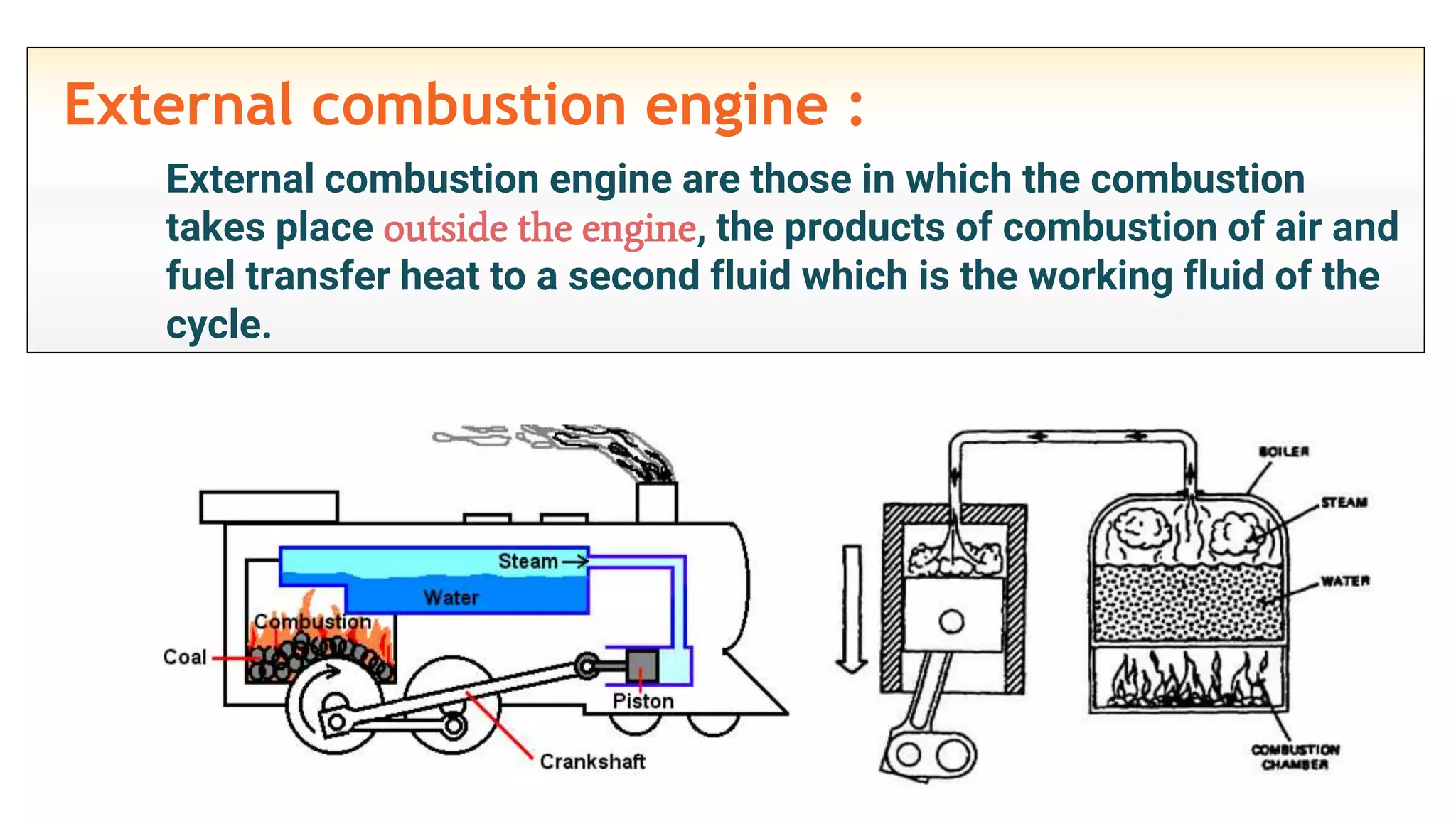

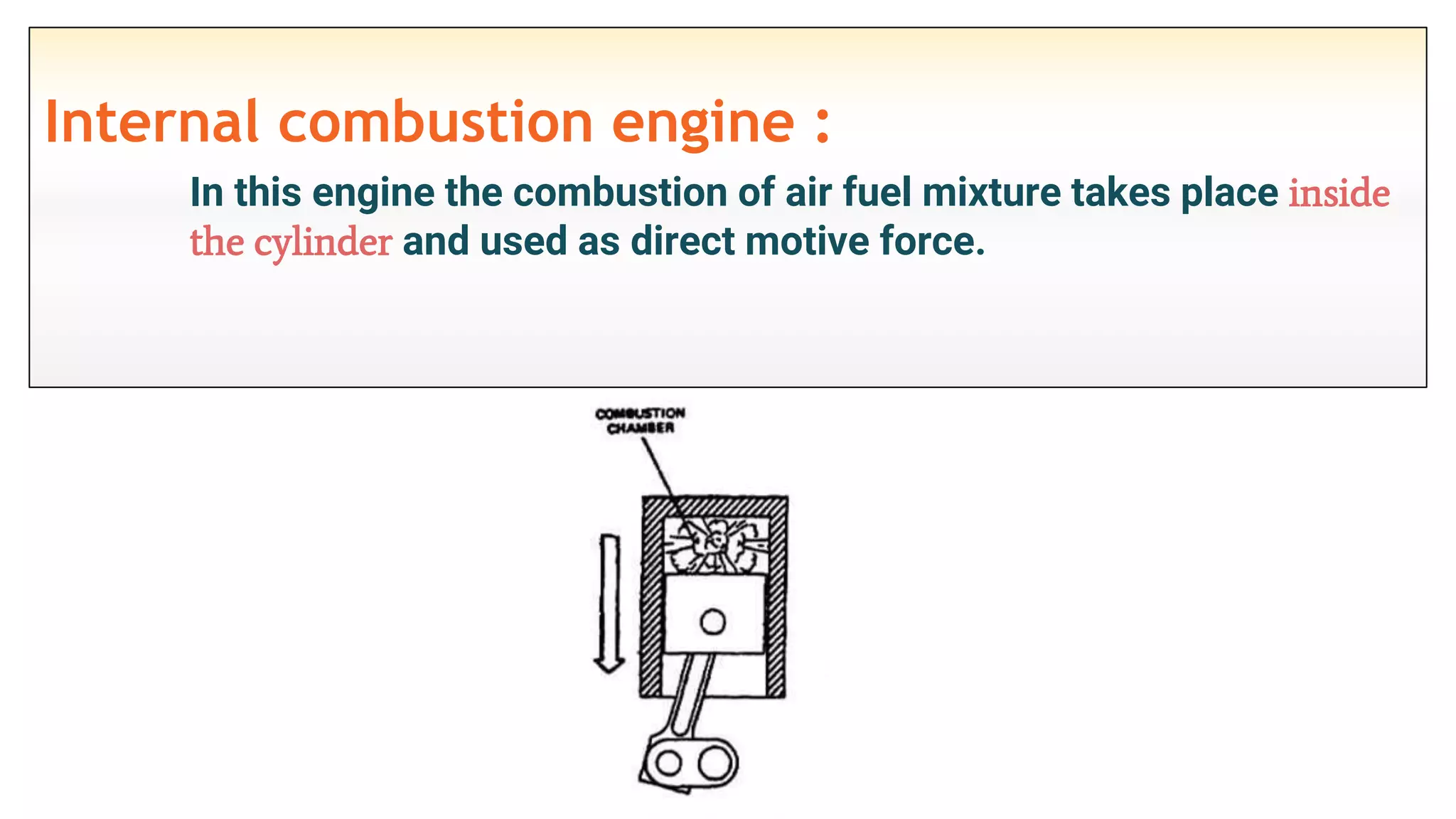

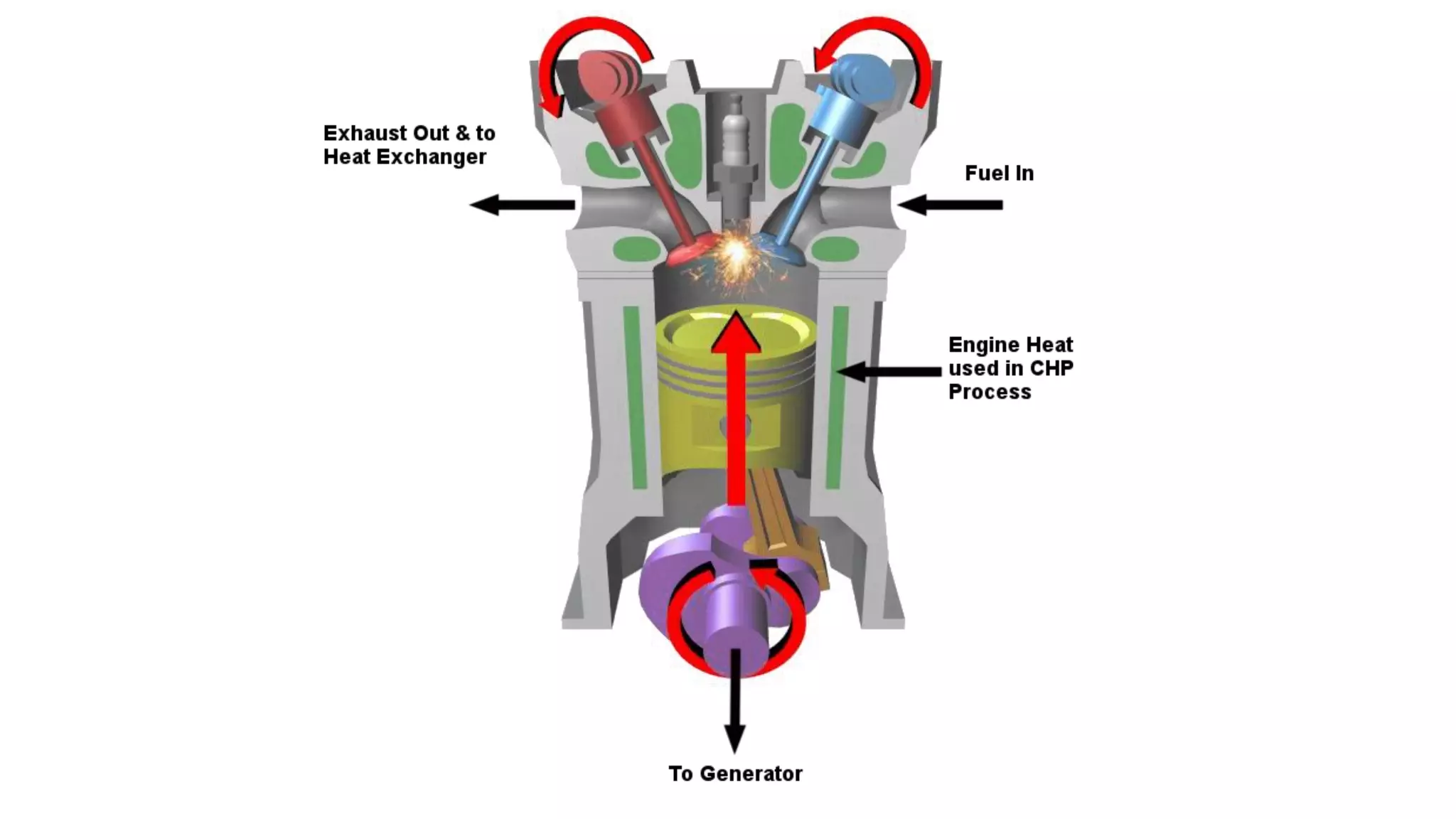

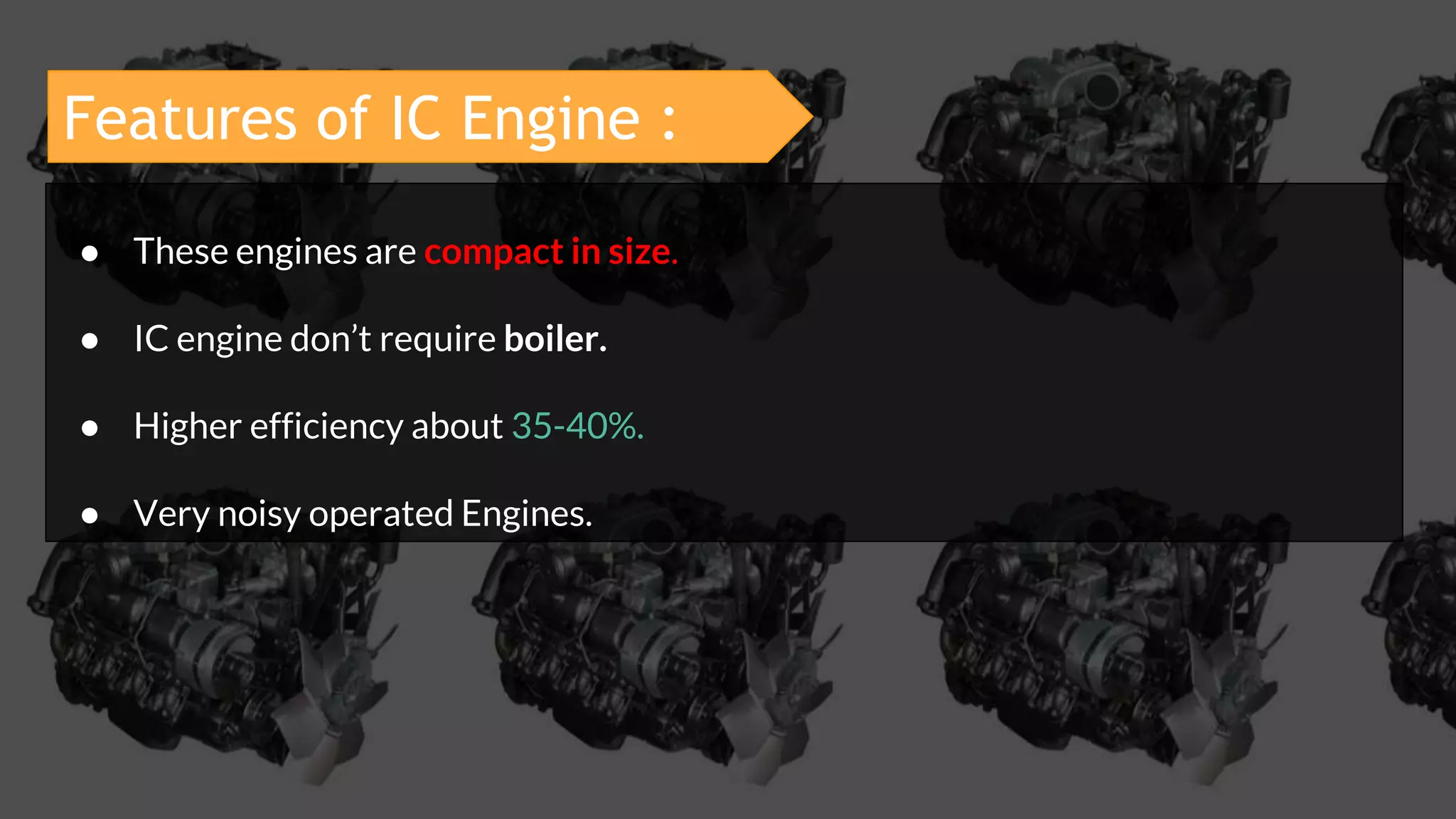

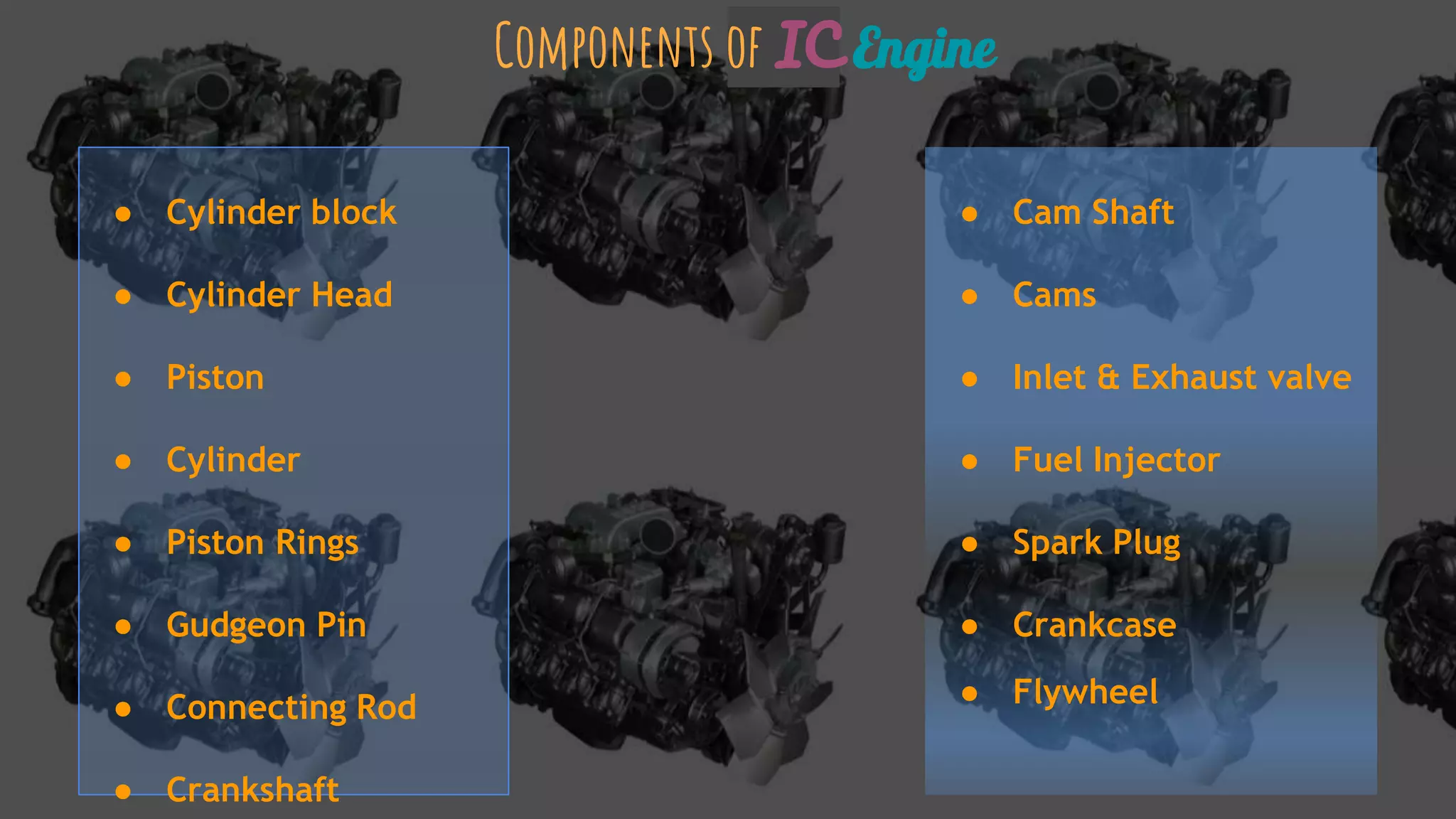

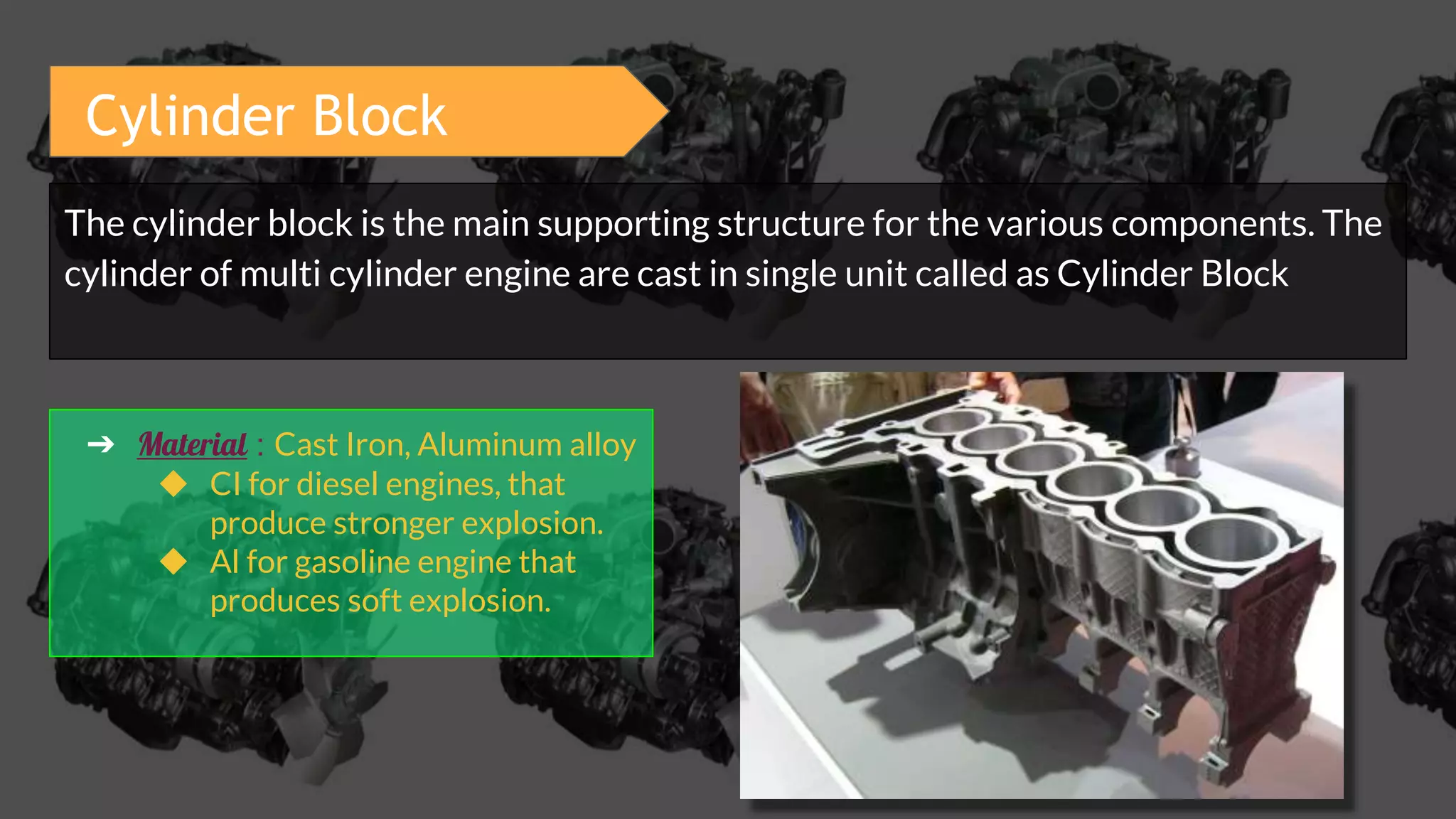

