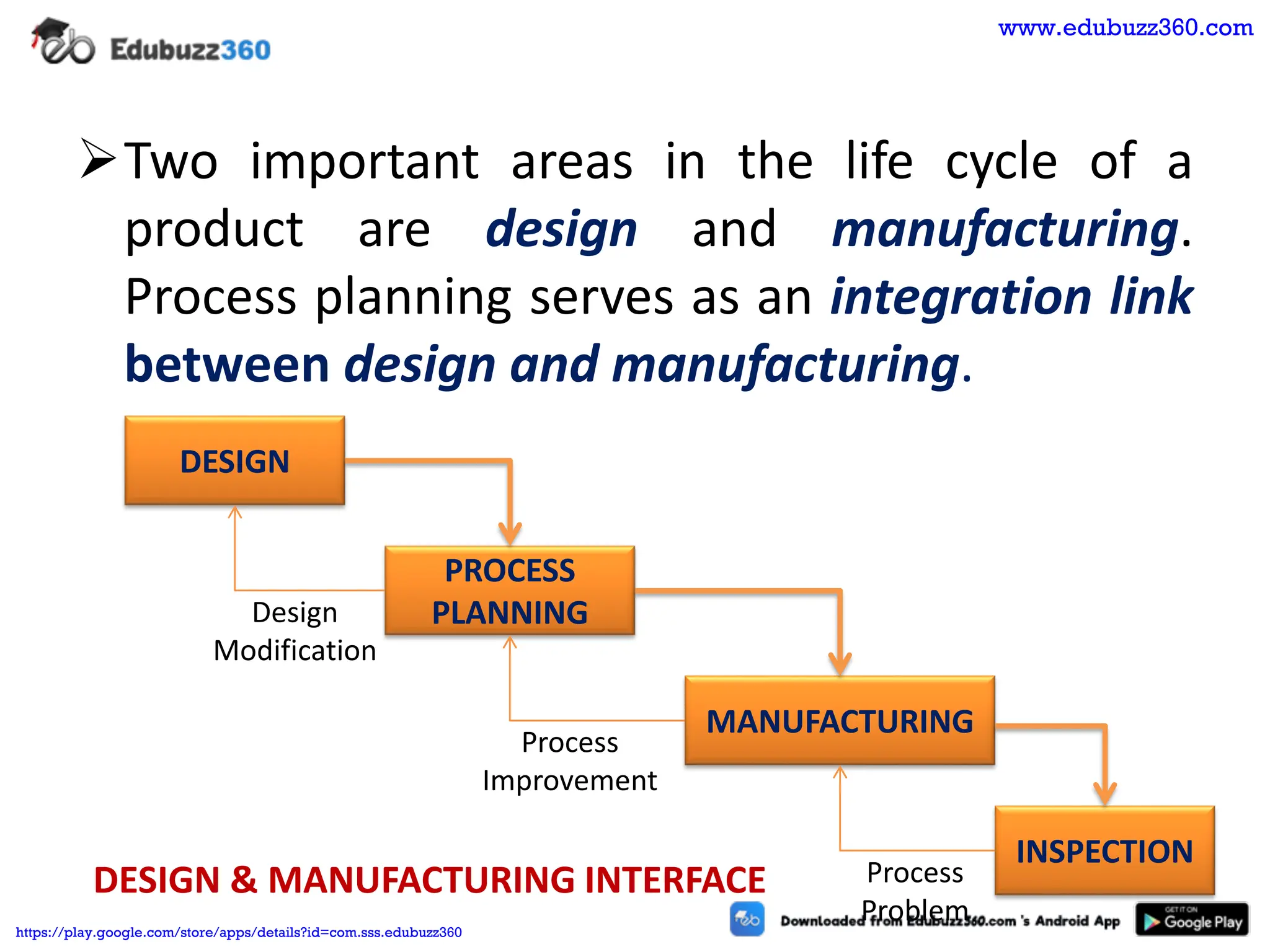

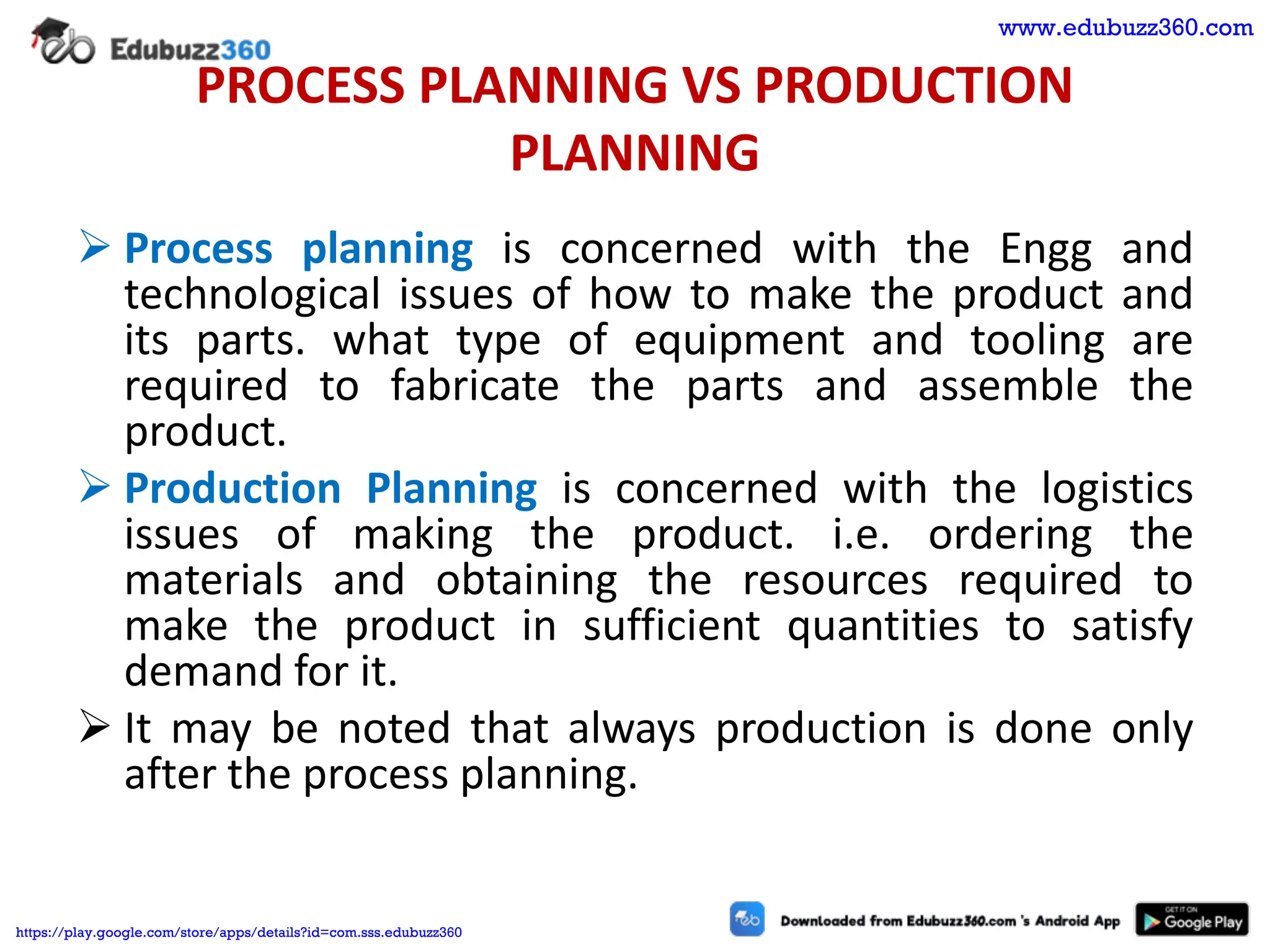

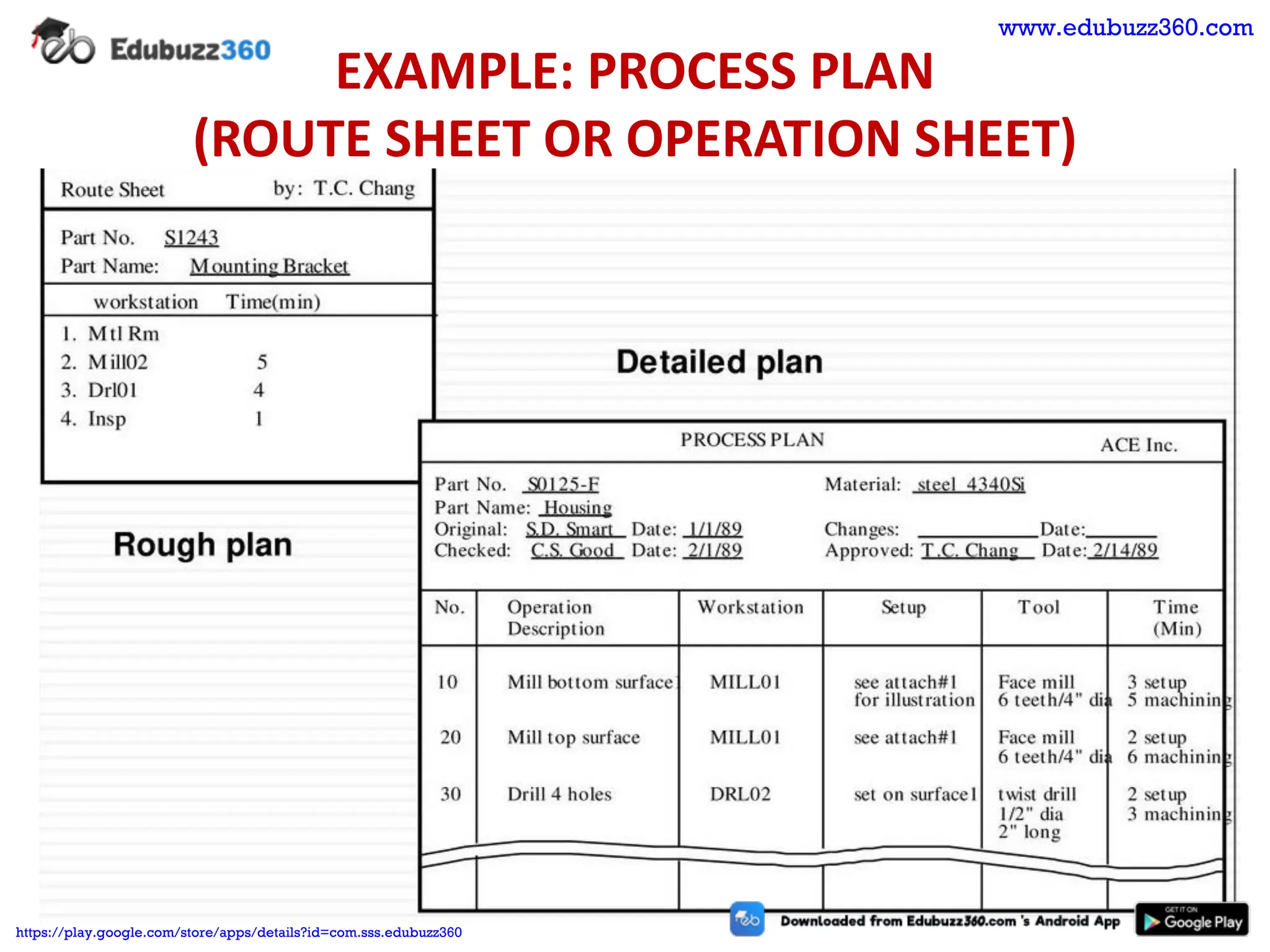

