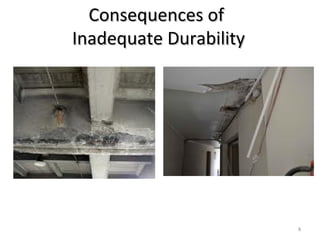

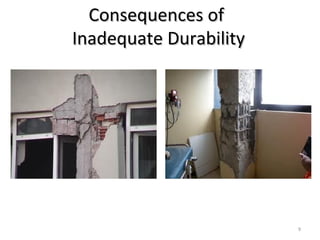

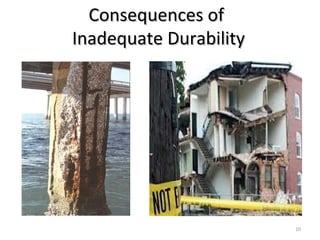

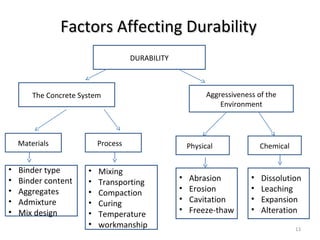

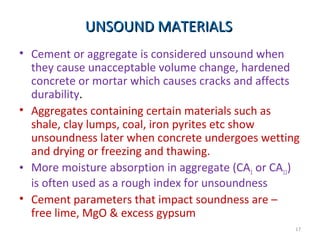

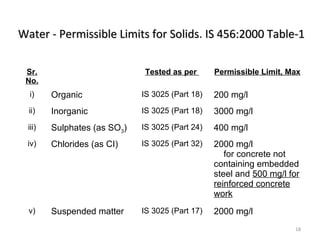

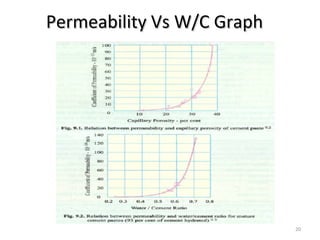

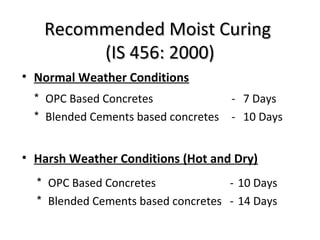

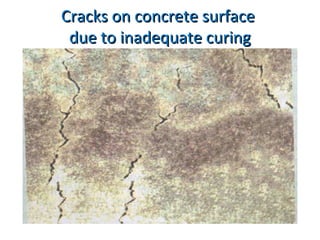

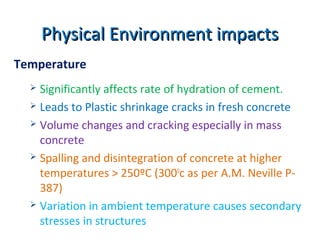

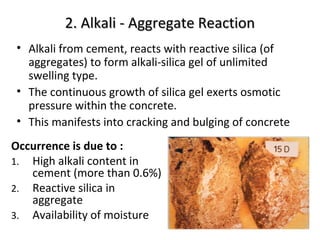

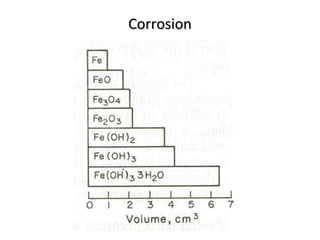

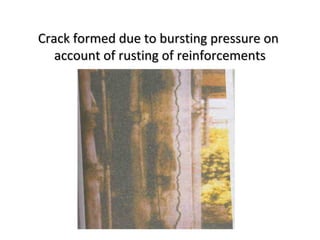

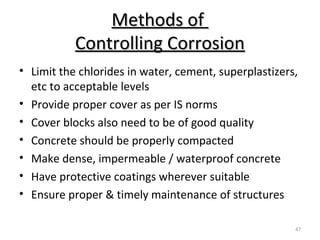

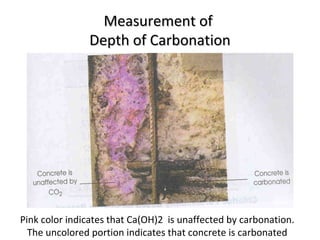

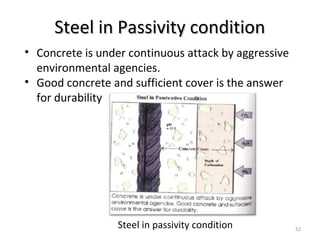

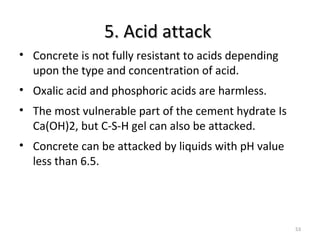

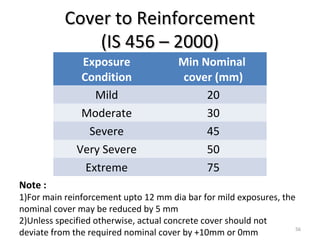

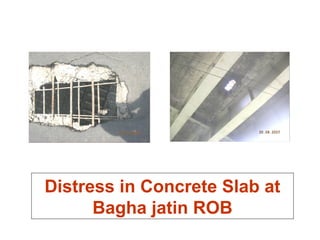

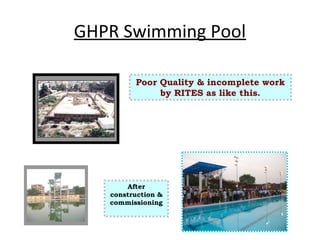

This document discusses quality control and durability factors in concrete. It defines quality as conformance to requirements and durability as a concrete's ability to resist deterioration when exposed to the environment. Several factors influence concrete durability, including the materials used, water-cement ratio, compaction, curing and the physical and chemical conditions of the service environment. Common durability issues include corrosion, cracking from sulfate attack or alkali-silica reaction, and carbonation reducing alkalinity. Proper quality control of materials and construction processes is needed to produce durable concrete.