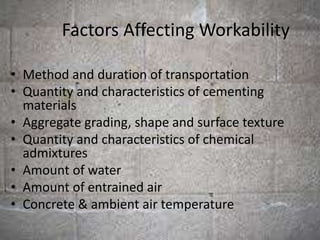

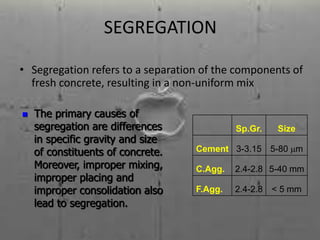

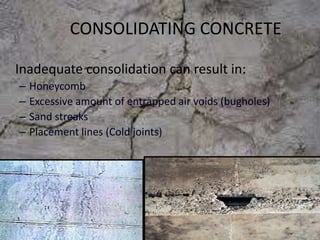

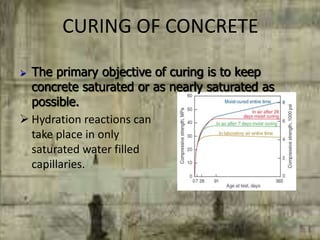

Concrete is a composite material made of aggregates, sand, cement and water. It has many useful properties such as versatility, durability and fire resistance which make it widely used in construction. Fresh concrete must have adequate workability and consistency to be properly mixed, placed and consolidated. Proper curing is also important to allow the cement to fully hydrate and gain strength over time. While concrete has advantages, it also has disadvantages like low tensile strength and requires careful mixing to ensure uniformity.