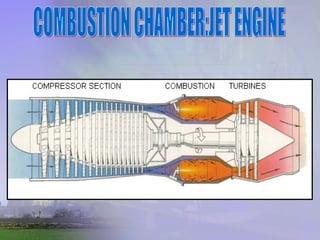

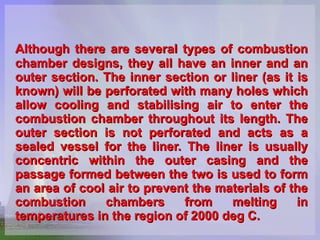

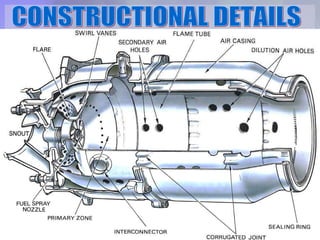

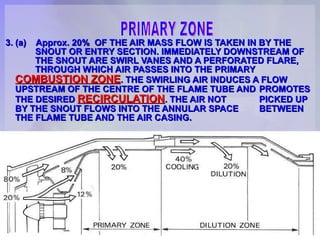

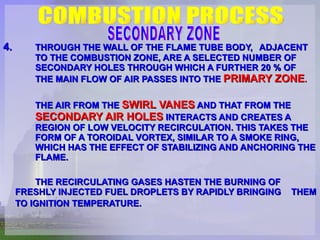

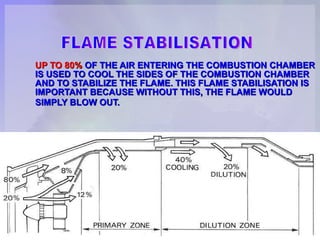

The document summarizes the combustion chamber of a jet engine. It discusses how an air-fuel mixture burns inside the combustion chamber and how proper combustion and stabilization of the flame are essential for optimum engine power. It also describes the various requirements of a combustion chamber, including maintaining stable combustion over a wide range of operating conditions, high combustion efficiency, withstanding high temperatures, and minimizing pressure loss during combustion.