The document discusses top-down construction, which is required when:

1) The distance between existing buildings and the new building line is small, requiring deep excavation and risking soil collapse.

2) It allows for more building and basement area, suitable for two or more basements.

3) The first basement slab acts as a strut, preventing soil collapse behind retaining walls.

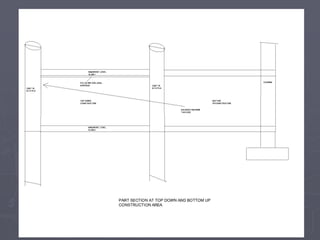

The methodology involves:

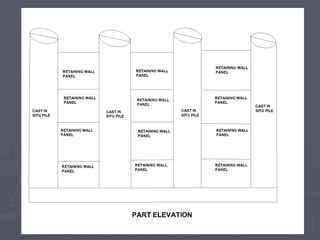

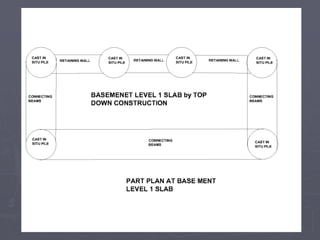

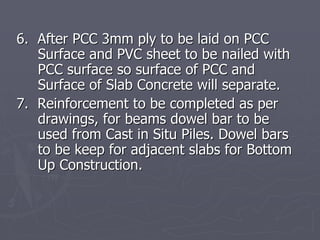

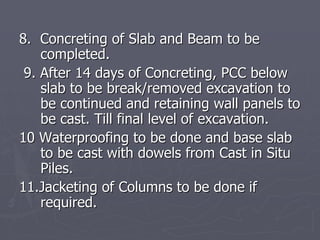

1) Casting piles with dowels for retaining walls and slabs.

2) Excavating in stages and casting retaining wall panels with dowels between piles.

3) Pouring the first basement slab and then continuing excavation and construction from the bottom up