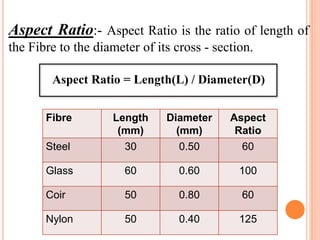

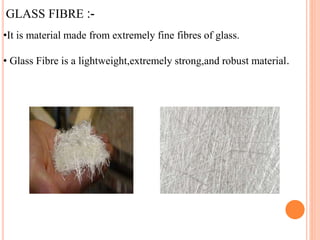

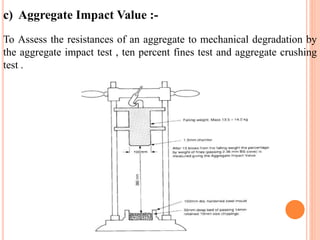

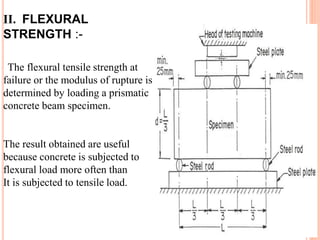

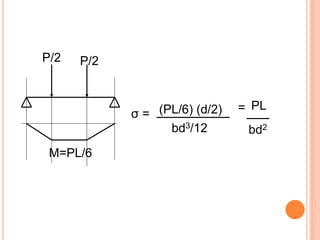

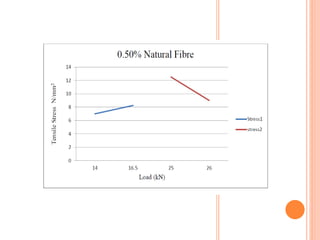

This document summarizes research on the durability of fibre reinforced concrete. It discusses how fibres can improve the properties of concrete, including increased tensile strength and resistance to cracking. It outlines the methodology of the research, which involves testing concrete reinforced with different types and amounts of fibres, including steel, glass, natural and artificial fibres. The research examines the effect of fibres on the compressive and flexural strength of concrete beams. It also evaluates the durability of fibre reinforced concrete exposed to chloride and sulfate attacks. The results indicate that natural fibre reinforced concrete has the highest tensile strength and best durability. The research concludes that fibre reinforcement improves concrete properties and durability.