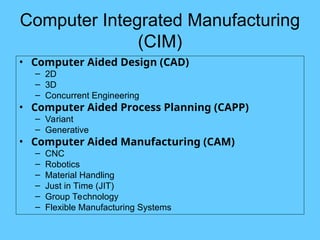

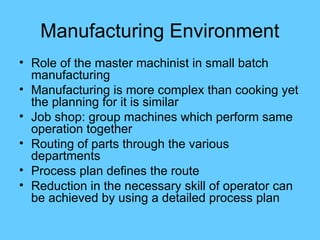

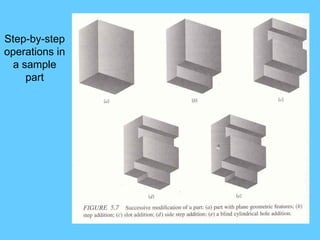

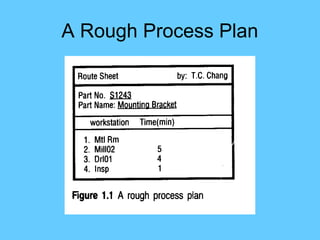

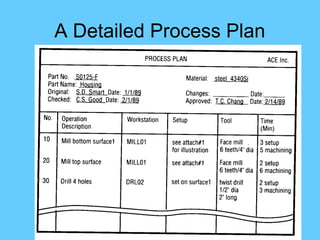

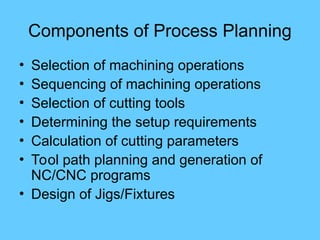

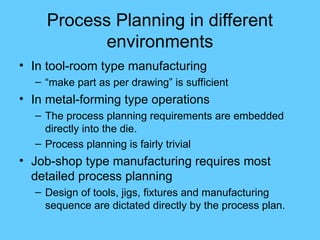

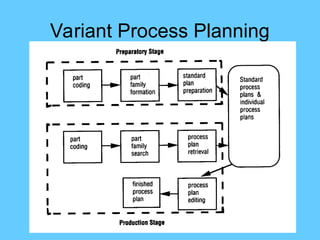

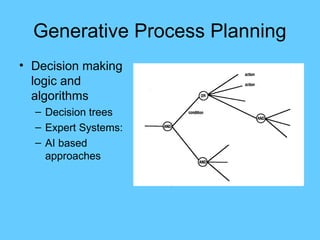

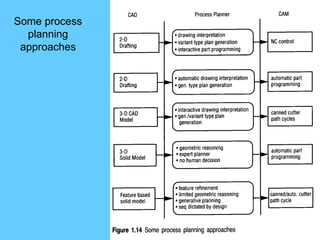

The document discusses computer-aided process planning (CAPP) within computer integrated manufacturing (CIM), highlighting various methodologies like variant and generative planning. It emphasizes the significance of detailed process plans to improve manufacturing efficiency, reduce costs, and mitigate the reliance on skilled labor. Additionally, it outlines the implementation of group technology (GT) and the use of software tools to enhance competitive advantage in manufacturing.