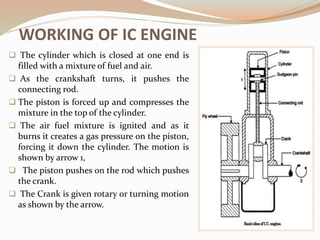

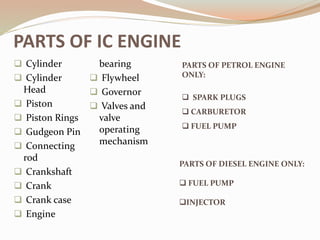

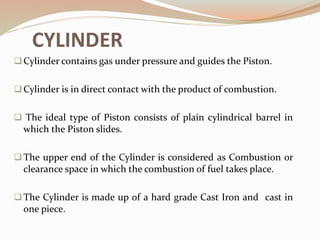

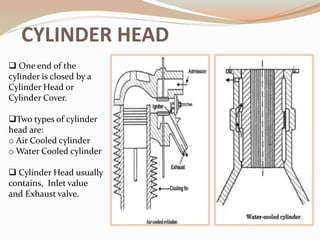

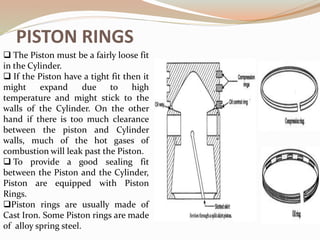

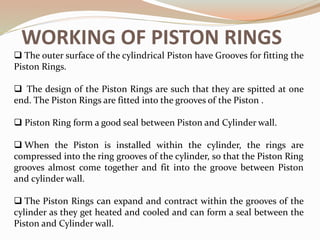

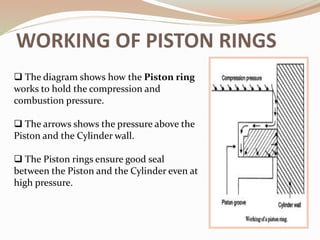

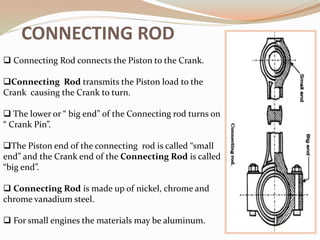

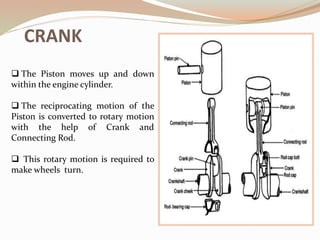

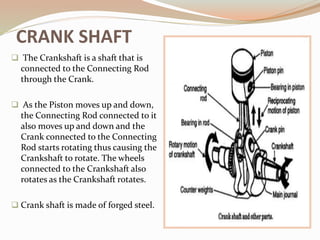

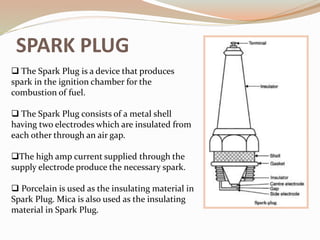

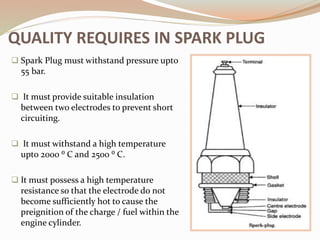

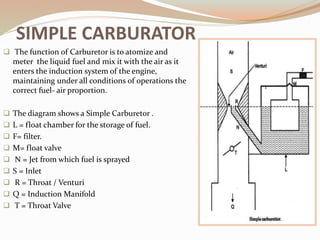

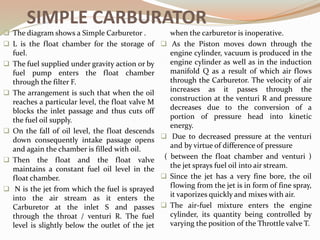

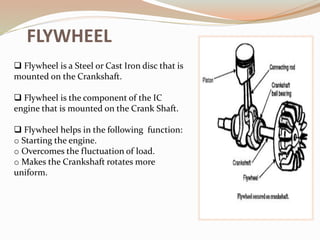

The document discusses internal combustion engines. It defines heat engines and describes how internal combustion engines work by combusting fuel within the engine cylinder. It then discusses the basic components of internal combustion engines like the cylinder, piston, connecting rod, crankshaft, intake and exhaust valves. It provides classifications of IC engines based on their cycle of operation and combustion cycle. It also summarizes the working of common engine components like the spark plug, carburetor, flywheel and governor.