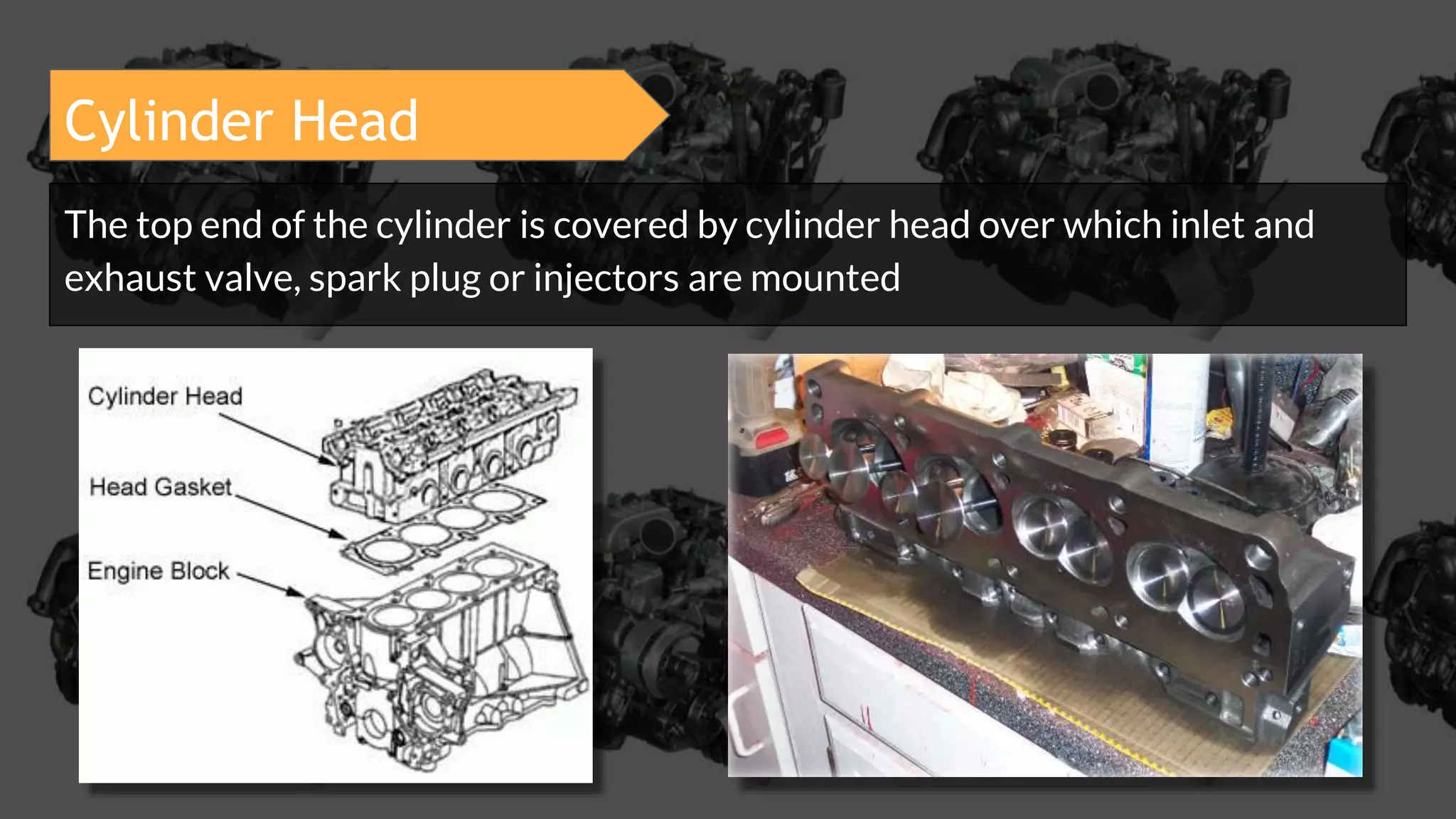

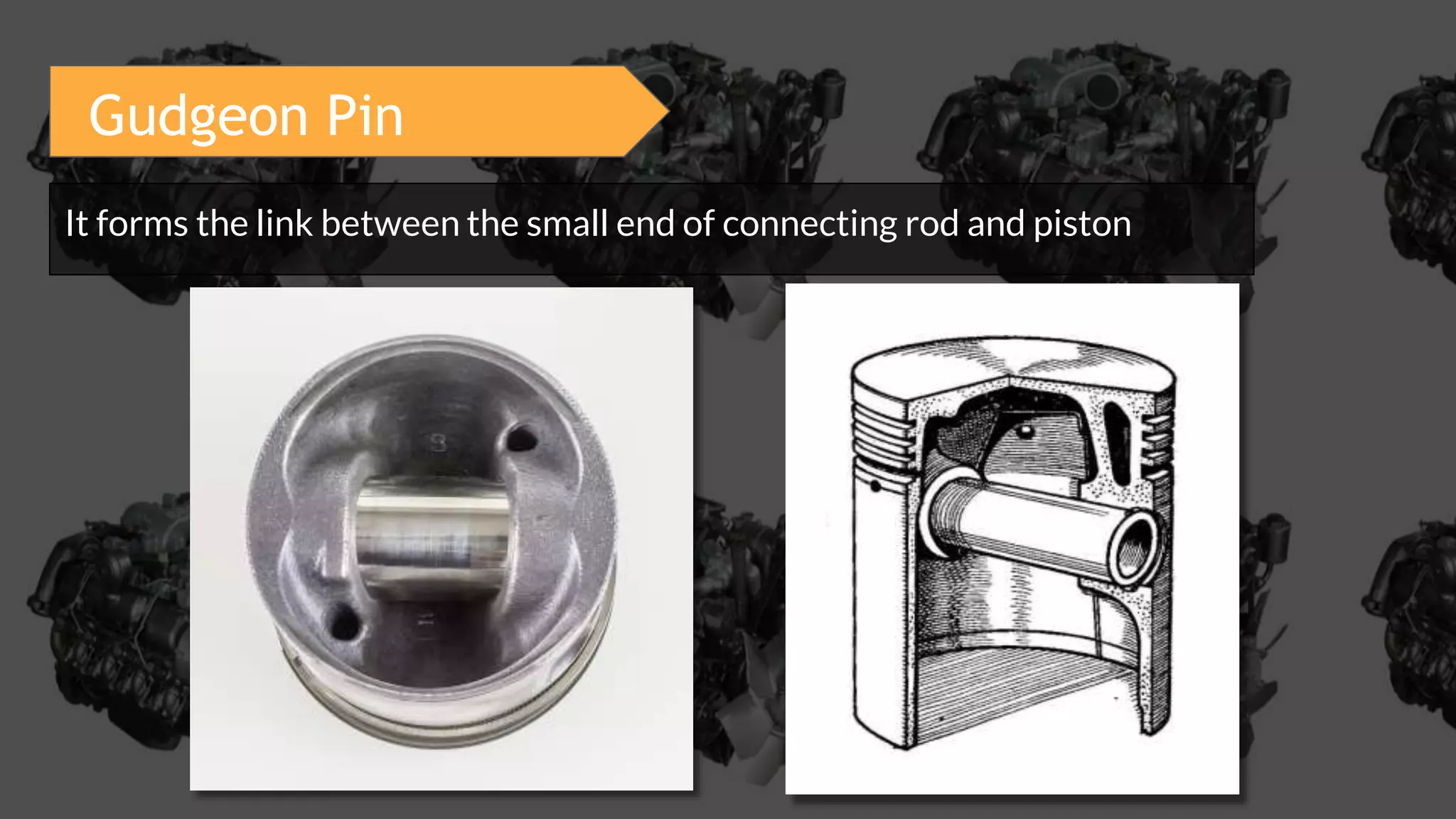

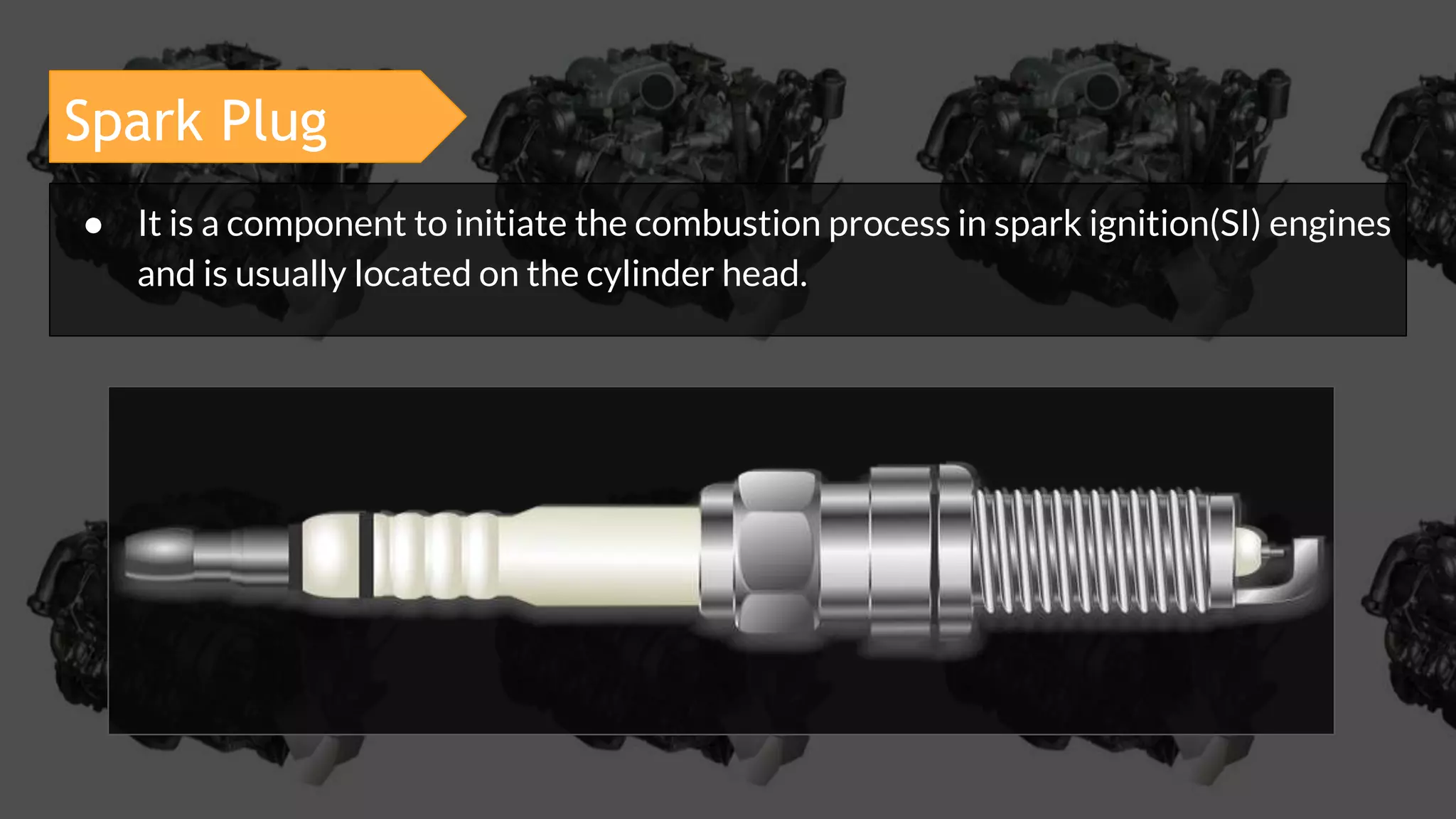

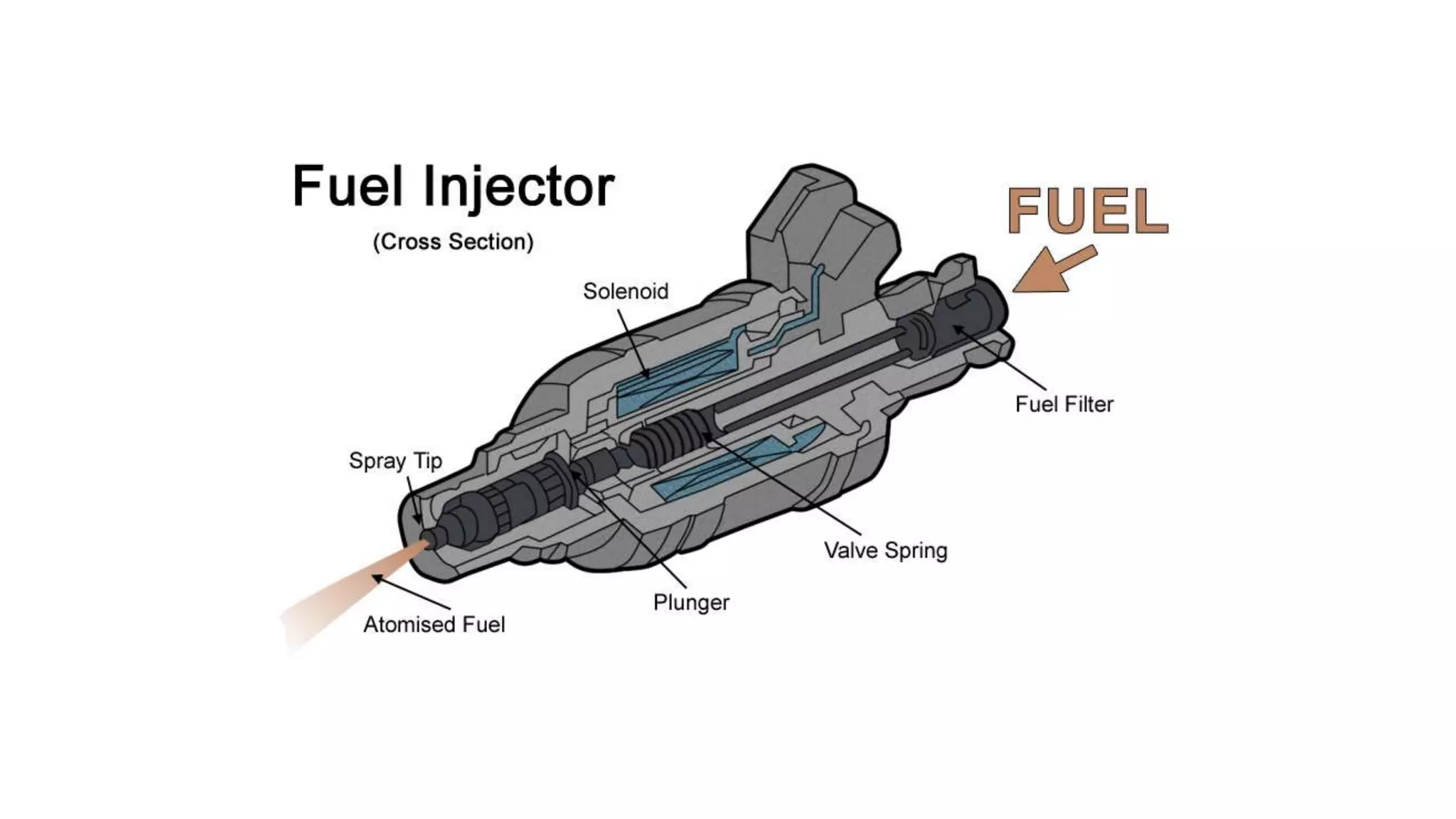

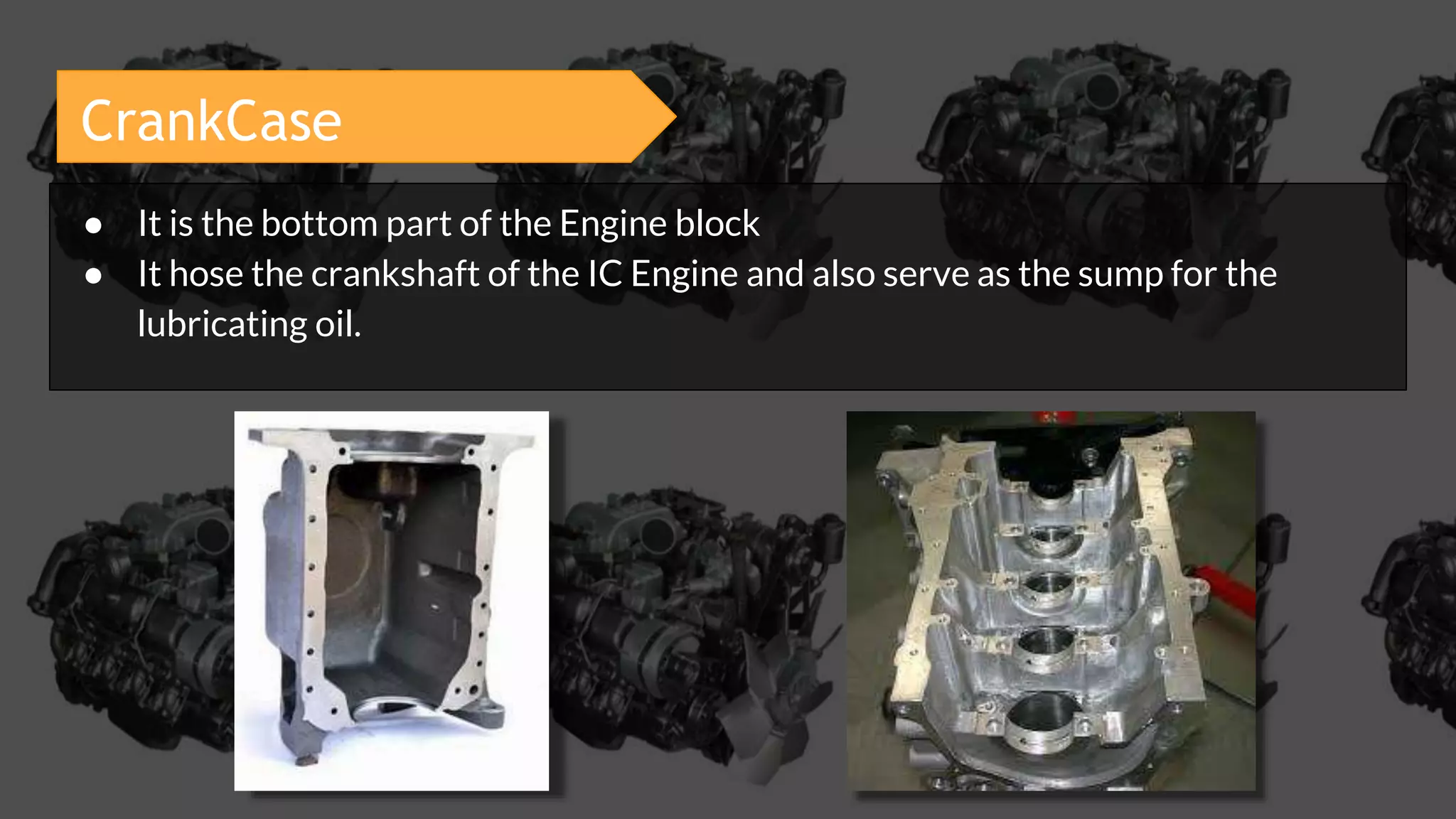

