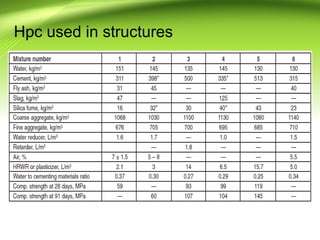

This document provides an overview of high performance concrete (HPC). It defines HPC as concrete with high durability and strength compared to conventional concrete, containing cementious materials like fly ash or slag and superplasticizers. The document outlines the history of concrete, properties of HPC like strength and durability, structures it can be used in, and benefits like reduced costs and maintenance needs. It also discusses setting time, durability characteristics, when to use HPC, types of HPC, and limitations before concluding that HPC is crucial for tall buildings due to its strength, durability, and ability to withstand severe environments.