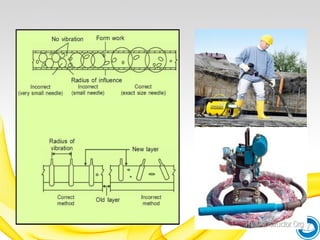

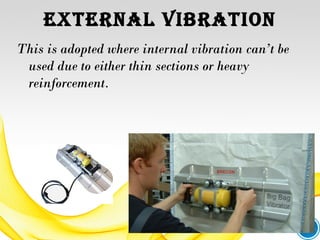

This document provides an overview of concrete technology. It discusses the composition of concrete including cement, water, and aggregates. It also describes the process of making concrete including batching, mixing, transporting, placing, compacting, curing, and finishing. Batching can be done by volume or weight, with weight batching being more precise. Concrete is mixed either by hand or using stationary mixers and is transported using various methods before being placed, compacted to remove air, and cured to allow further hydration. Finishing operations are the last steps to achieve the required surface.