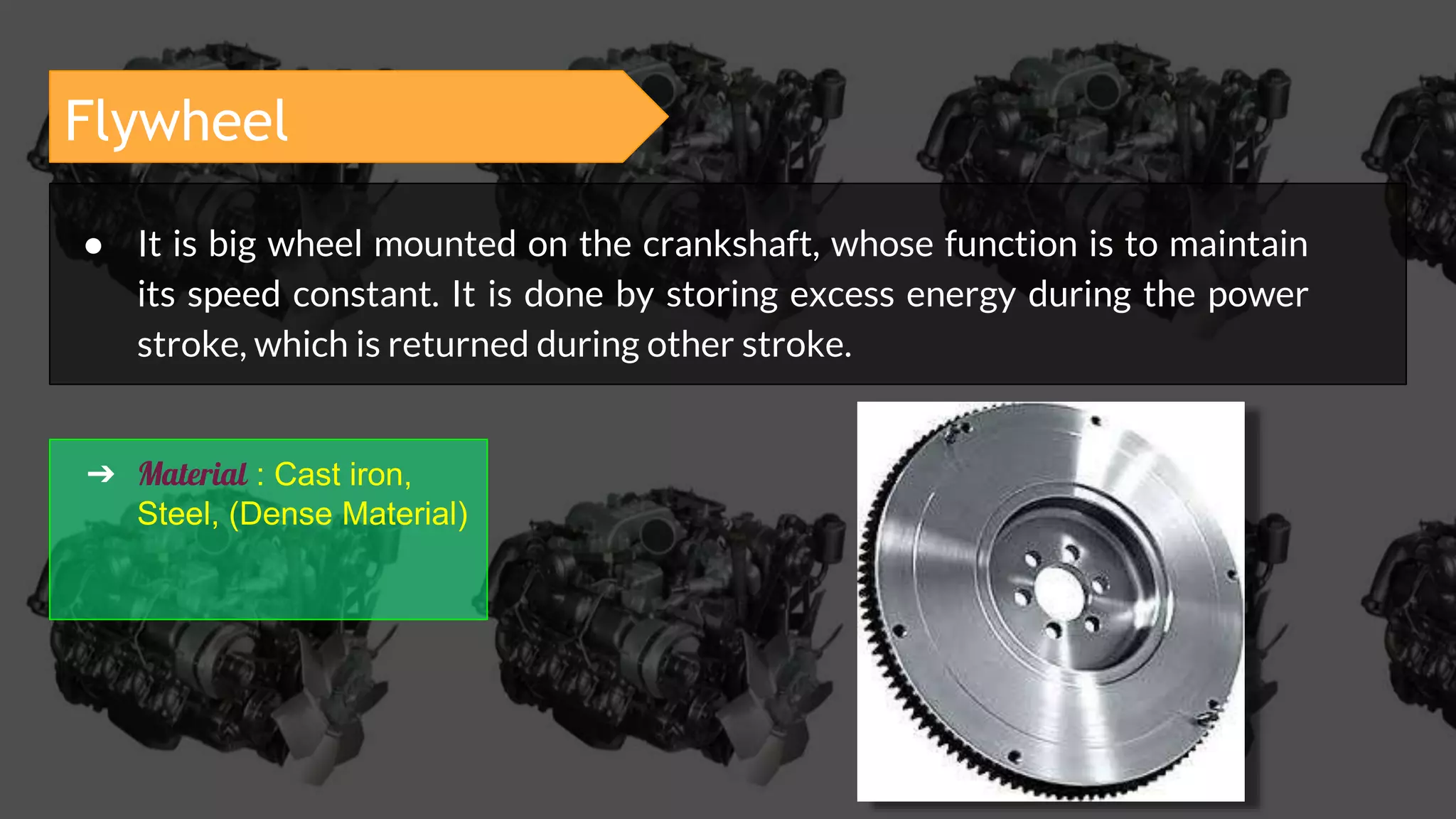

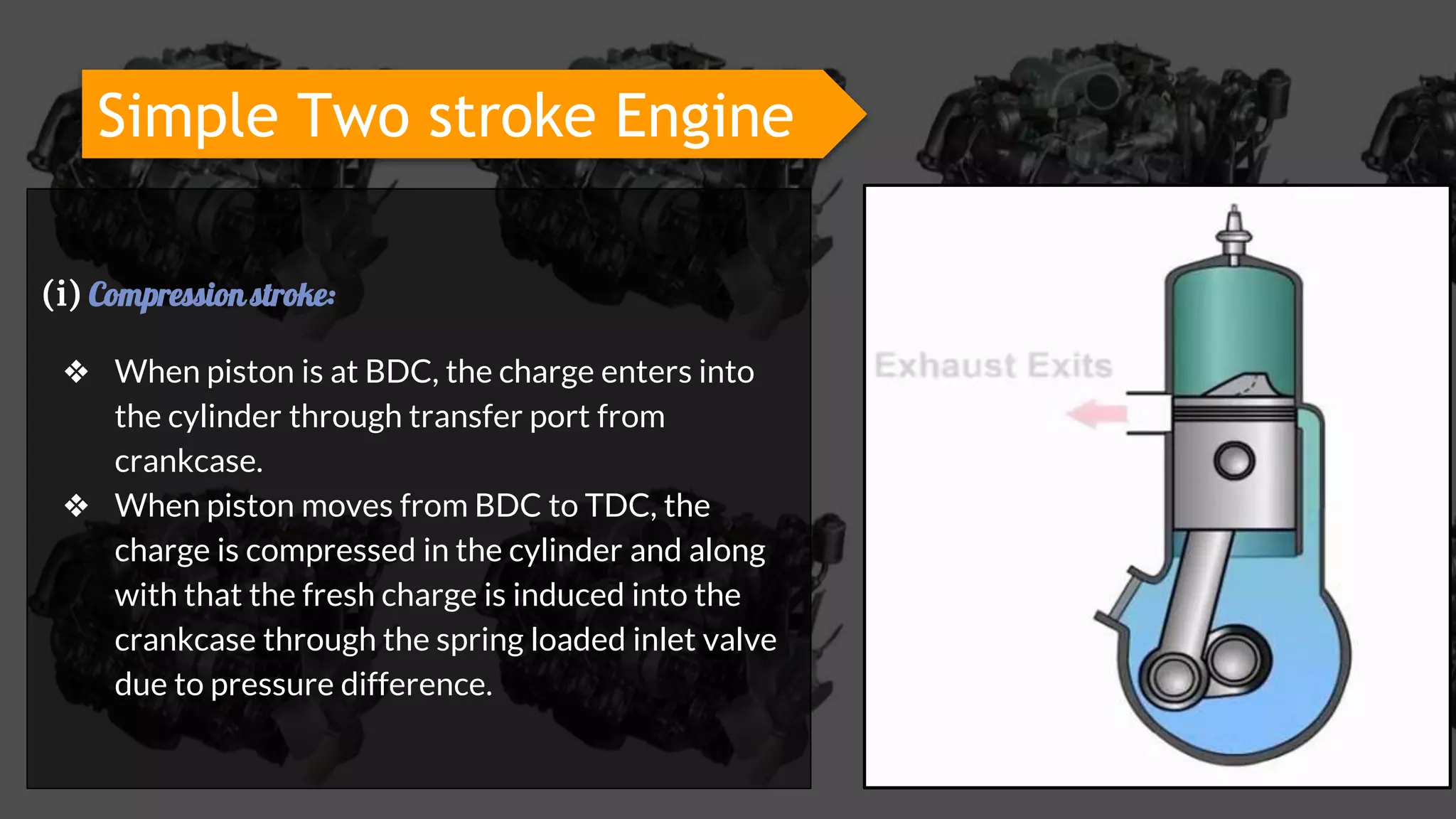

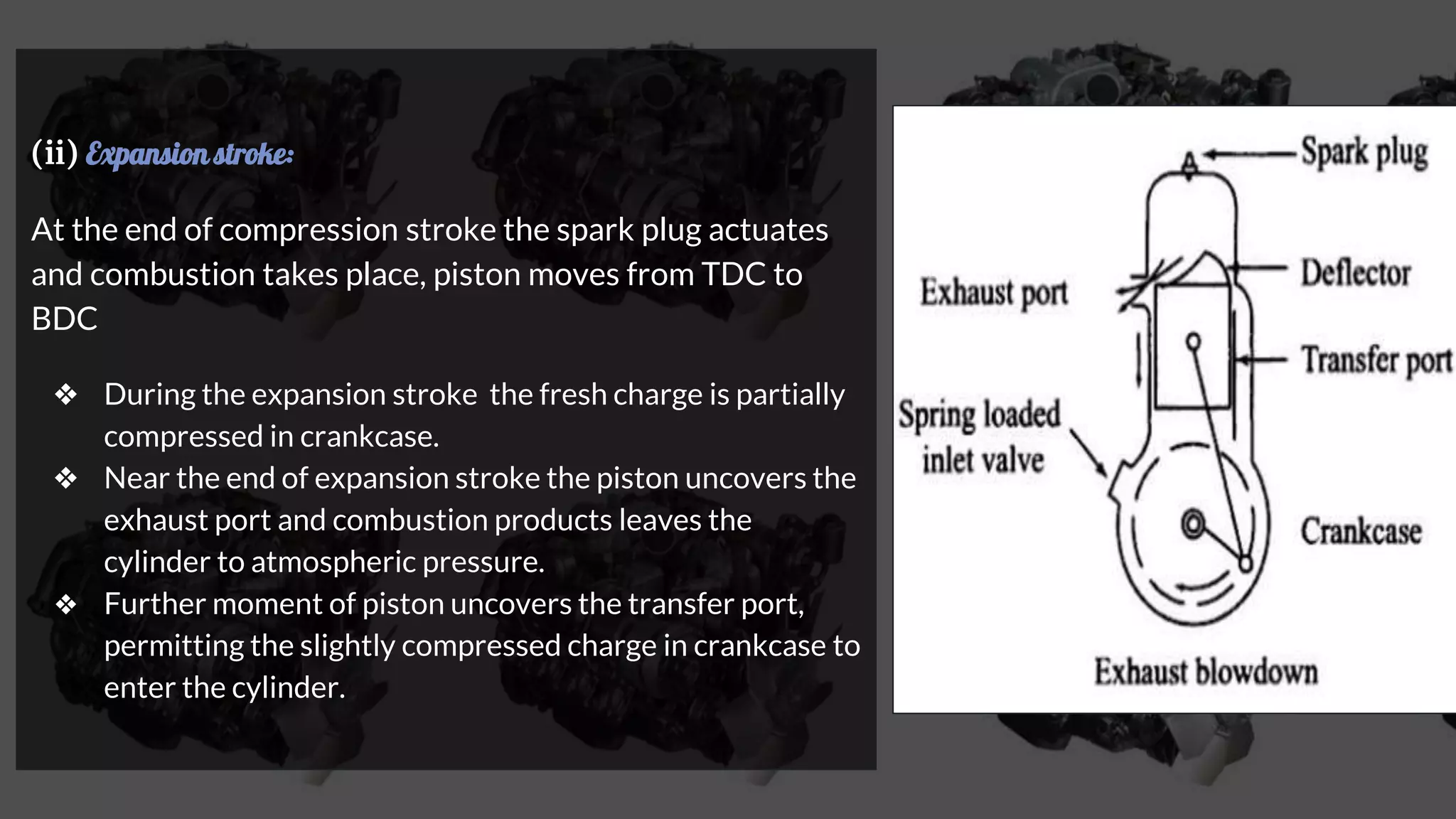

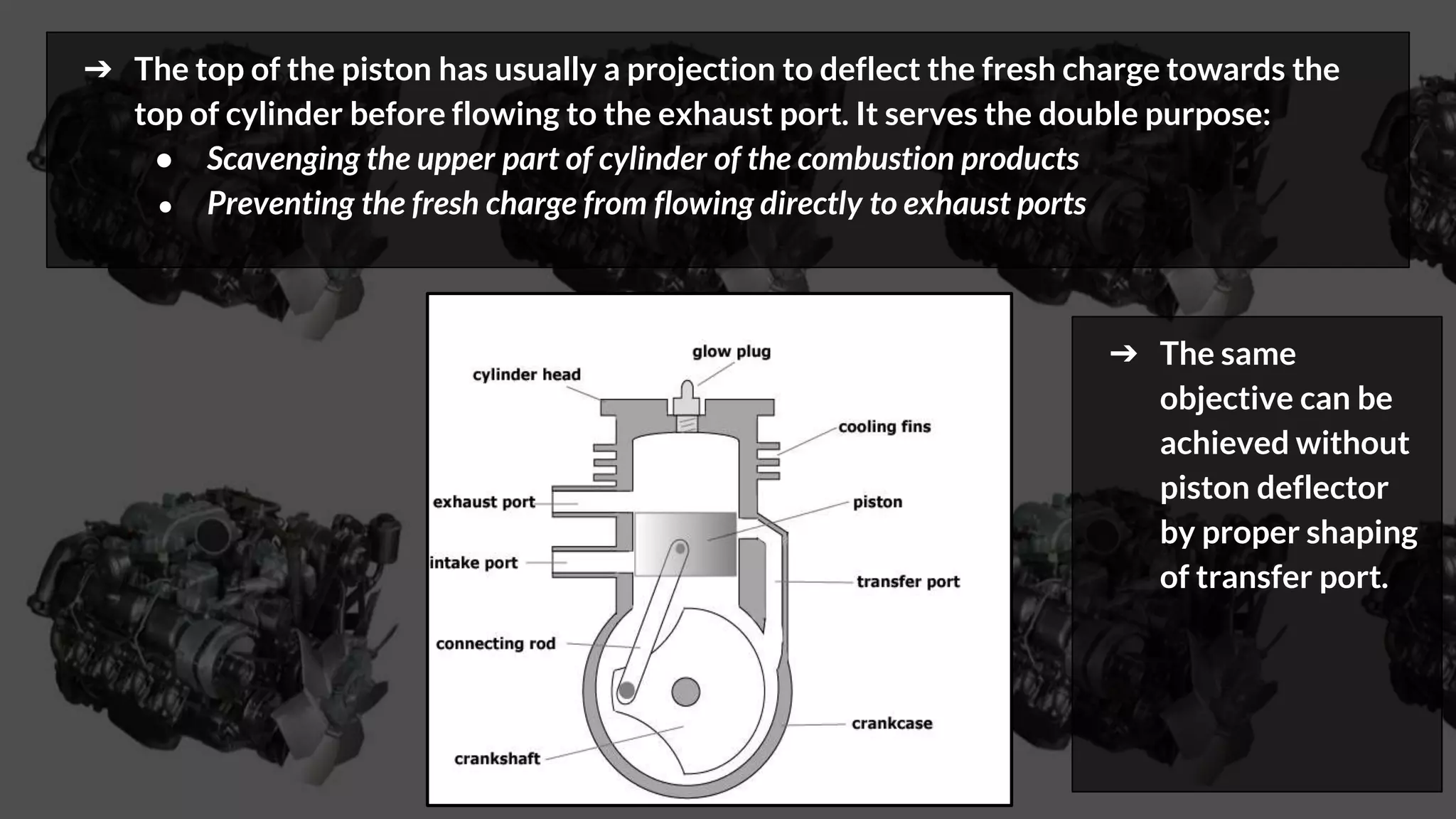

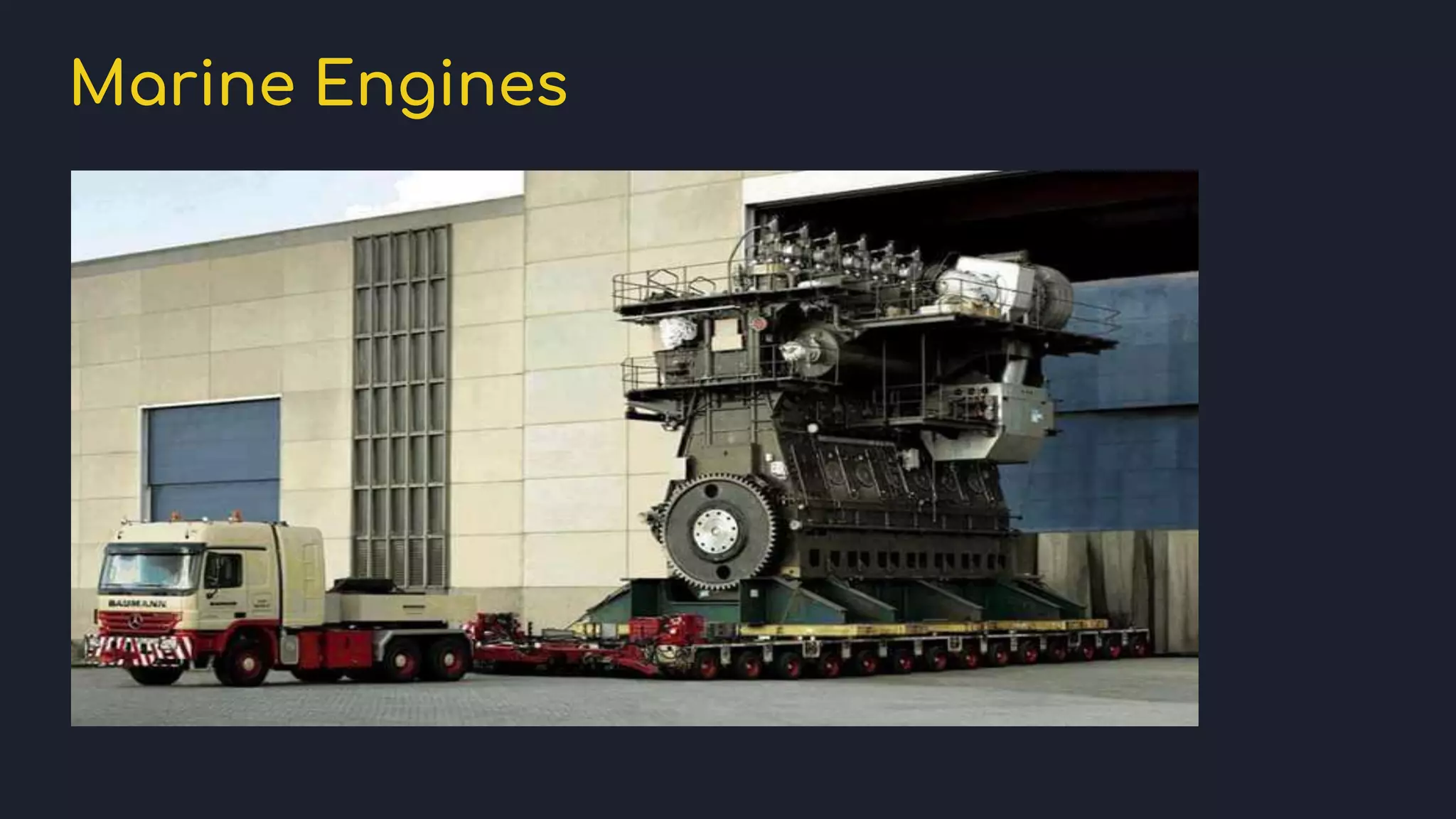

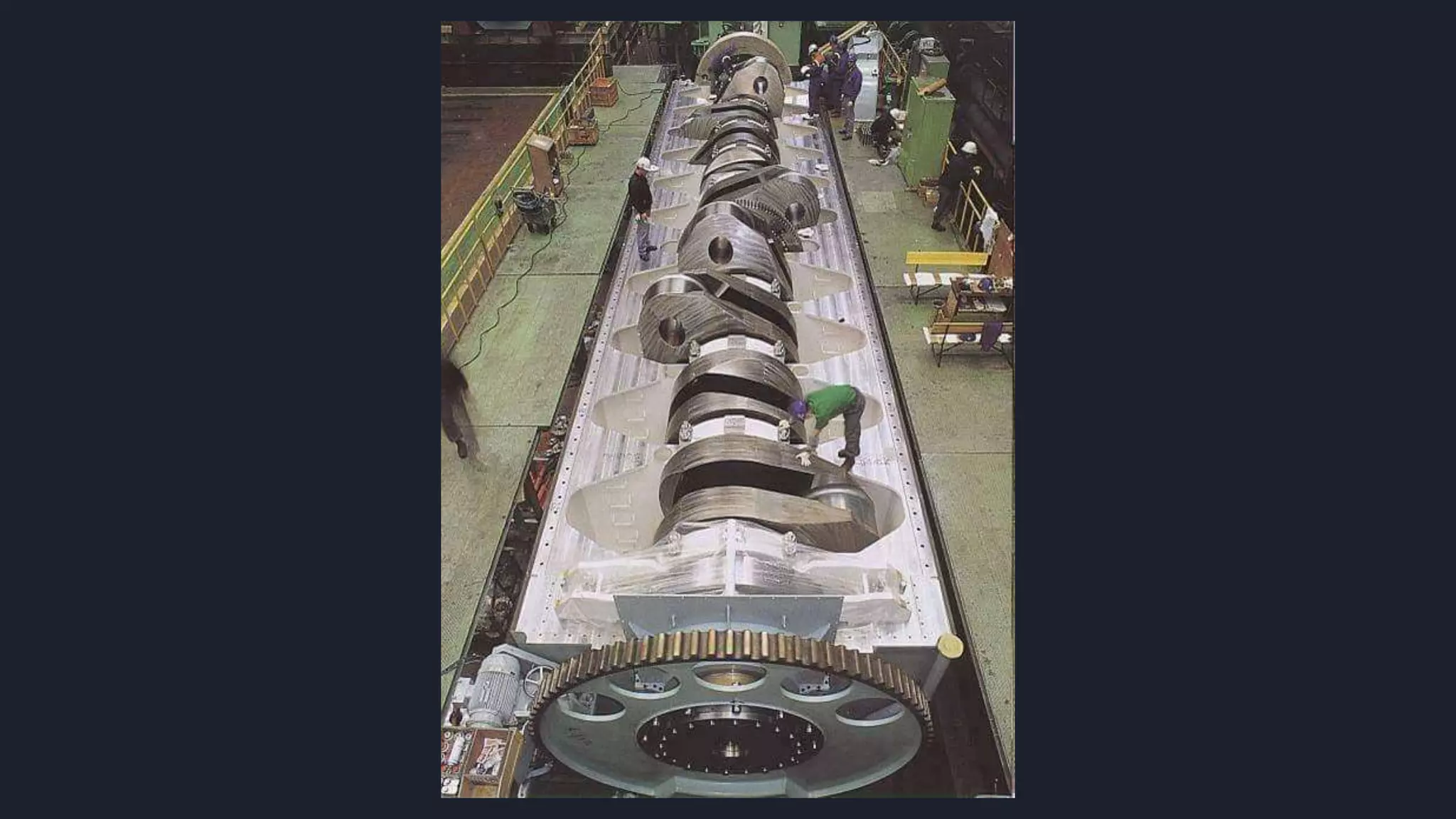

