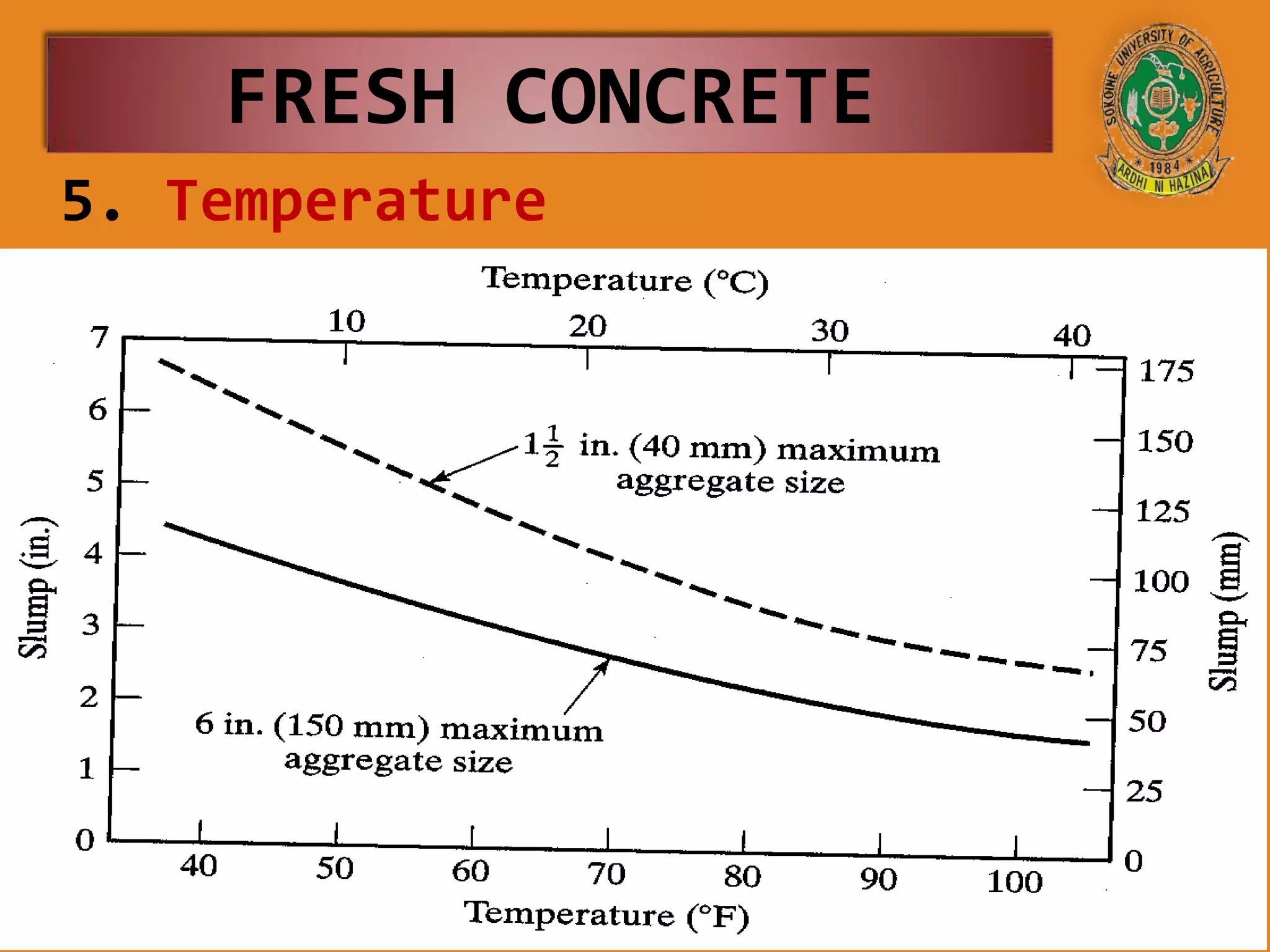

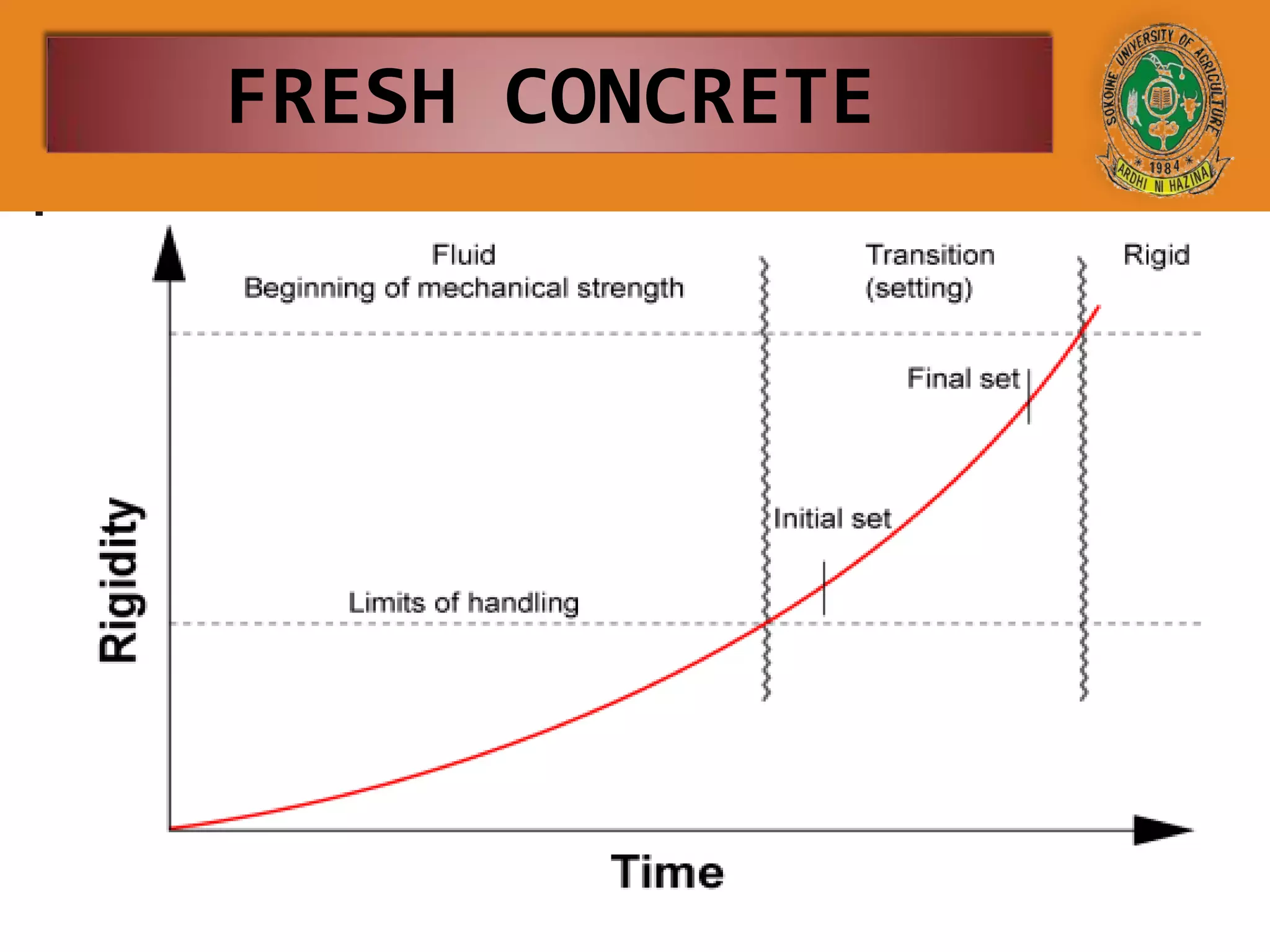

The document provides an overview of fresh concrete, including its properties, testing methods, and factors affecting its performance, such as workability, slump loss, and segregation. It emphasizes the importance of proper mixing, curing, and the use of admixtures to enhance the concrete's characteristics. Additionally, it discusses various testing methods for assessing workability and strength of fresh concrete, along with the role of different types of admixtures.