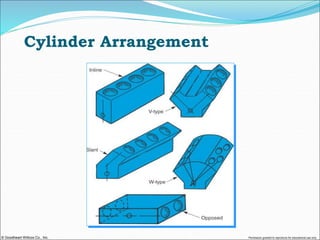

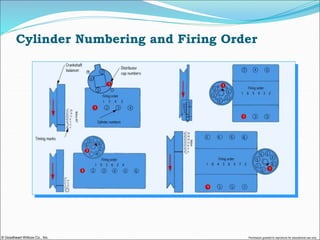

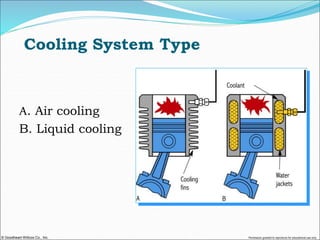

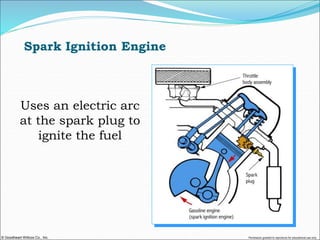

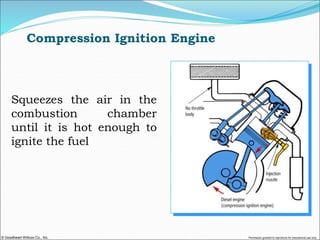

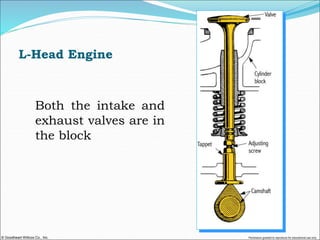

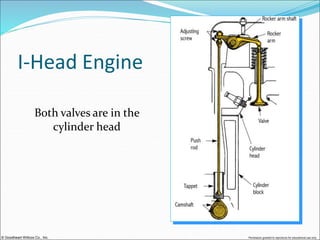

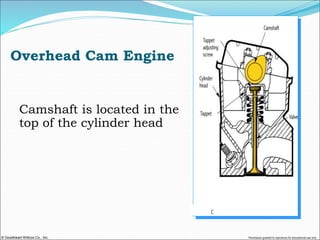

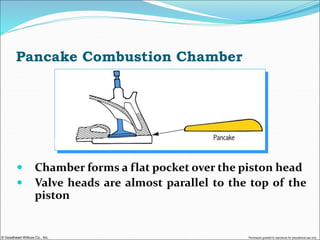

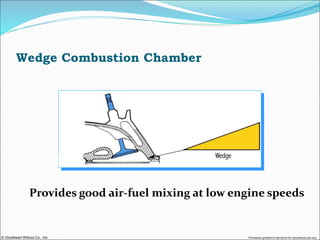

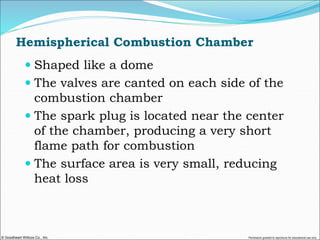

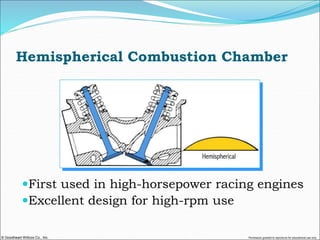

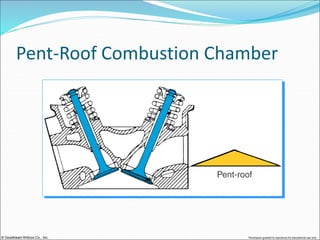

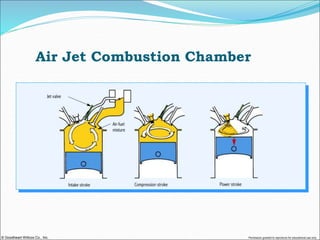

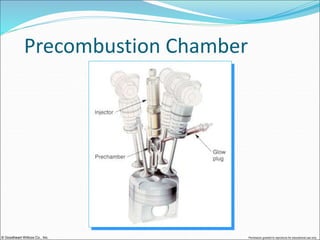

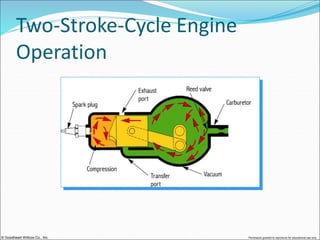

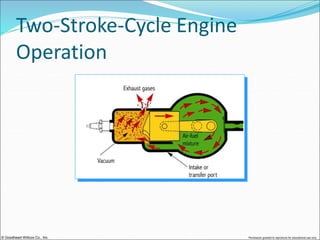

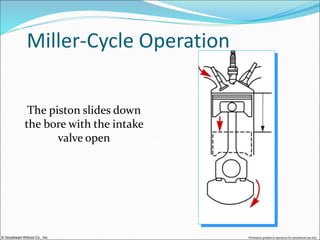

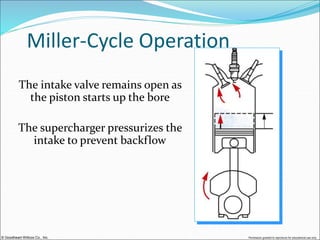

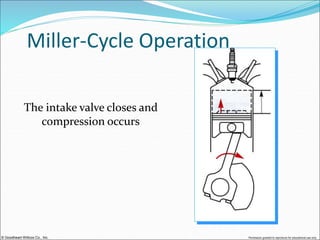