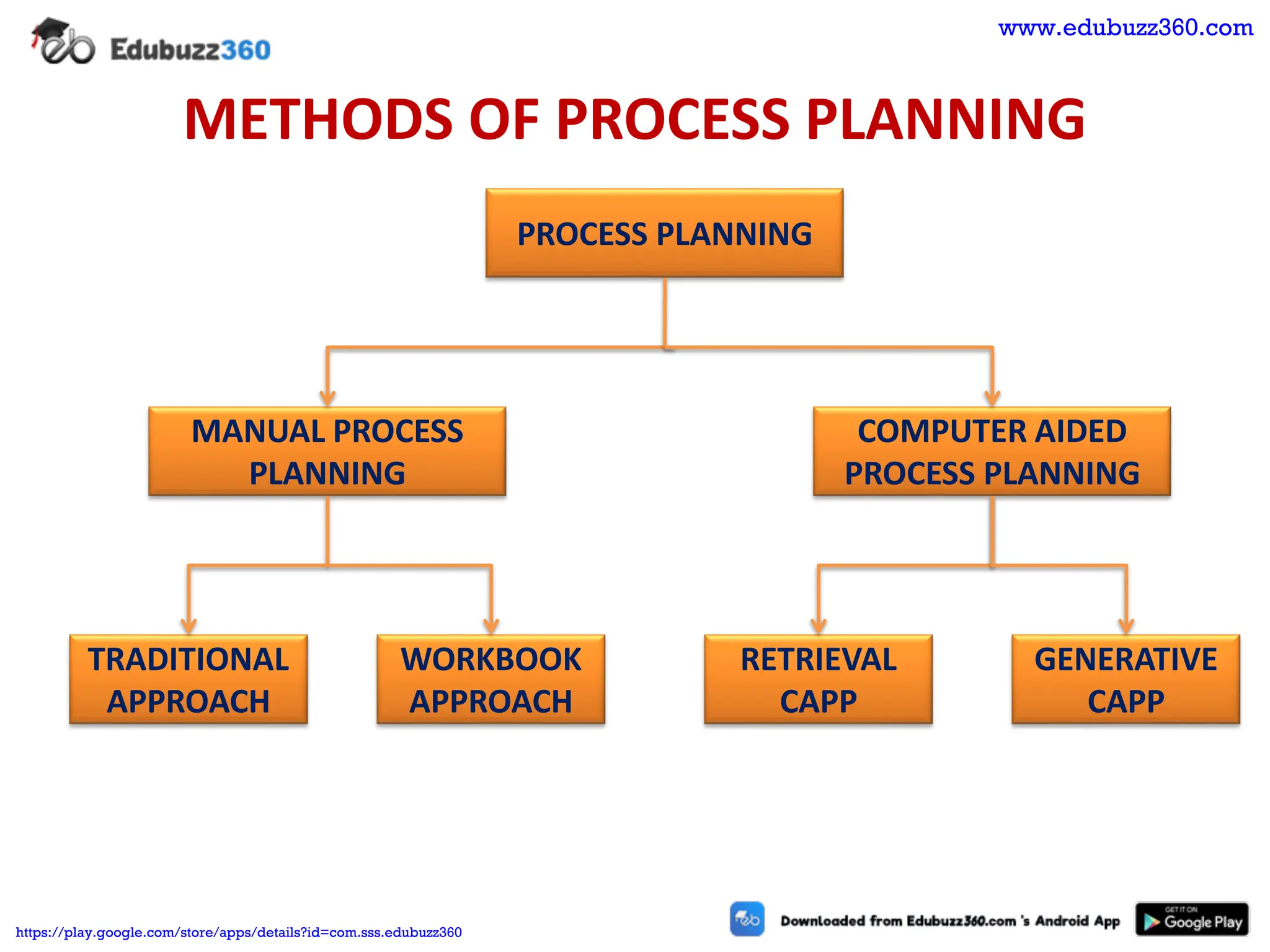

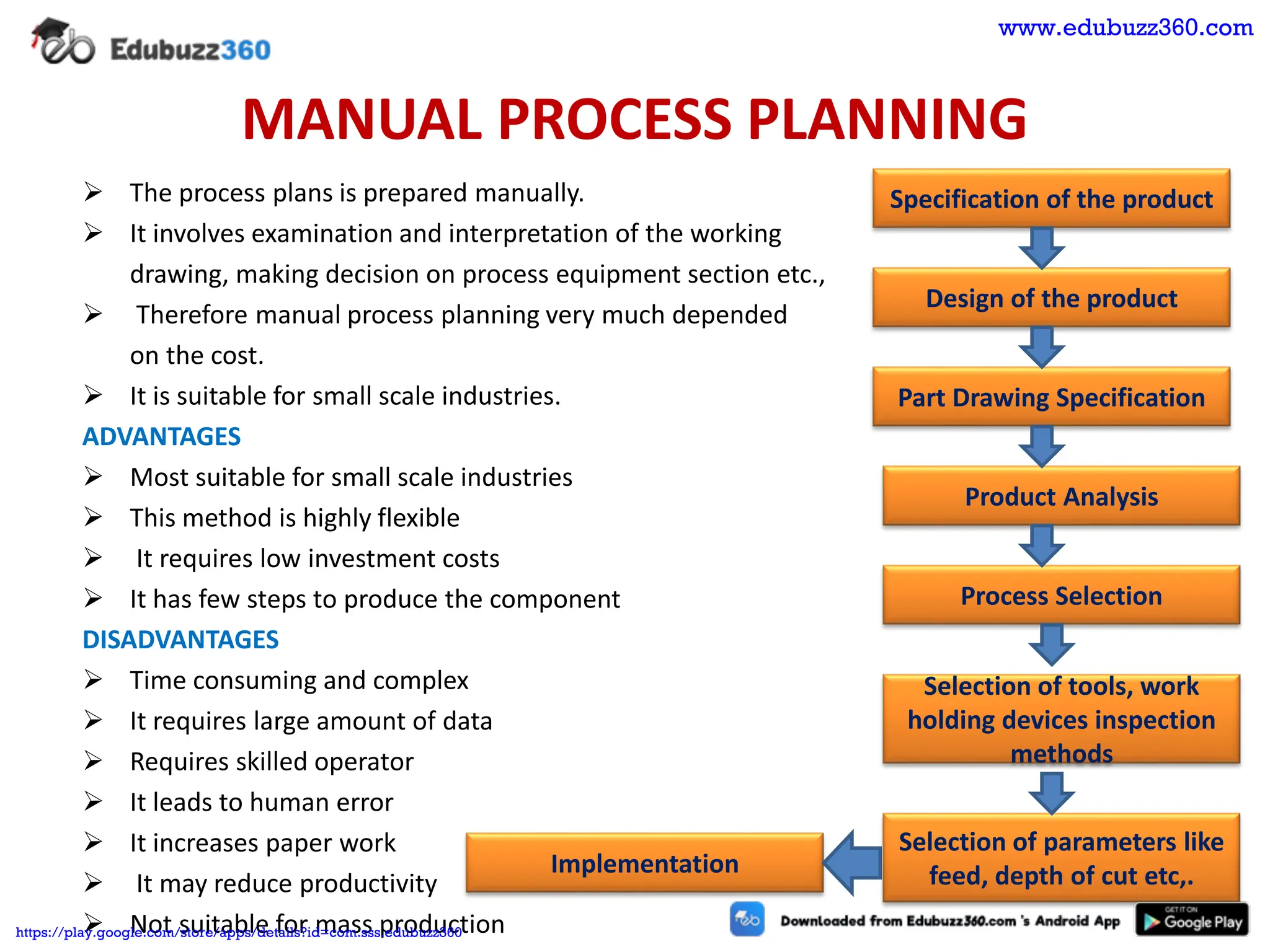

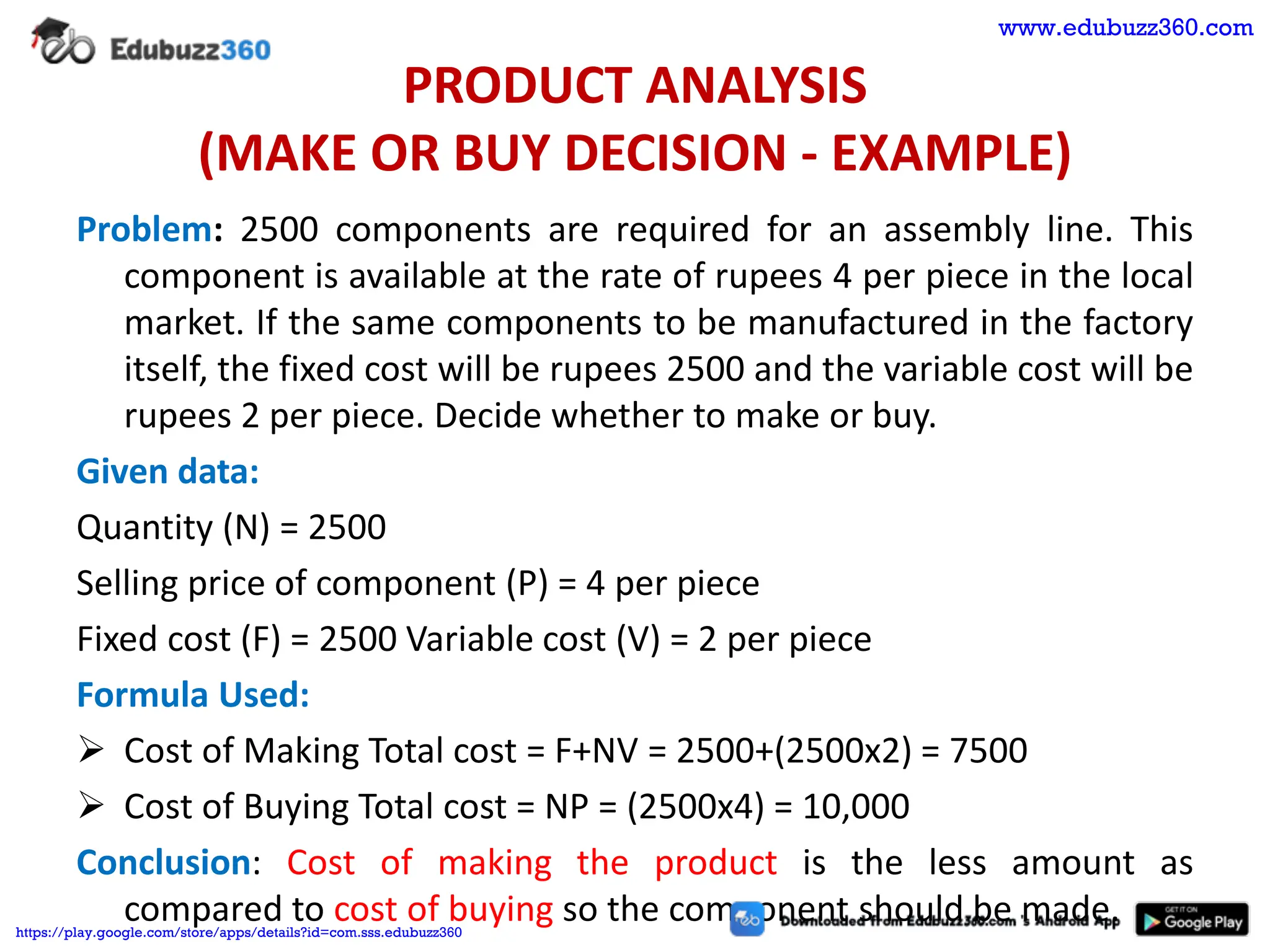

