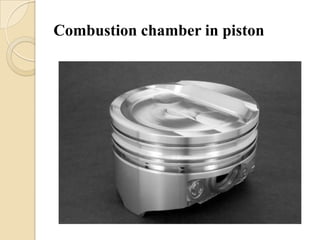

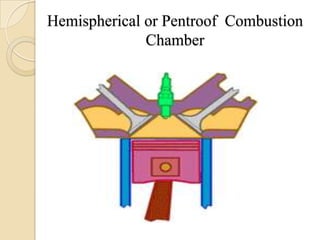

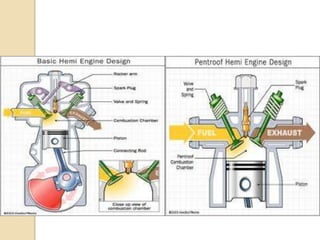

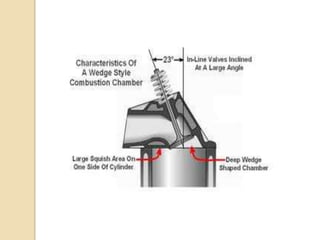

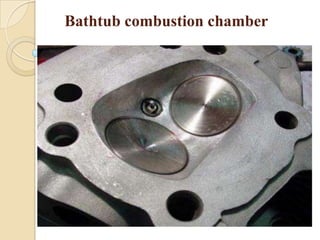

The combustion chamber is the area inside the engine where the fuel-air mixture is compressed and ignited. It is located between the cylinder head and the piston. Different combustion chamber designs include hemispherical, wedge-shaped, and bathtub chambers. The shape of the chamber affects power, efficiency, and emissions by influencing factors like fuel-air mixing, flame propagation, and heat transfer.