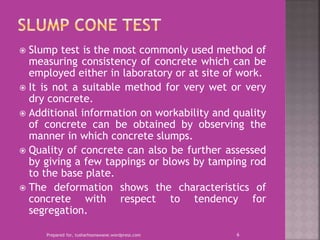

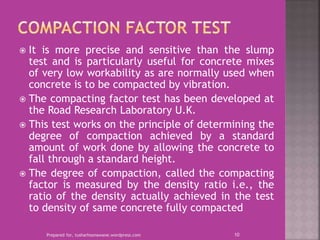

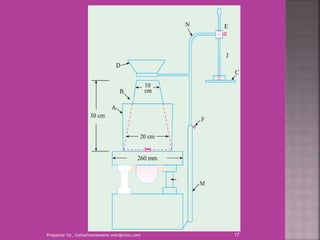

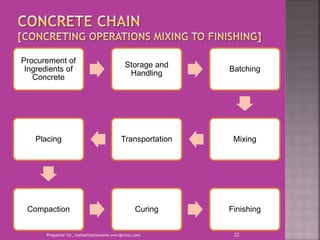

This document outlines the properties and testing methods of fresh concrete, focusing on workability, segregation, and bleeding. It discusses various testing techniques including slump tests, compacting factor tests, and Vee-Bee consistometer tests. Additionally, the document details the processes involved in concrete procurement, mixing, transportation, placing, compaction, and curing.

![ Mixing

Mixing plays an important role in as far as

concreting work is concerned.

It can be done by two ways

A. Hand Mixing – Mixing done by hand

B. Machine Mixing – Mixing done using mechanical mixers

The mechanical mixers can be more efficient and

produces uniform mix.

Types of mixers

The tilting drum type [Rotating]

The non tilting type [Rotating]

Pan type mixer

The paddle type

Prepared for, tusharhsonawane.wordpress.com 25](https://image.slidesharecdn.com/fresh-concrete-180201094951/85/Fresh-concrete-25-320.jpg)