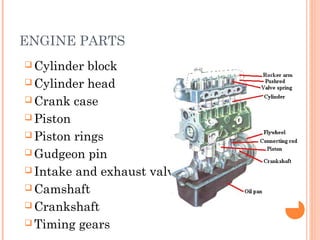

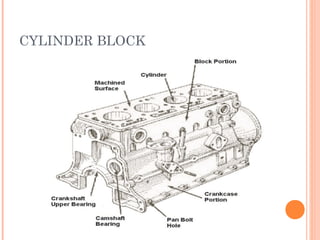

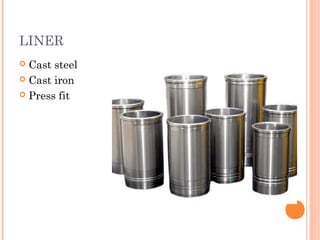

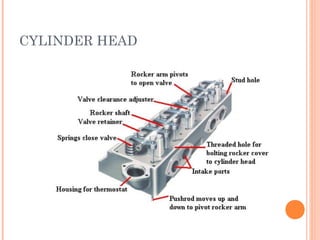

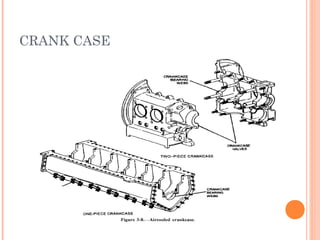

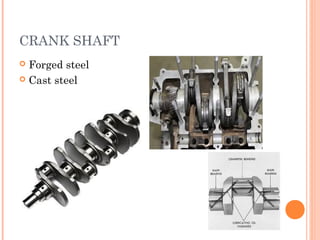

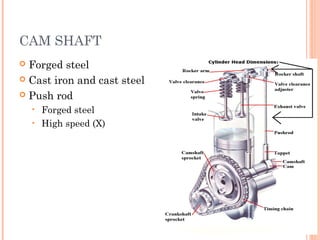

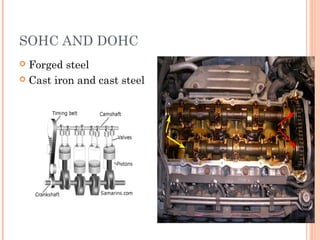

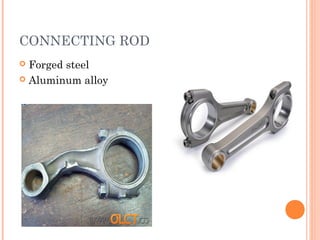

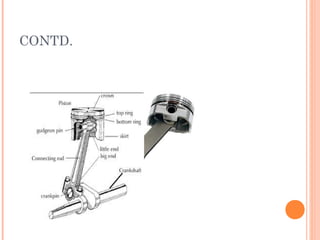

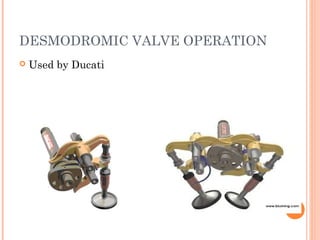

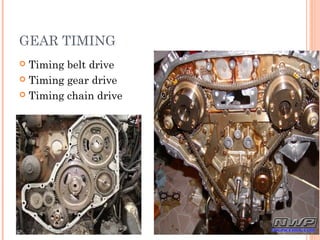

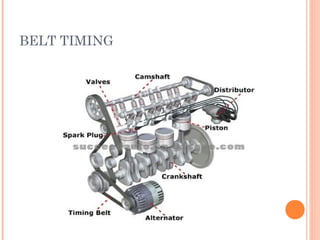

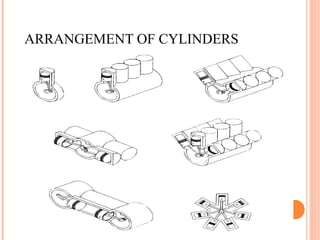

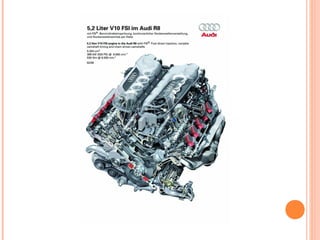

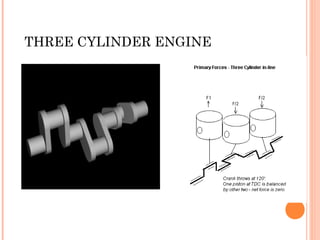

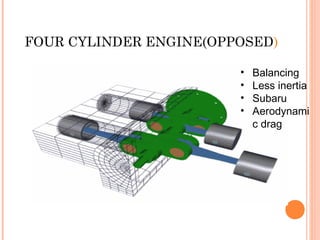

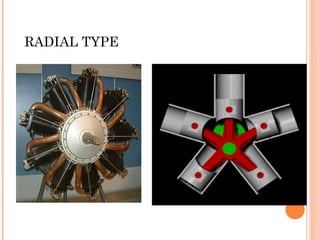

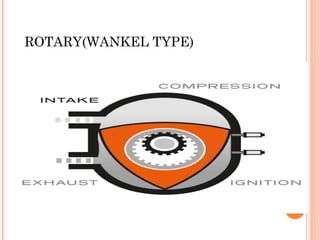

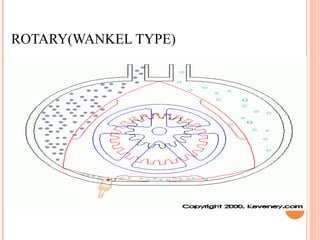

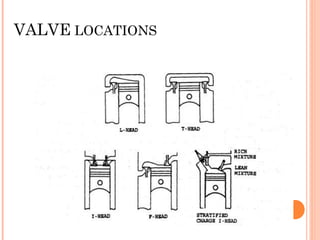

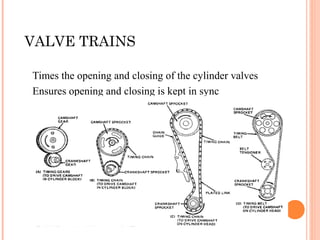

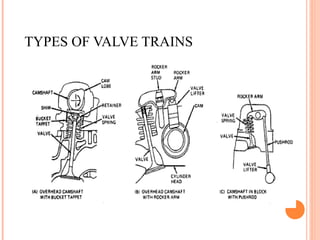

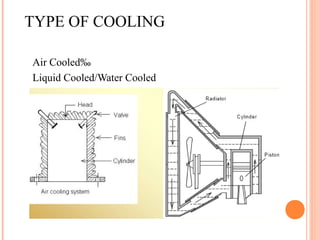

The document discusses the key parts and classifications of internal combustion engines. It describes the major components of an engine like the cylinder block, cylinder head, pistons, crankshaft and camshaft. It then covers the different types of cylinder arrangements found in engines like inline, V-shaped, opposed, radial and rotary configurations. The document also discusses the different classifications of engines based on aspects like the number of strokes, type of fuel and ignition method, firing order, cooling type and valve train layout.