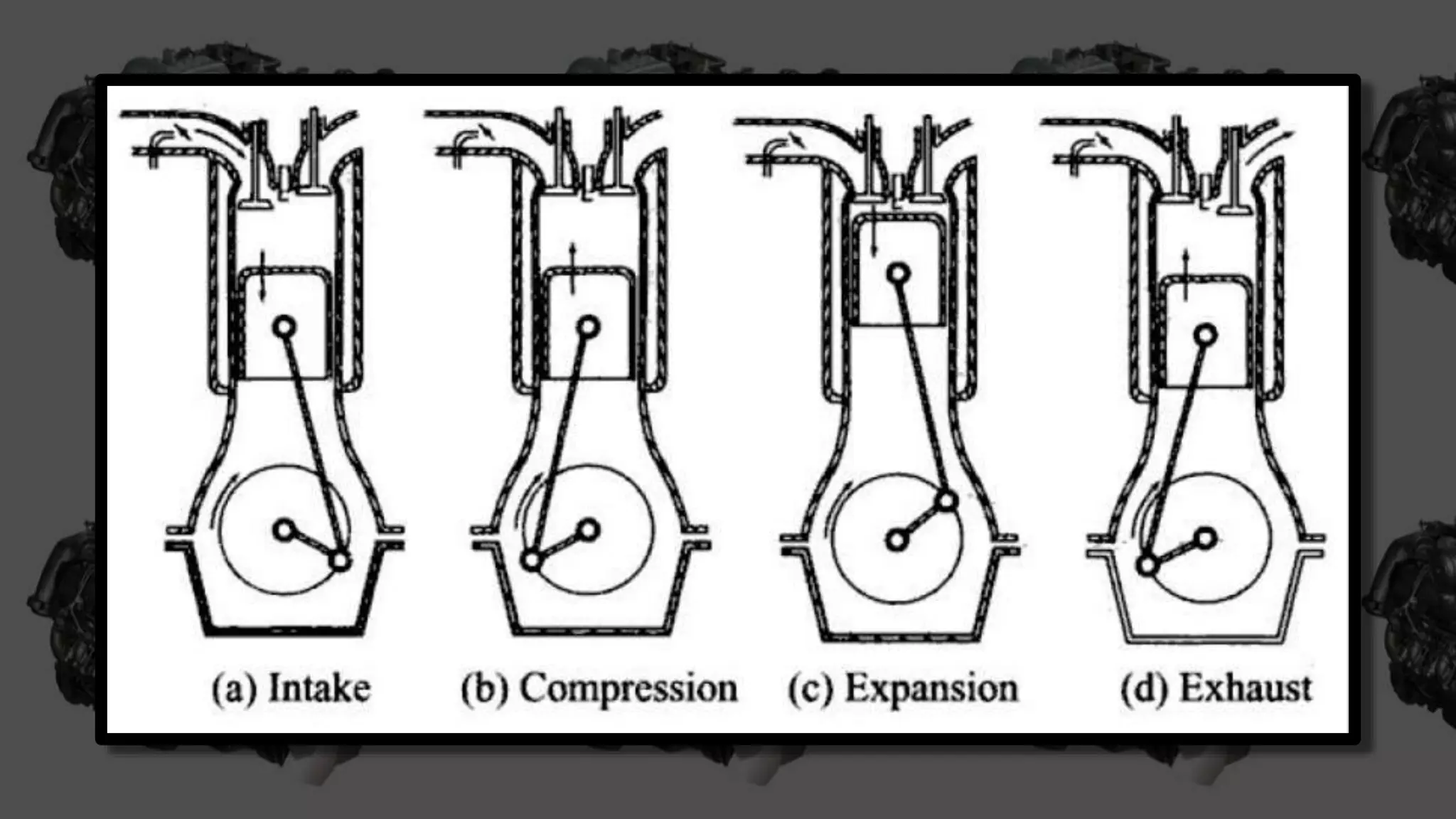

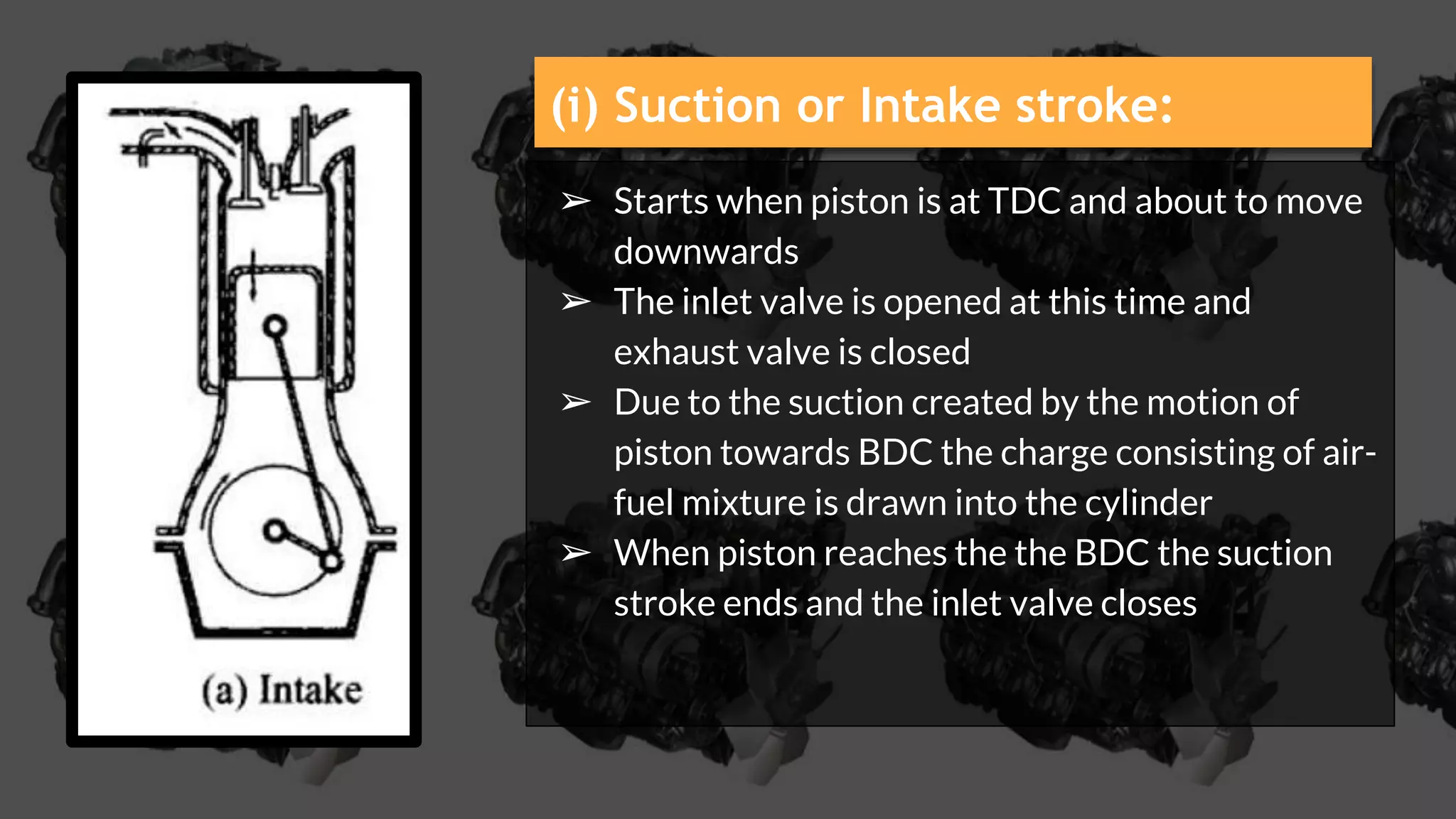

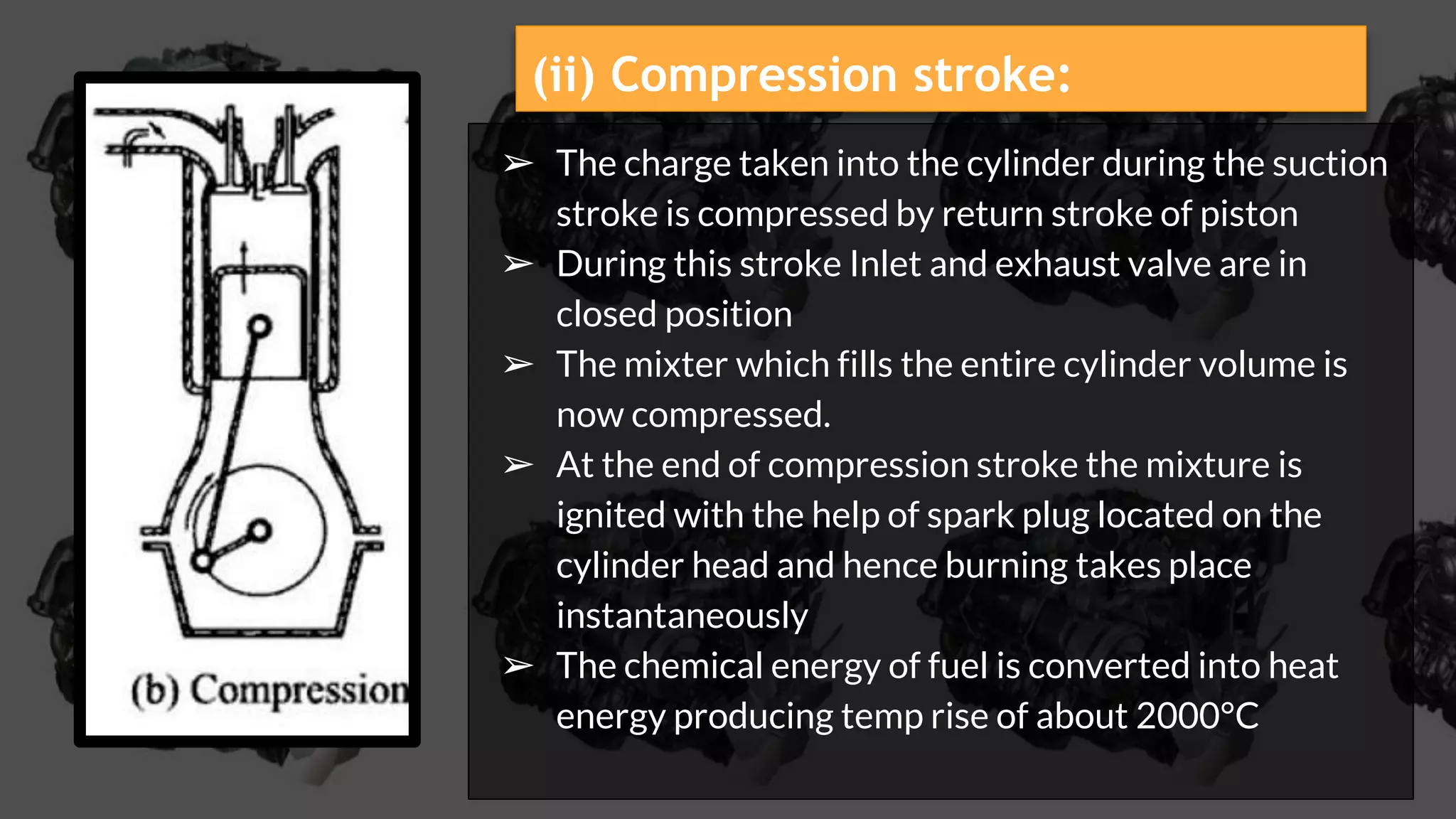

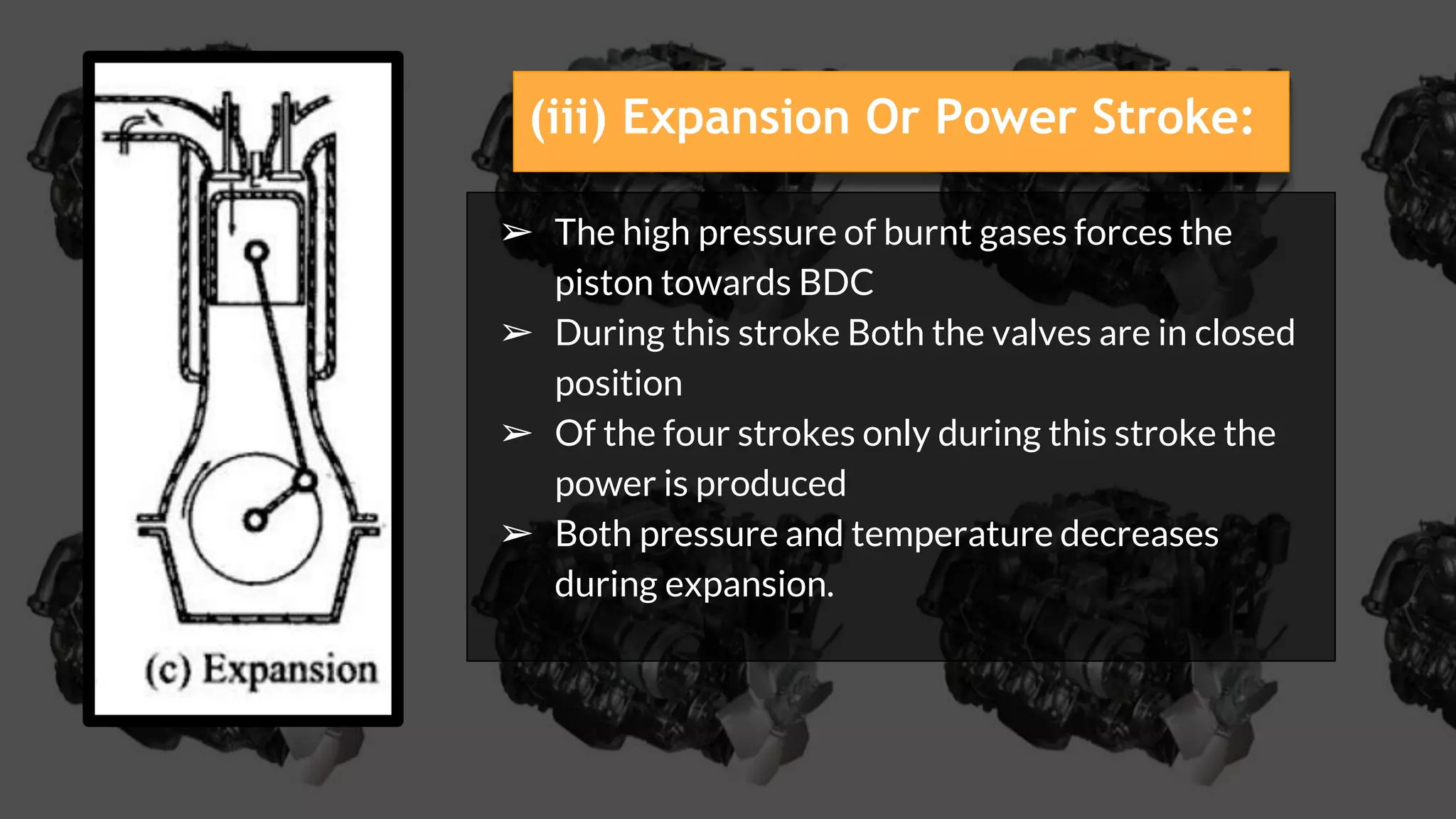

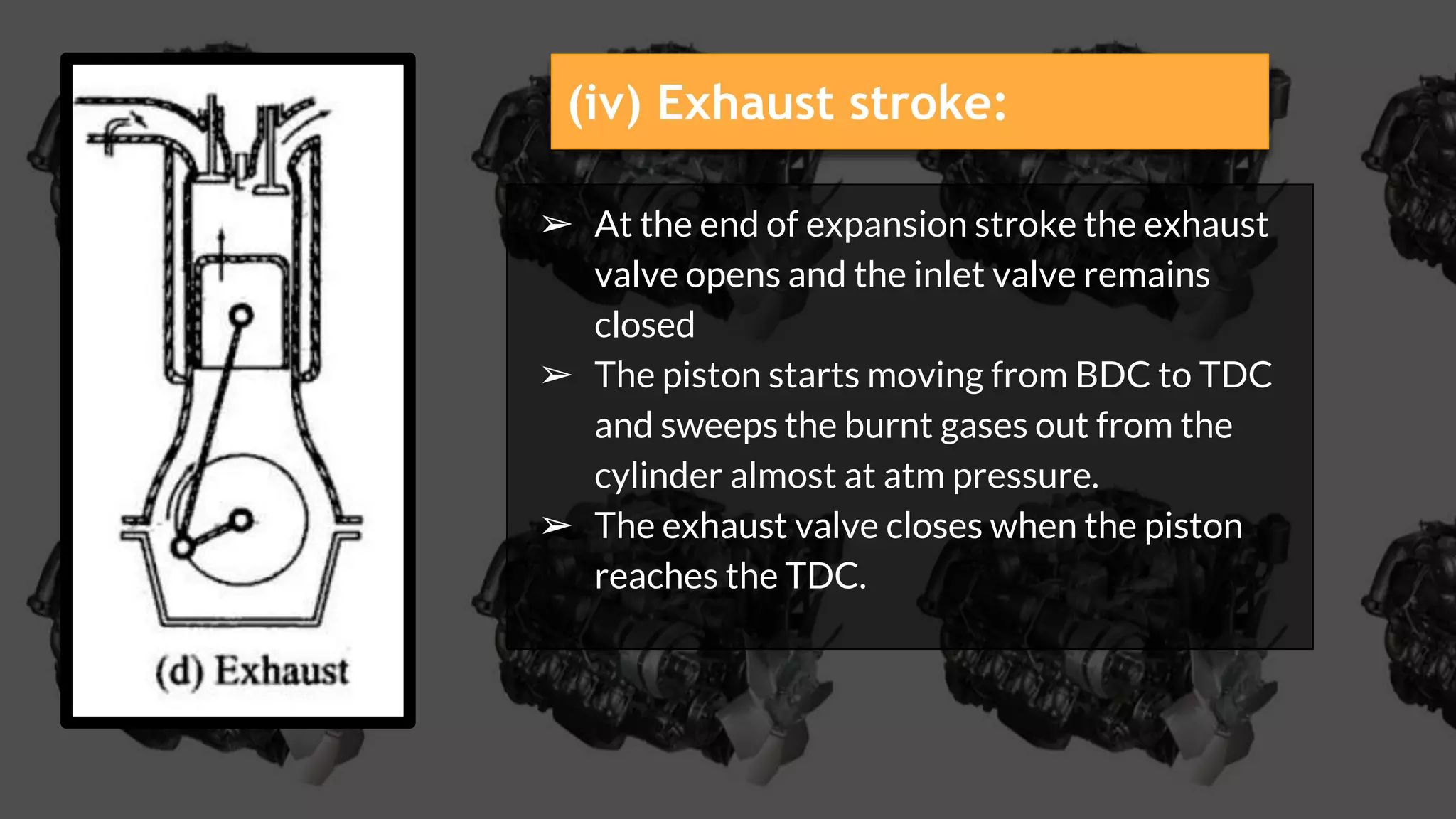

