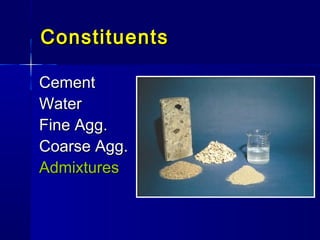

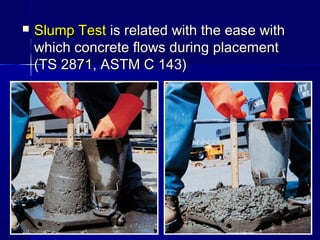

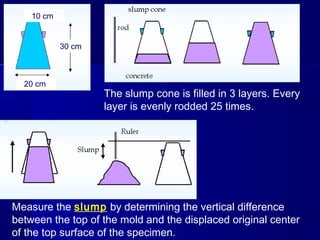

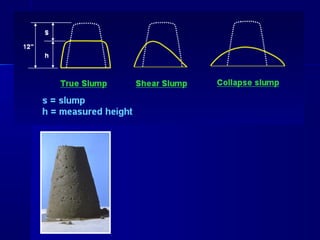

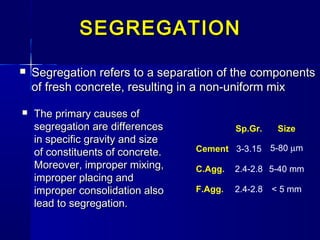

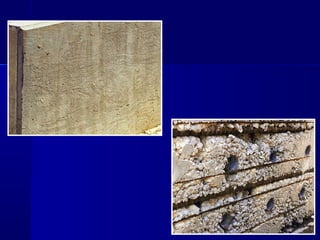

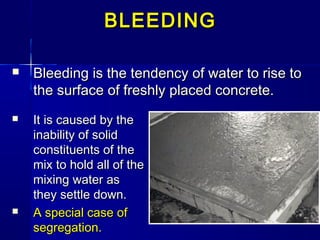

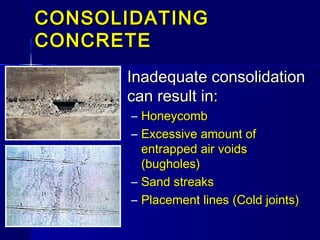

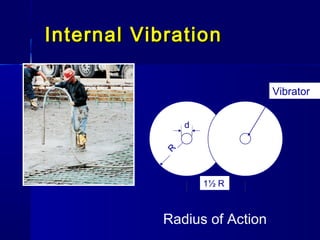

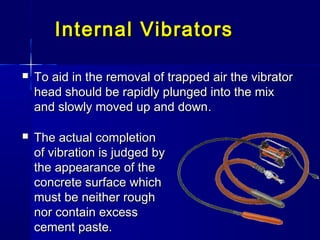

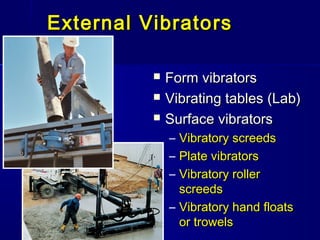

This document discusses concrete, one of the most commonly used building materials. Concrete is a composite material made from readily available constituents like aggregates, sand, cement, and water. It is versatile and can be easily mixed to meet different needs. The document covers the properties of fresh concrete, including workability, consistency, segregation, bleeding, and setting time. It discusses factors that affect these properties and different tests used to measure consistency, such as slump tests. The document also covers mixing, placing, and consolidating concrete.