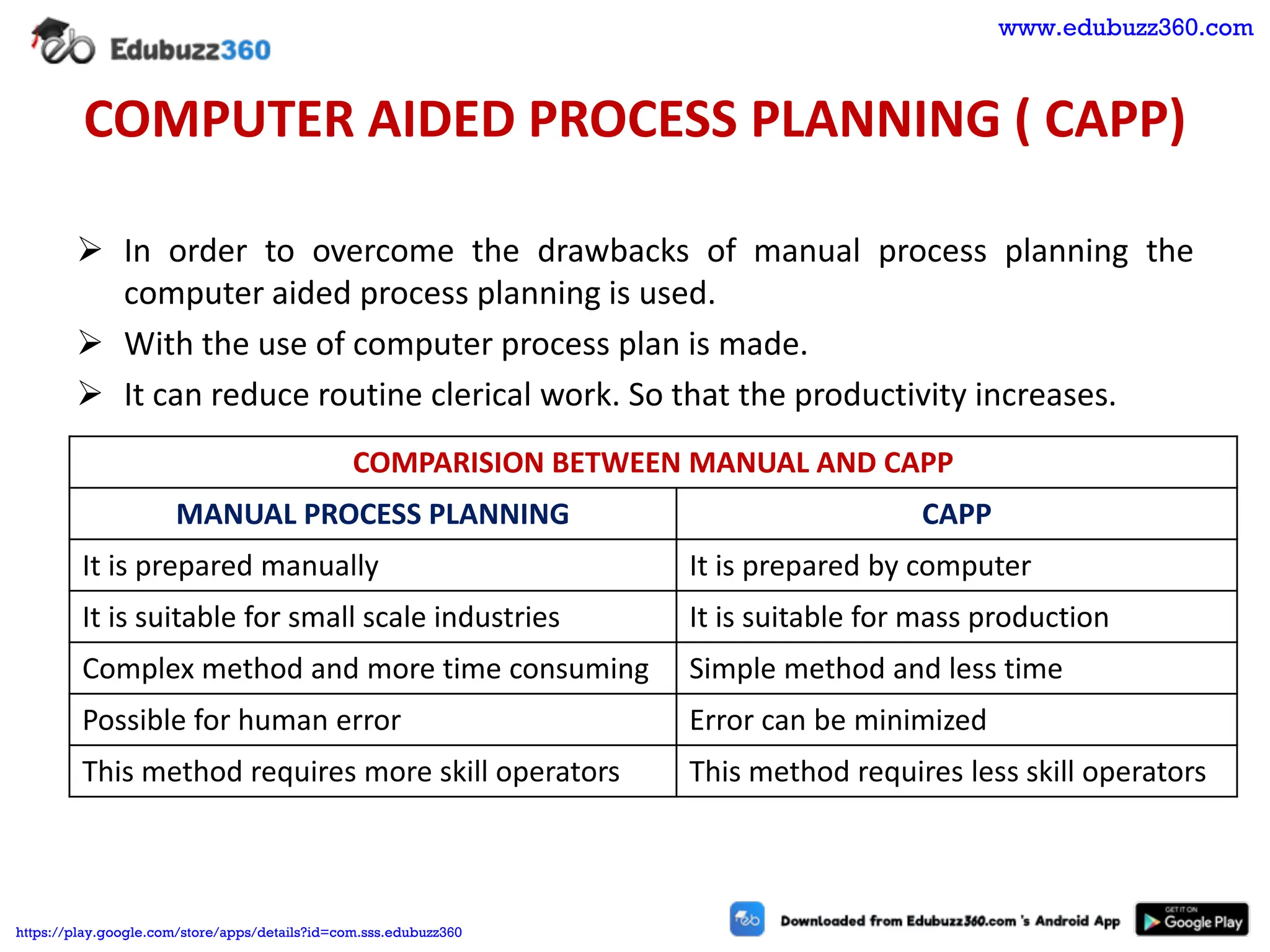

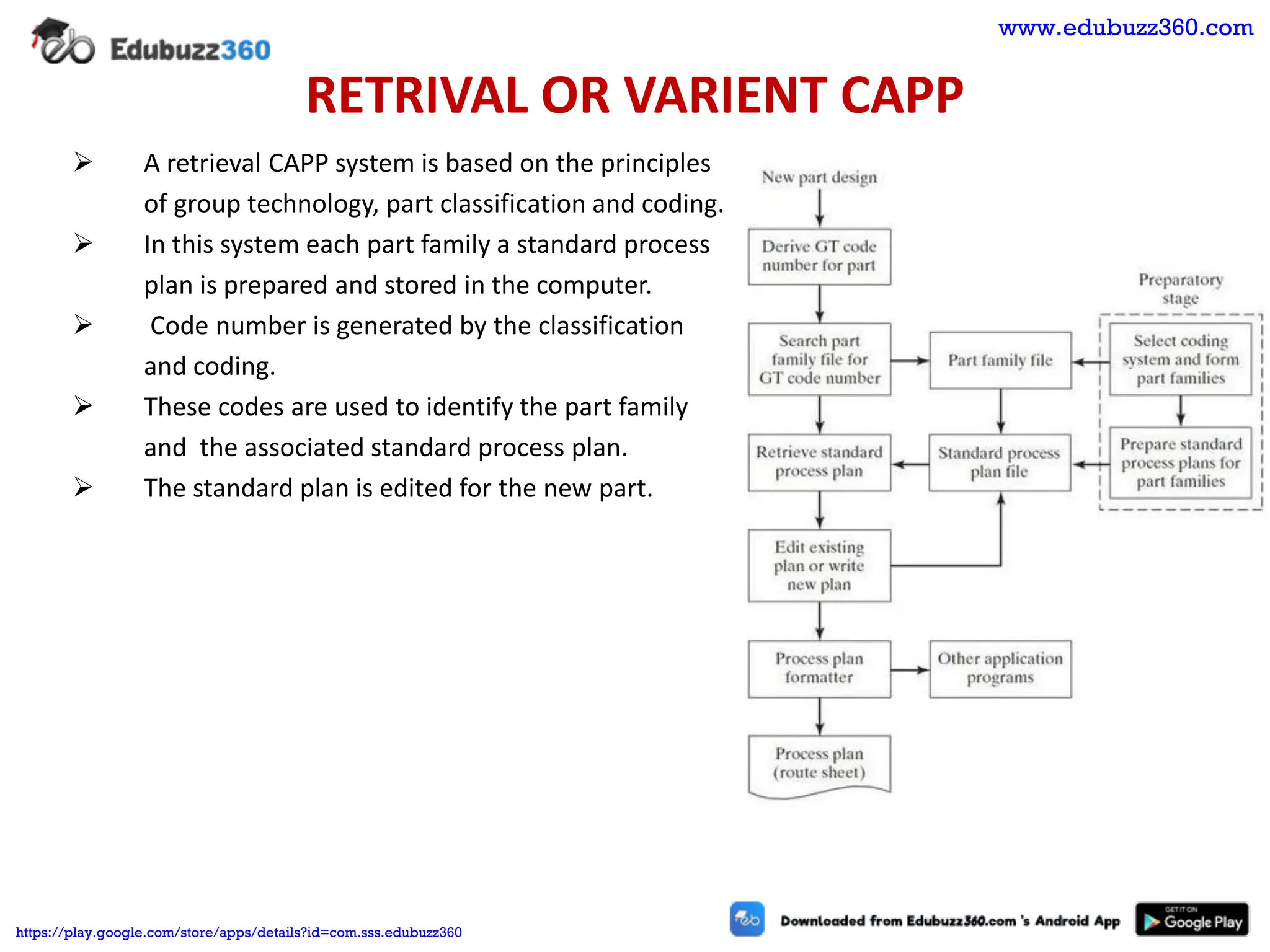

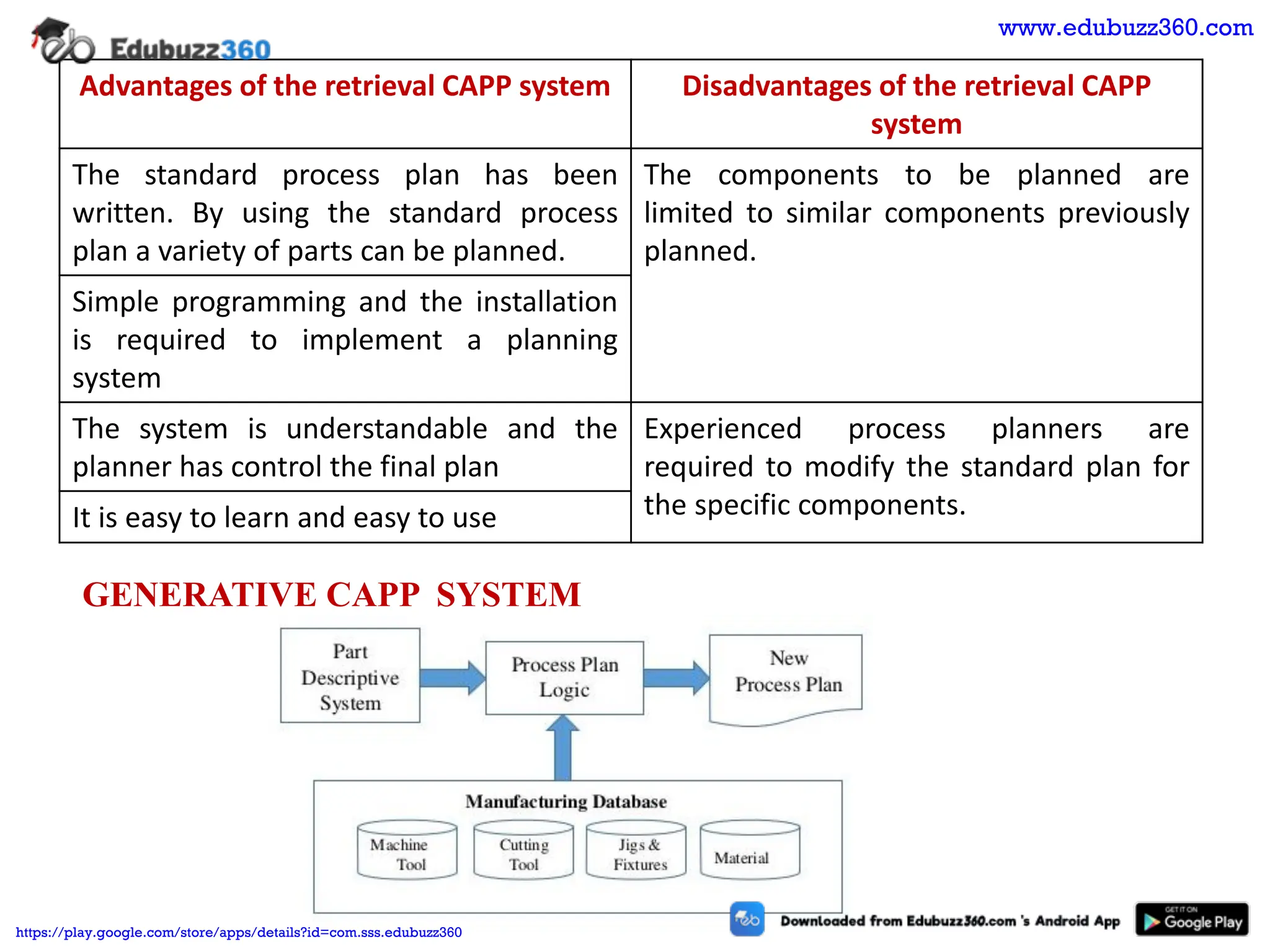