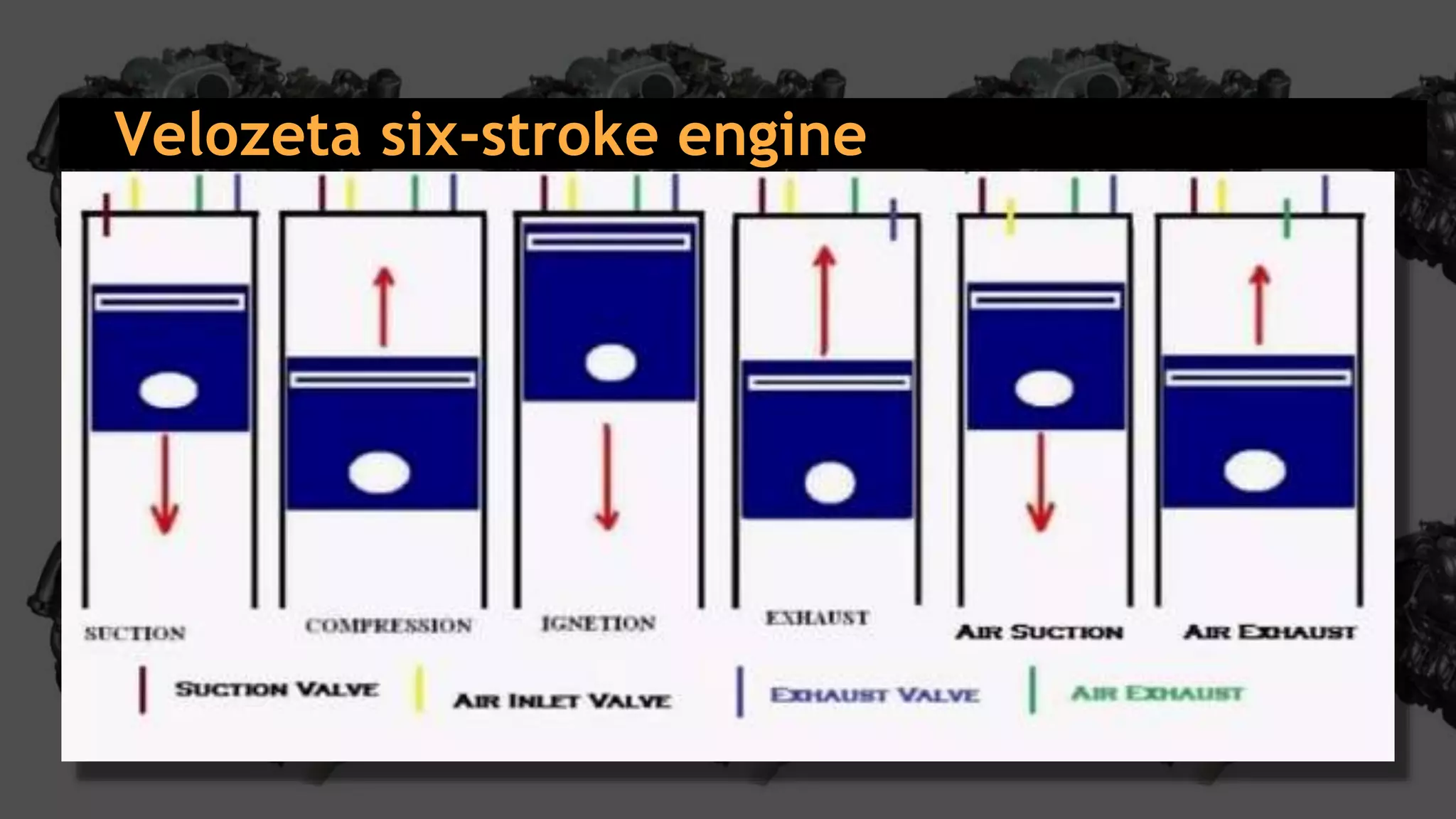

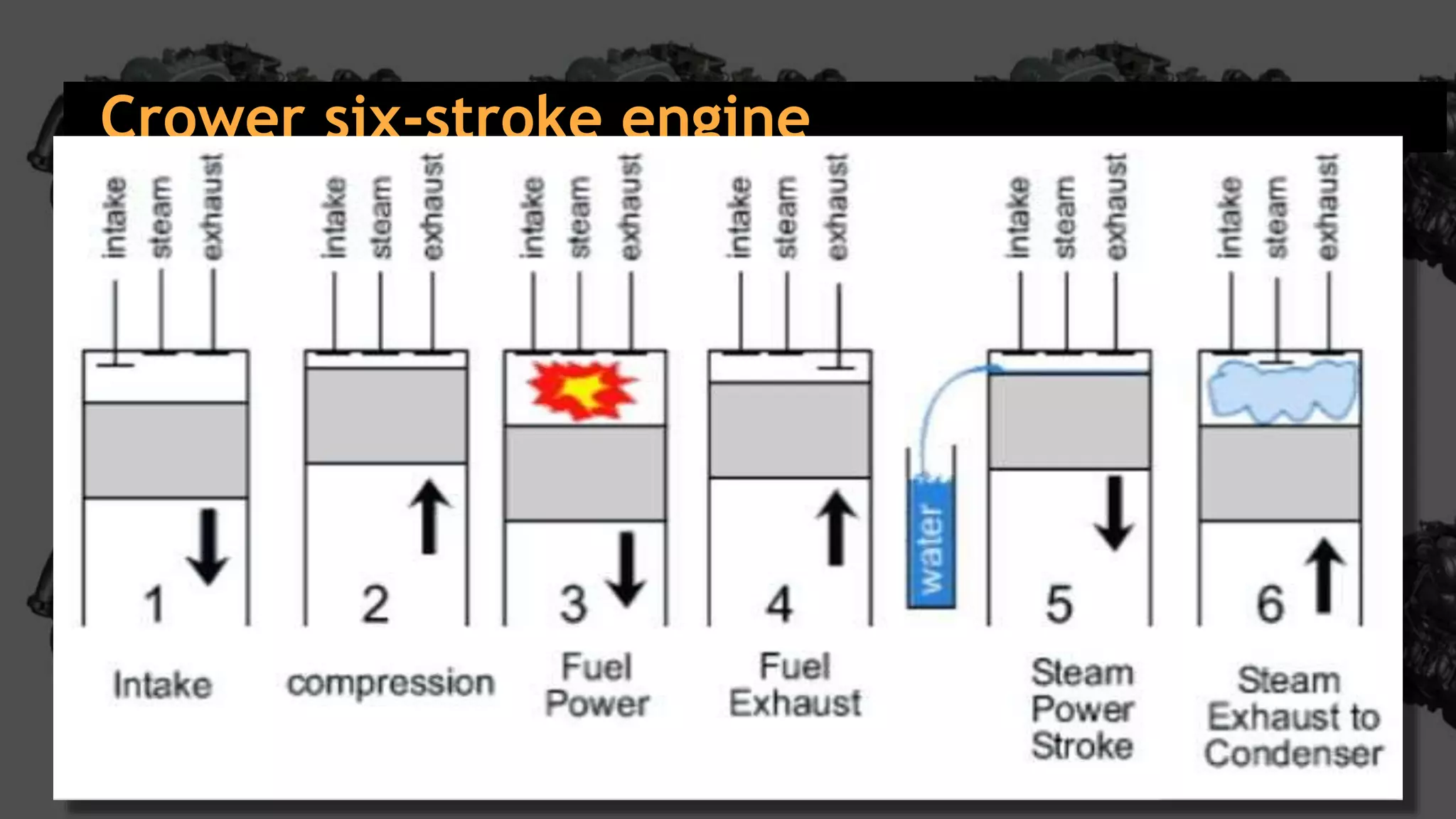

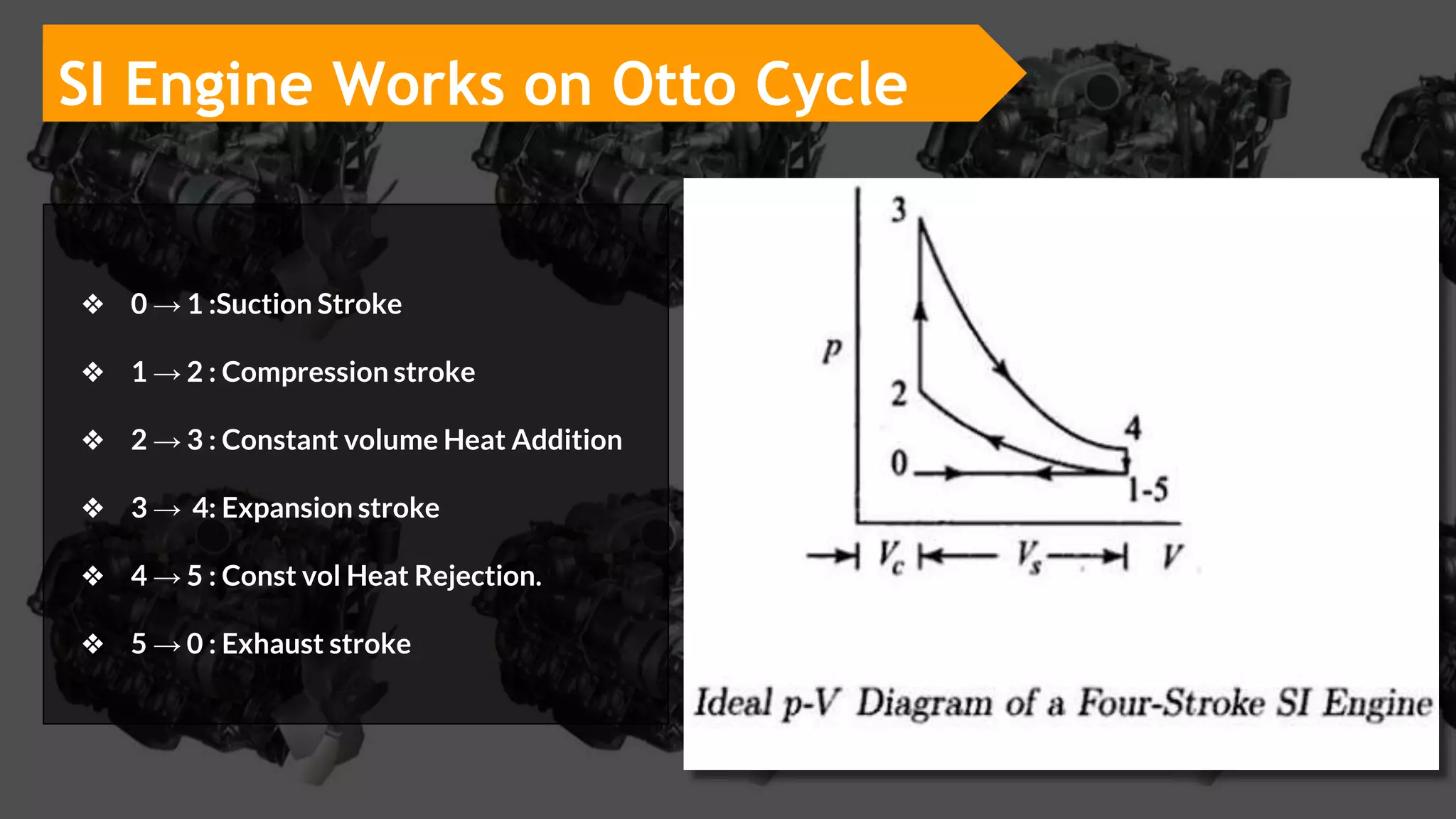

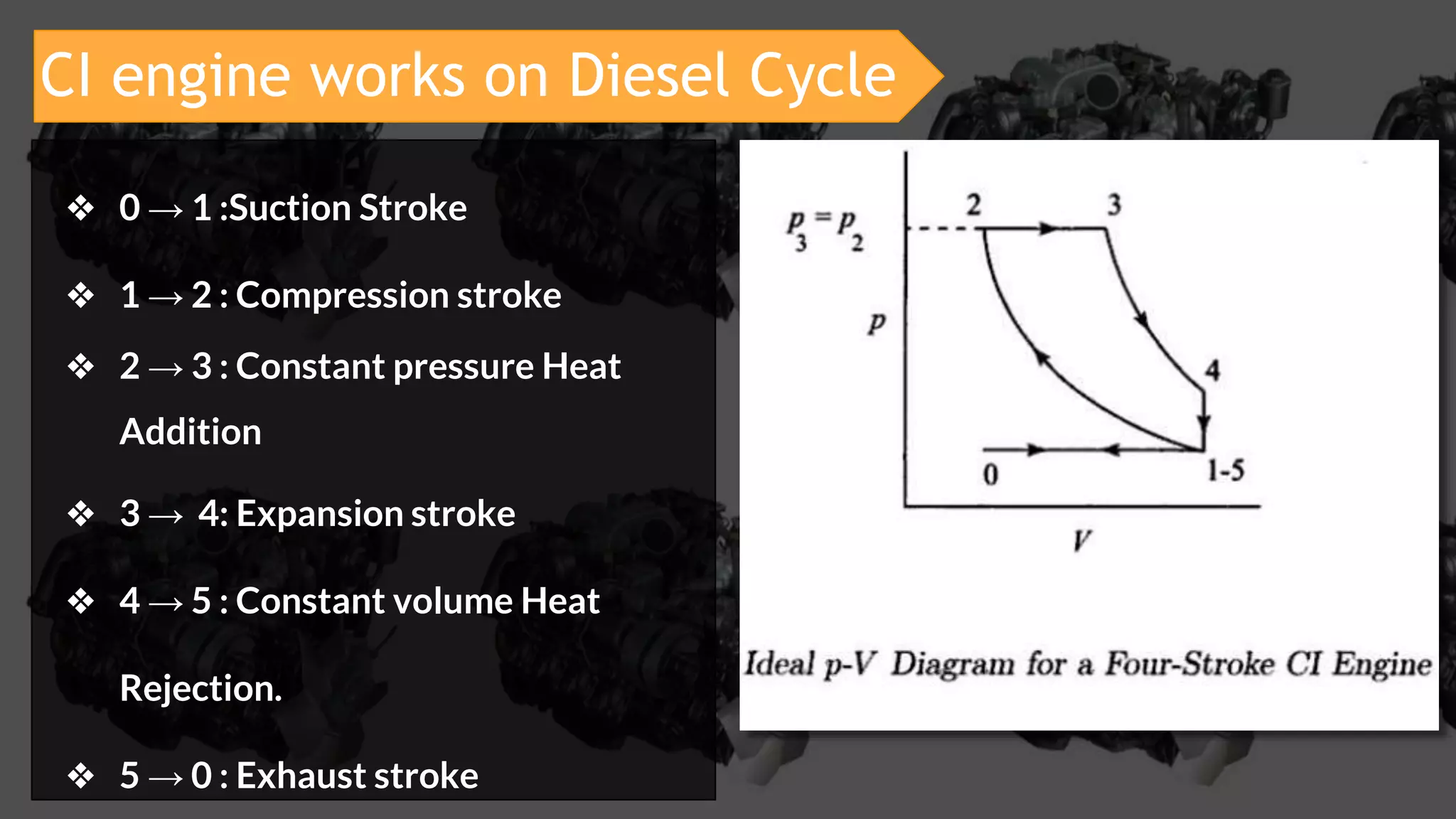

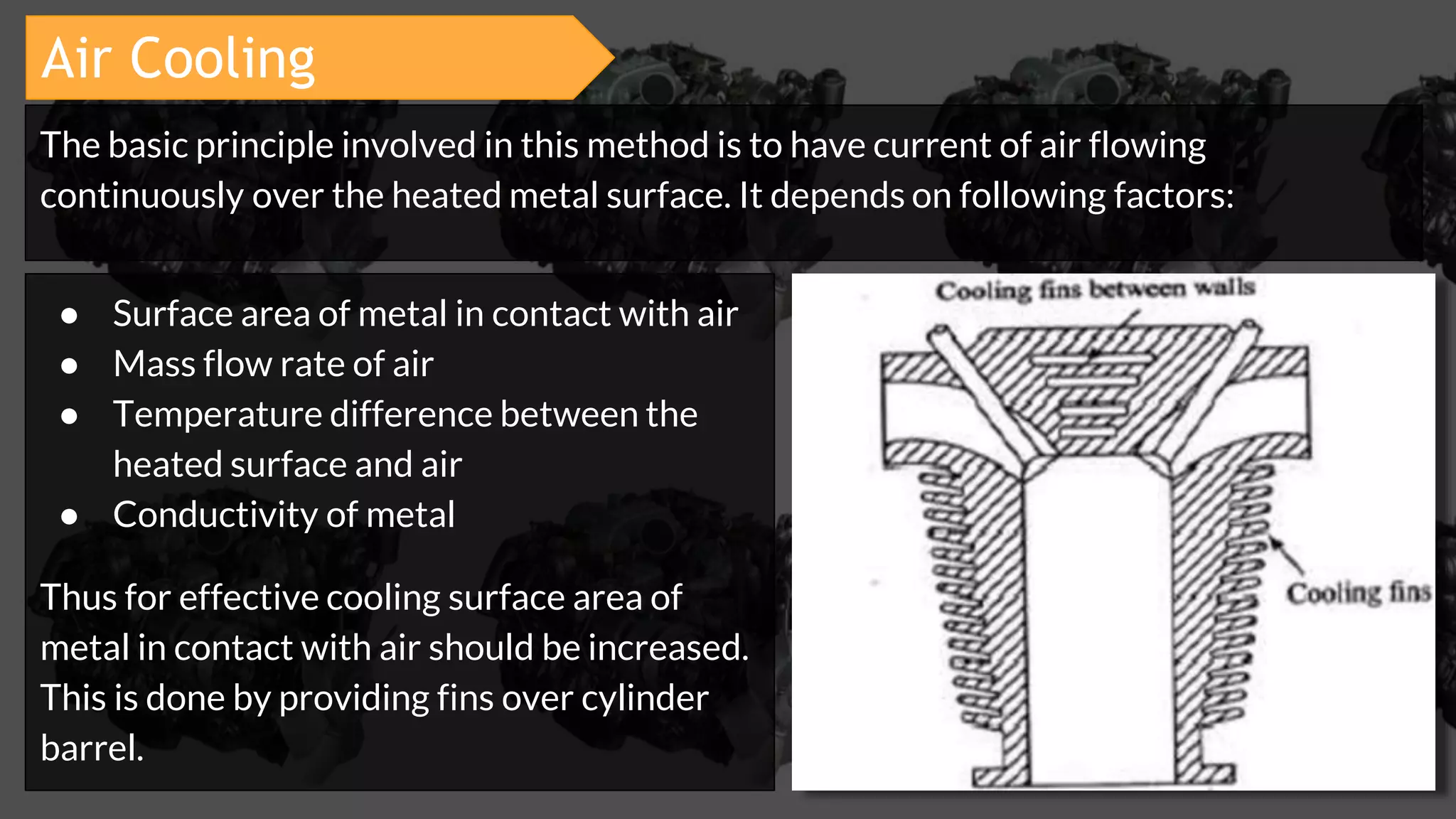

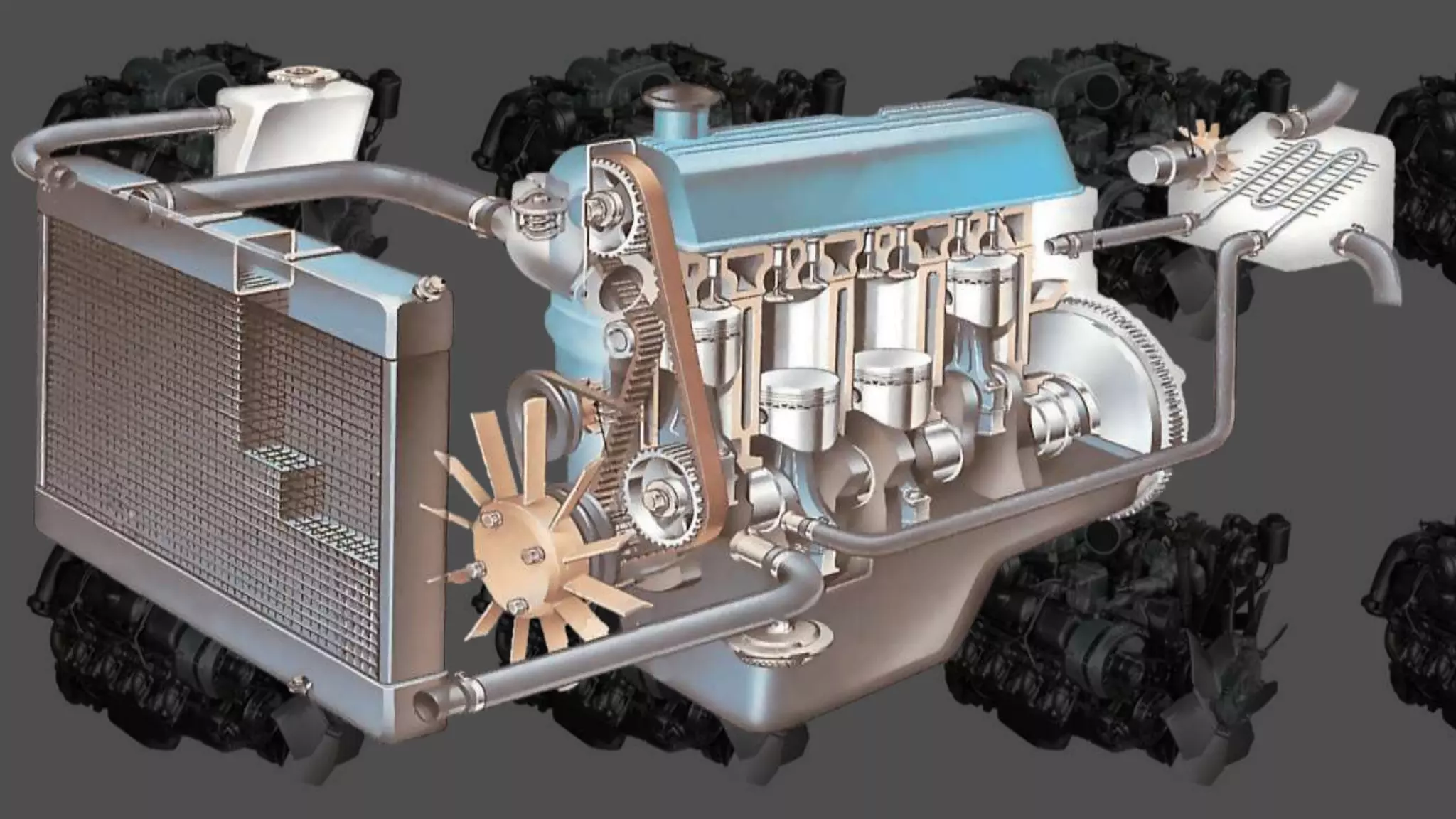