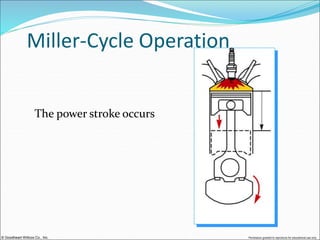

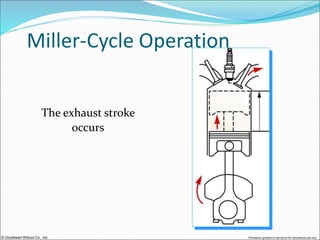

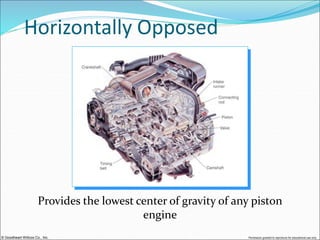

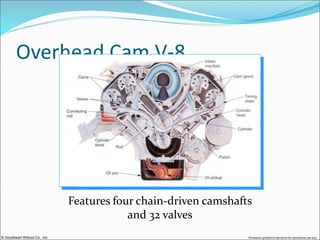

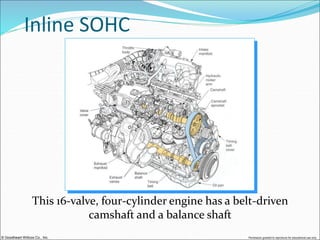

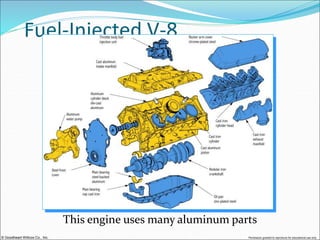

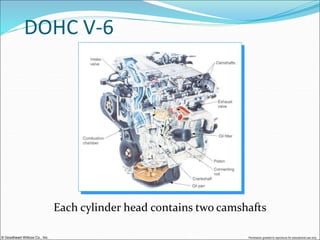

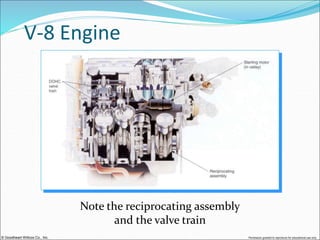

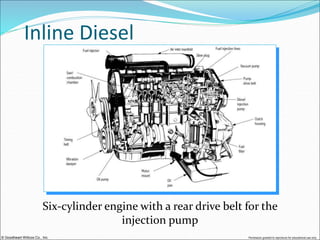

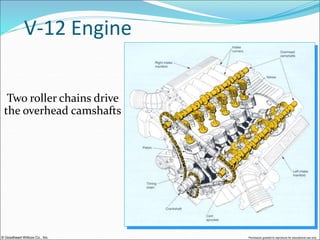

The document discusses various ways that engines can be classified and categorized. It identifies key specifications used to classify engines such as the cylinder arrangement, number of cylinders, cooling system type, valve and camshaft locations, combustion chamber design, fuel type, ignition type, and more. Common engine types are described based on these classifications, including differences in their operation.