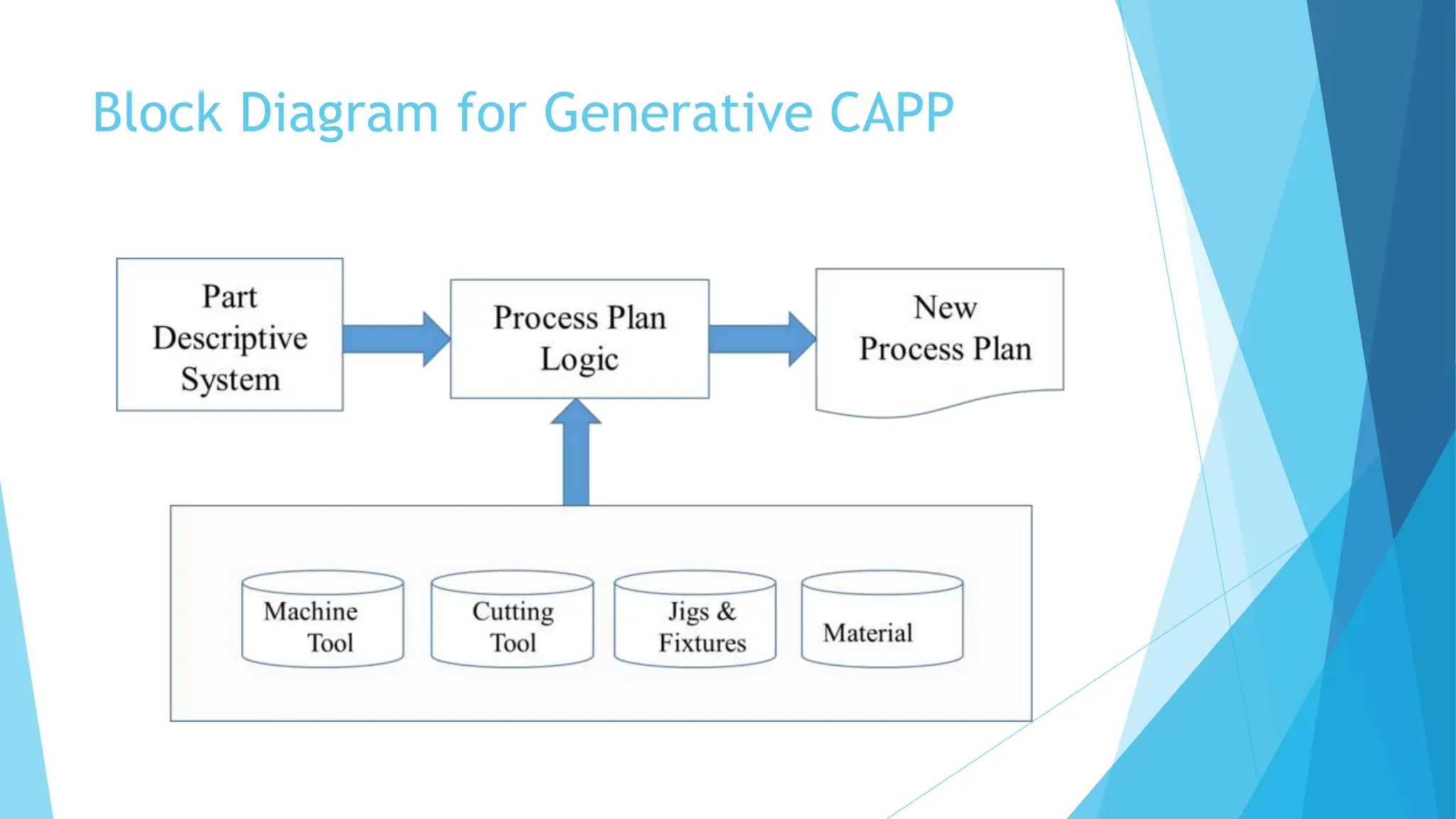

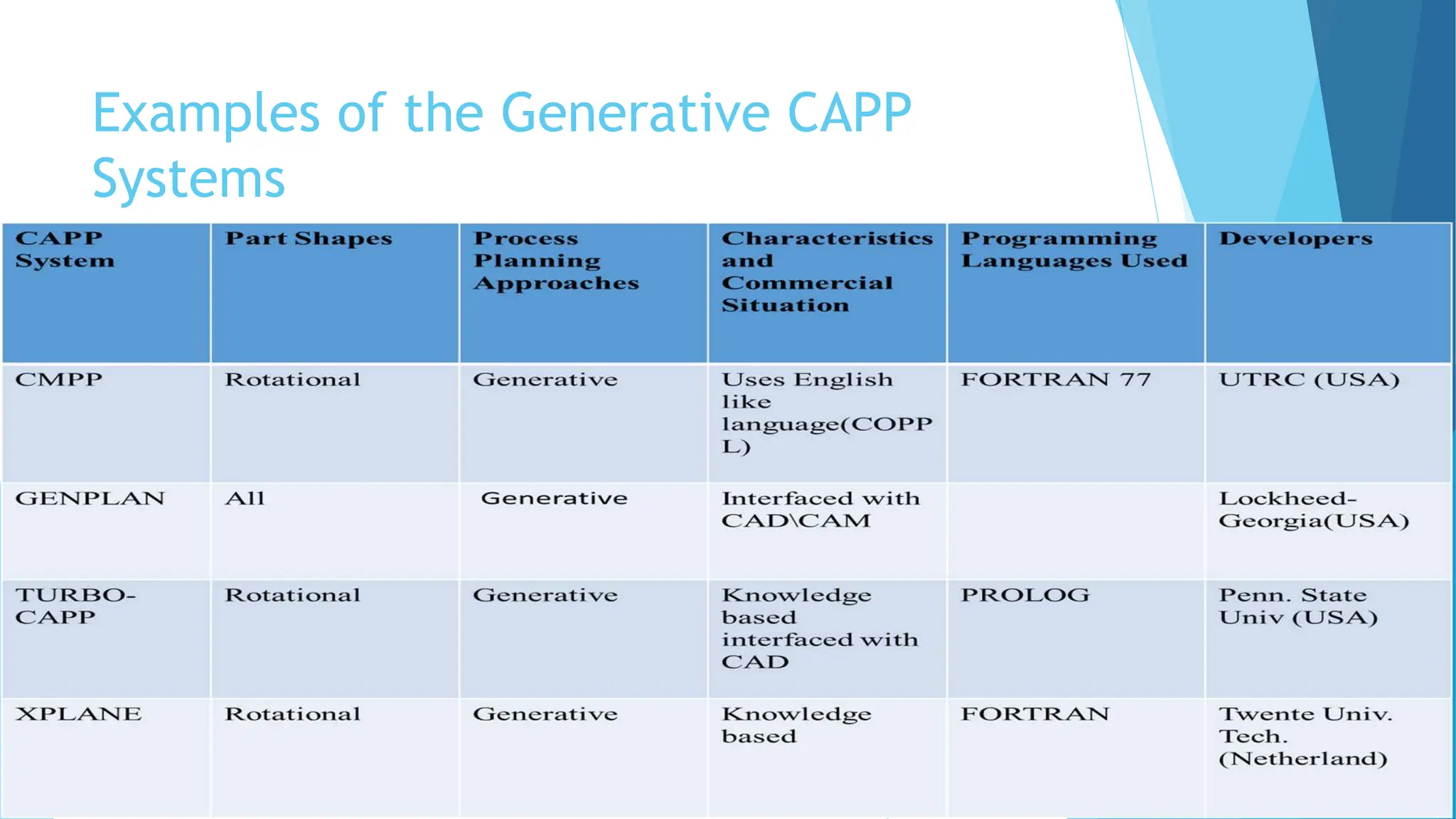

The document discusses Computer Aided Process Planning (CAPP), which automates the generation of machining operation sequences to reduce reliance on individual planners' judgments. It outlines two approaches: variant systems and generative process planning (GPP), with GPP creating plans from scratch utilizing algorithms based on detailed geometric and process knowledge. The advantages of generative CAPP include process rationalization, increased productivity, faster planning, improved document clarity, and software integration, while its drawbacks are complexity and high development costs.