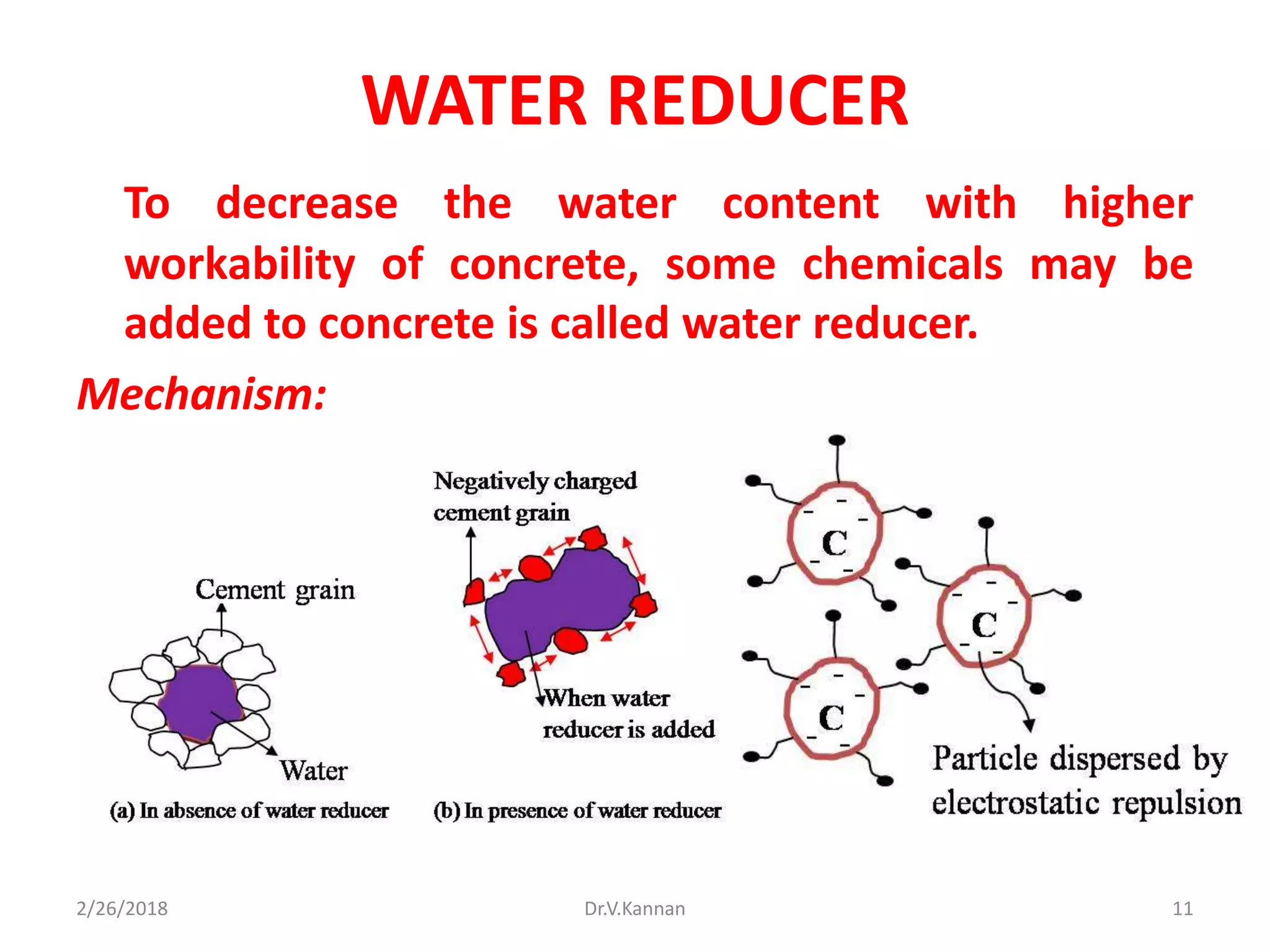

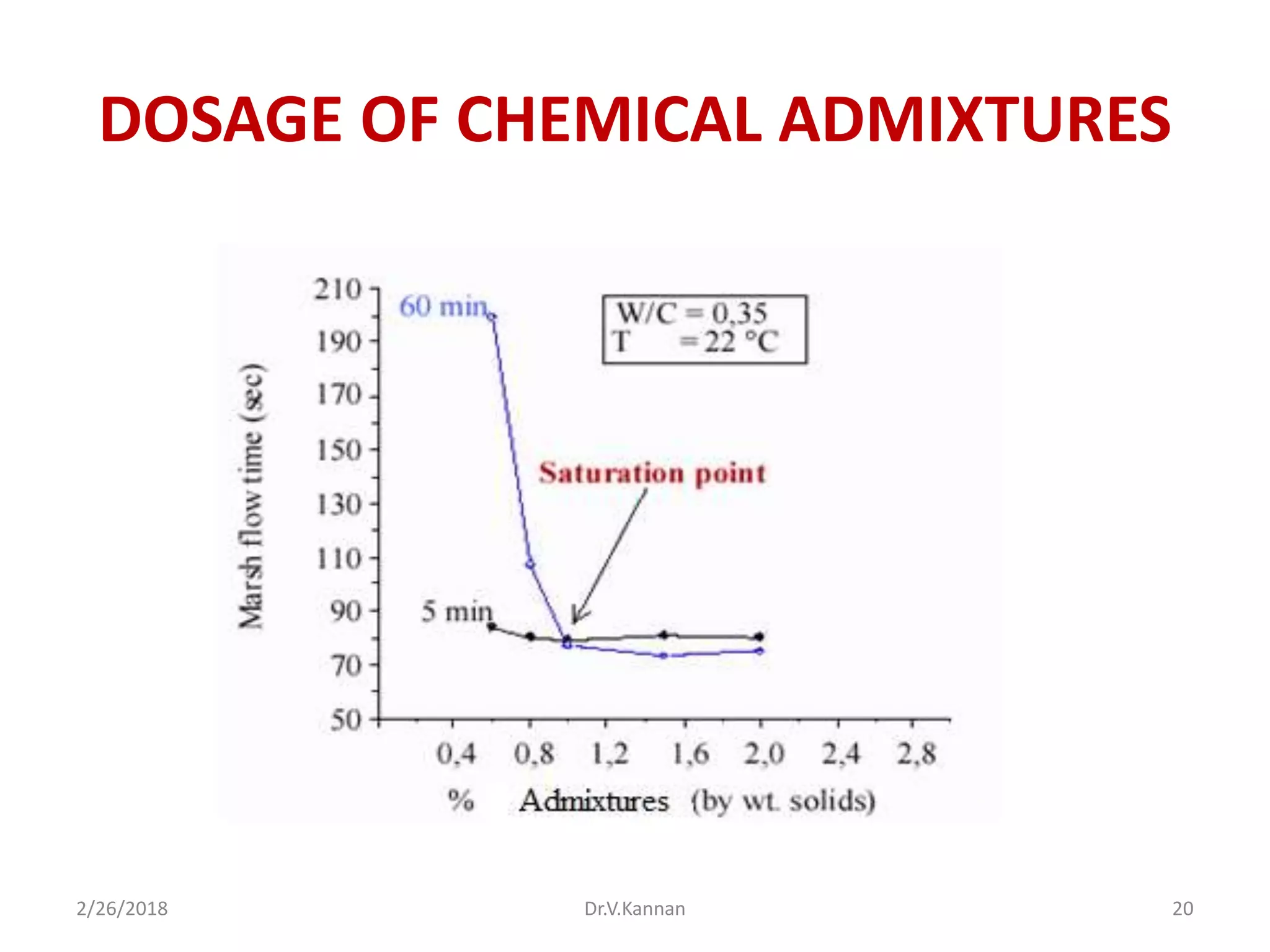

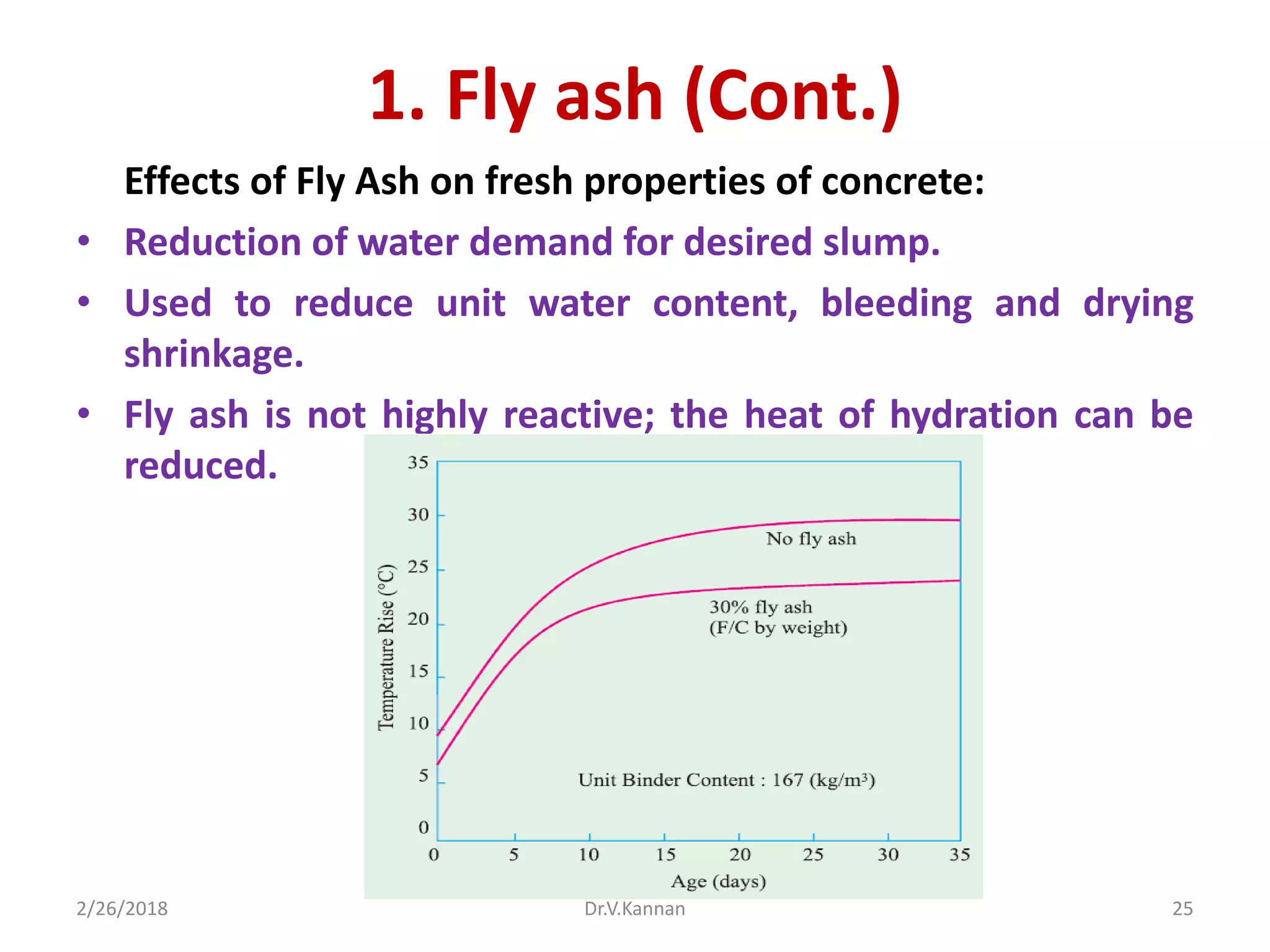

The document provides an overview of concrete admixtures, which are materials added to concrete to modify its properties in both fresh and hardened states. It categorizes admixtures into chemical (like accelerators and retarders) and mineral types (such as fly ash and silica fume), detailing their effects on workability, strength, and durability. Additionally, it discusses specifics like water reducers, their classifications, and the influence of various admixtures on concrete performance.