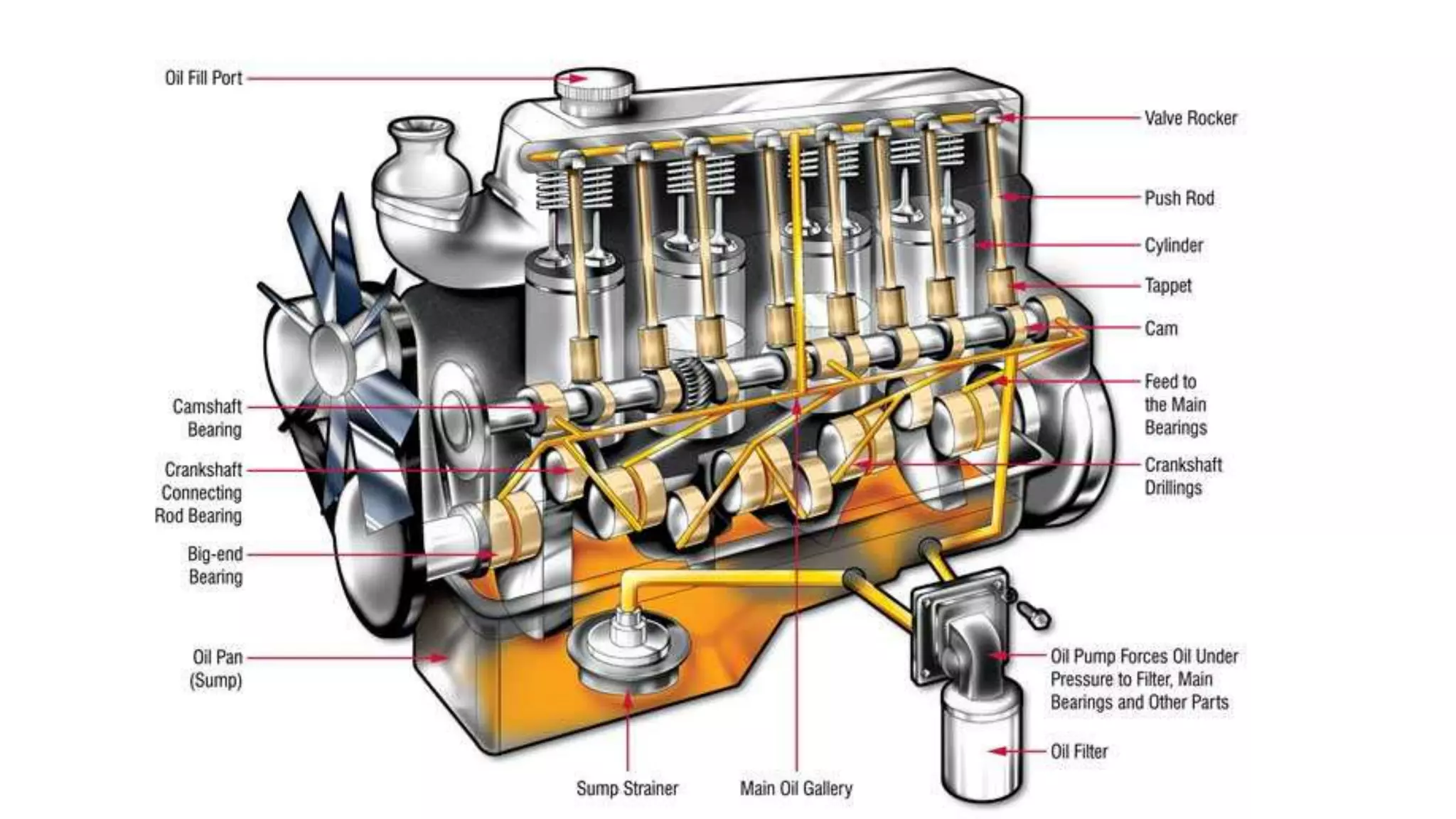

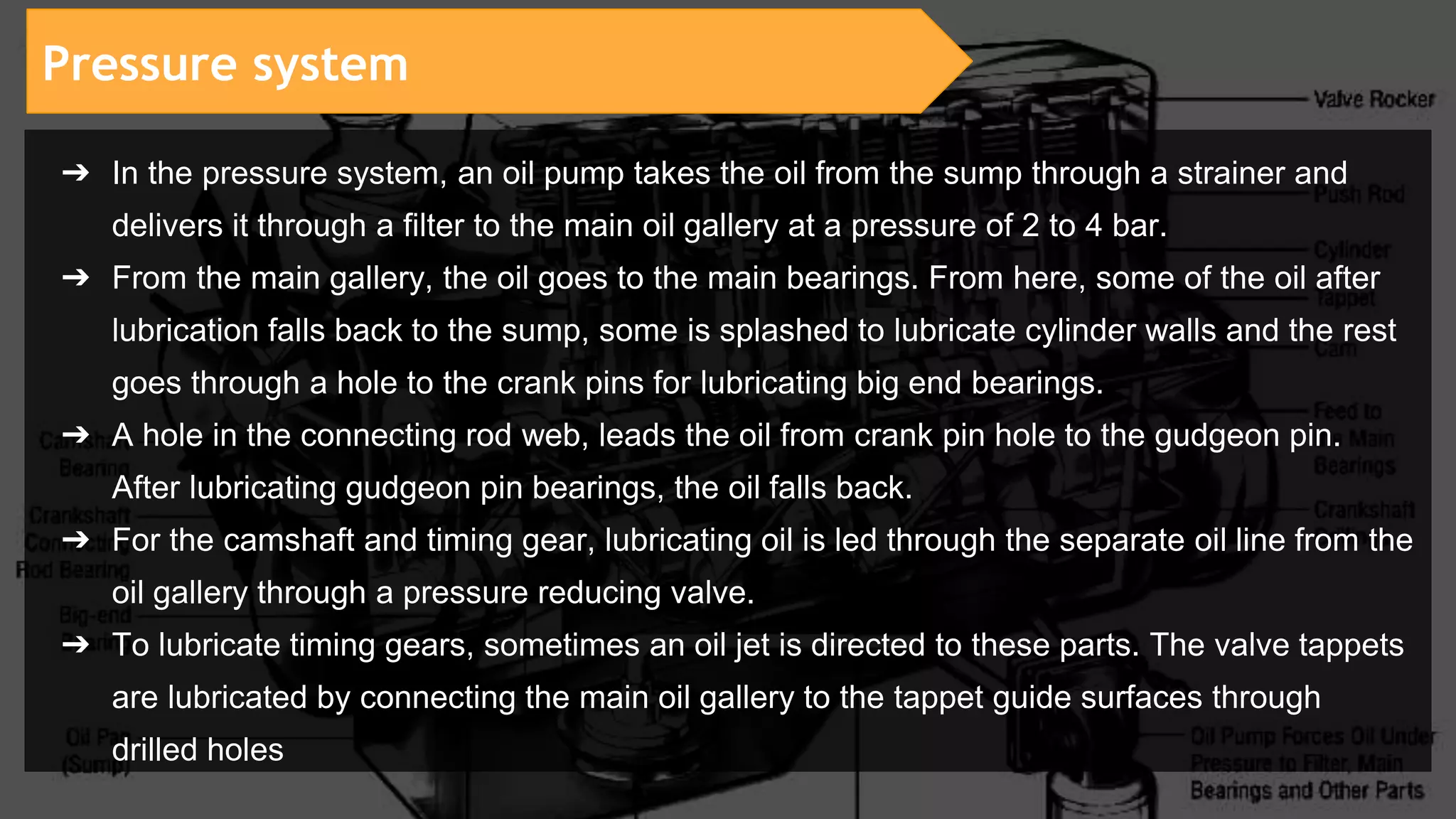

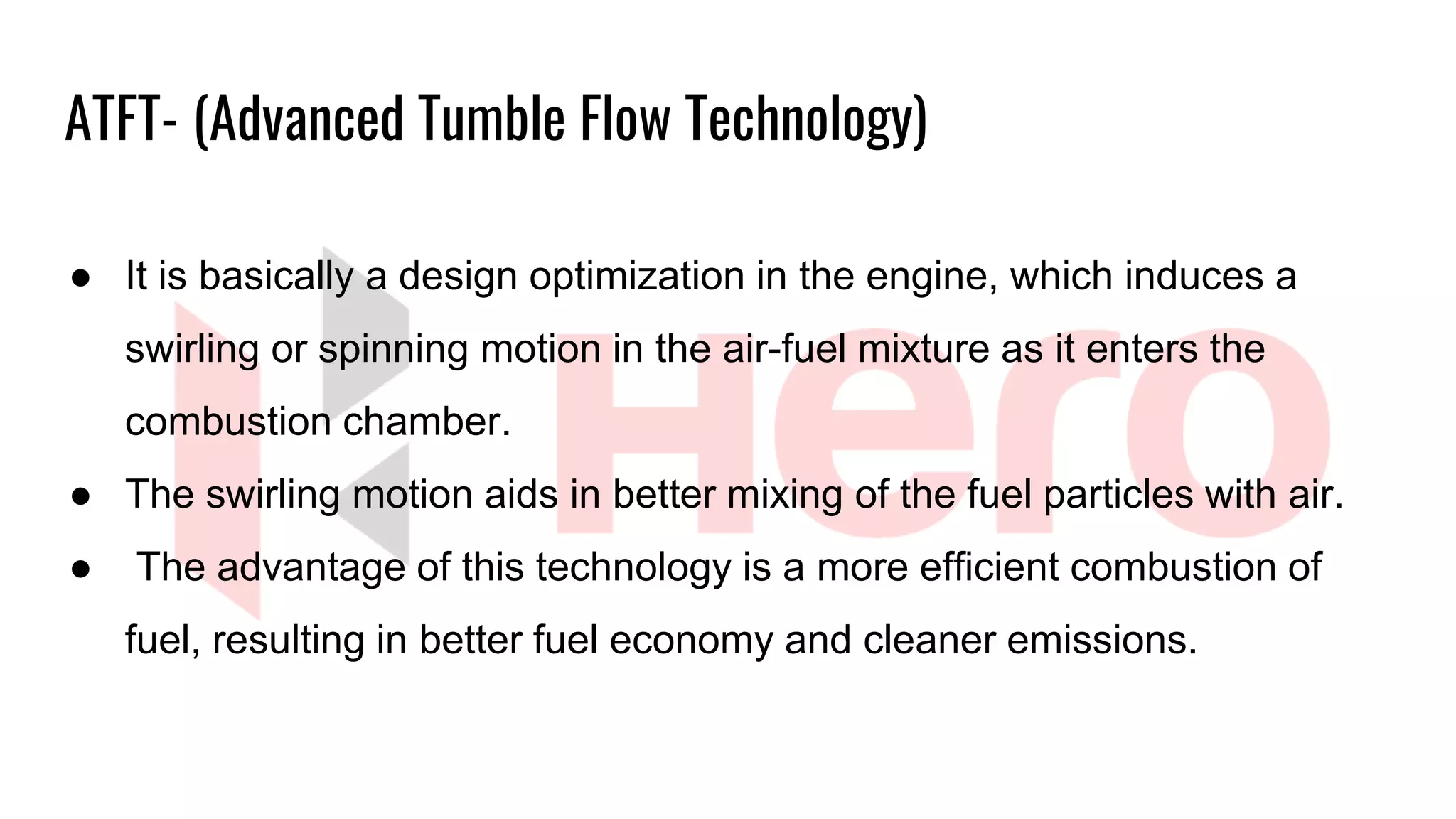

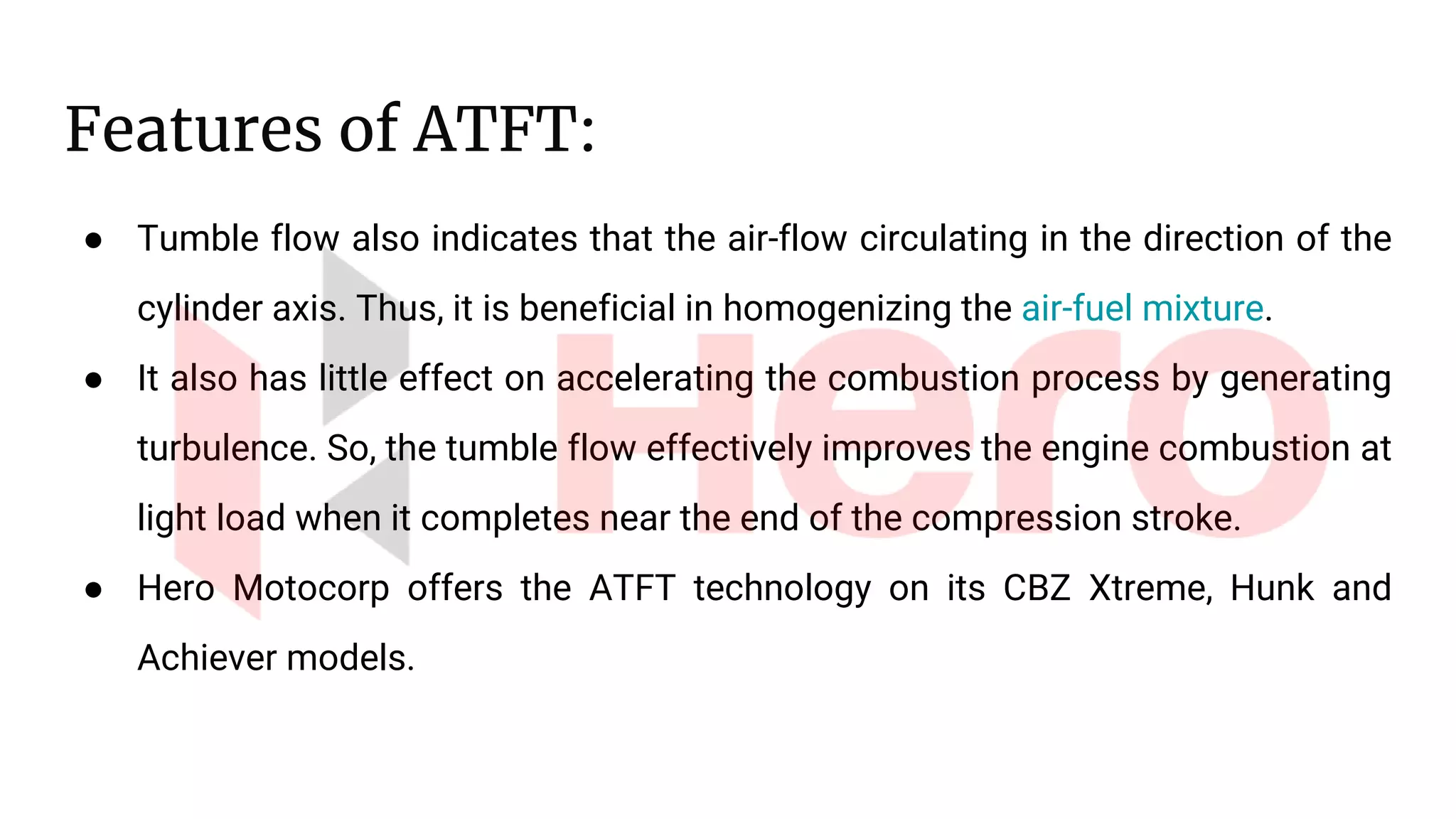

The document provides a comprehensive overview of internal combustion (IC) engines, including the differences between external and internal engines, their components, and operational principles. It details various types of IC engines, such as two-stroke, four-stroke, and six-stroke engines, explaining their operating cycles and efficiencies, as well as applications. Additionally, it covers the specifics of spark ignition (SI) and compression ignition (CI) engines and their corresponding features and cooling systems.