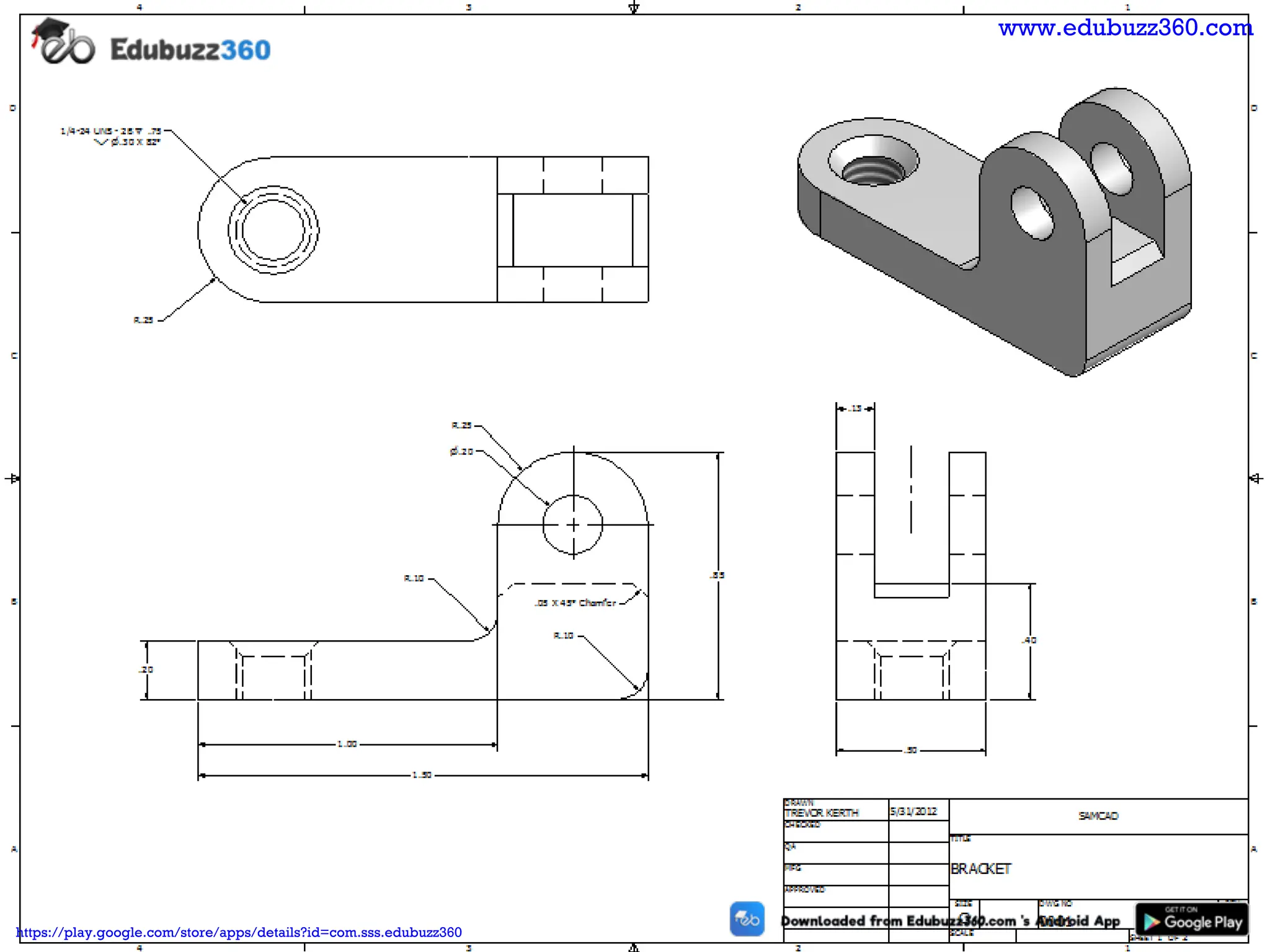

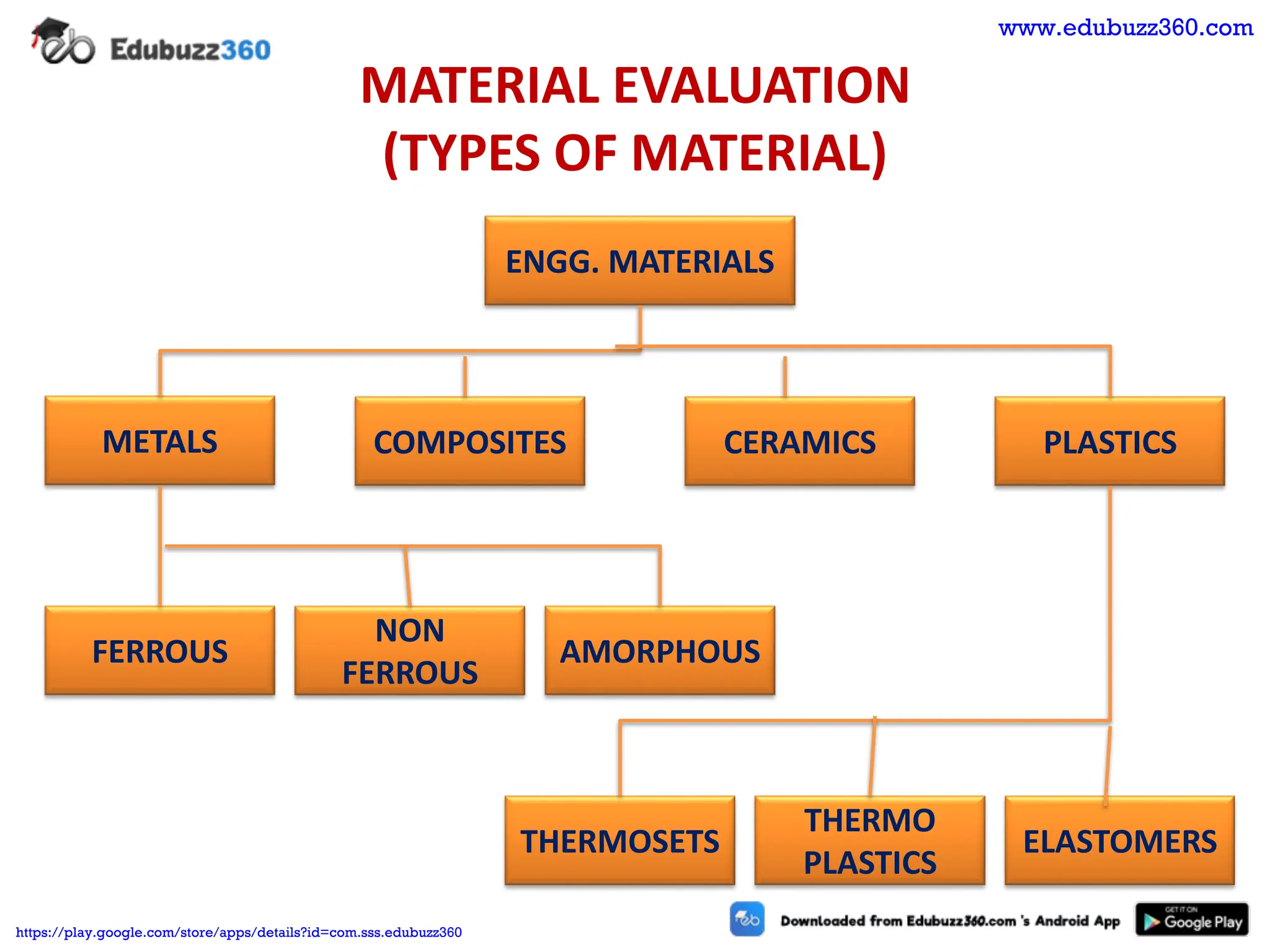

The document discusses process planning and cost estimation for mechanical engineering. It defines process planning as the systematic determination of manufacturing methods to produce a product economically and competitively. Process planning involves integrating design, manufacturing, assembly, distribution, service, and disposal. It serves as the link between design and manufacturing. The document outlines various process planning techniques including manual, computer-aided, and generative methods. It also covers topics like drawing interpretation, material evaluation, and cost estimation.