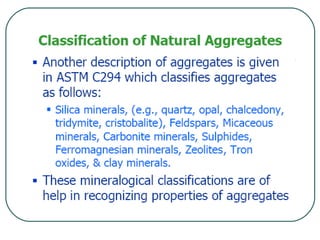

Aggregates are a combination of different sized stones used in construction. They are classified based on size, source, and density. Fine aggregates are less than 5mm while coarse aggregates are greater than 5mm. Natural aggregates come from sources like rivers while manufactured aggregates are crushed. Normal weight aggregates have densities from 1520-1680kg/m3 while lightweight aggregates are less than 1120kg/m3. Tests are conducted to determine properties like strength, hardness, durability and water absorption. Sieve analysis tests the grading and ensures a range of aggregate sizes are present.