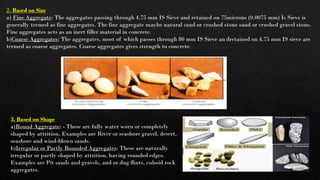

This document contains information about aggregates used in concrete provided by Deblina Dutta, a third year civil engineering student. It discusses the classification, properties, and uses of aggregates. Aggregates make up 70-80% of concrete by volume and include natural materials like sand, gravel, and crushed stone. They are classified based on their geological origin, size, shape, and unit weight. The properties of aggregates like composition, size, surface texture, specific gravity, bulk density, voids, porosity, absorption, and fineness modulus affect the properties of concrete. Aggregates are an important part of concrete as they give it body, make it economical, and contribute to its mechanical strength.