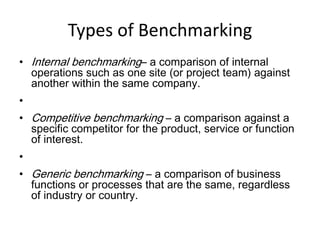

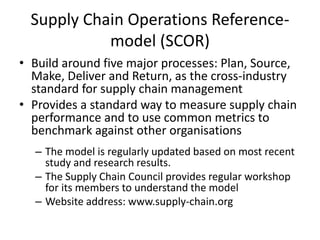

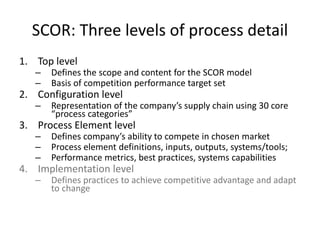

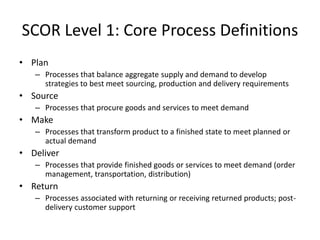

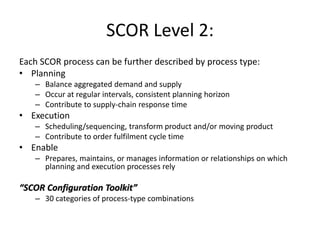

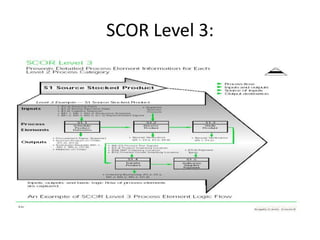

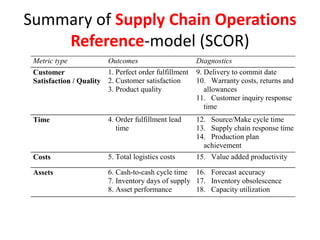

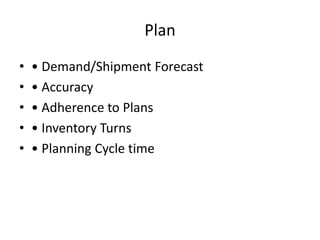

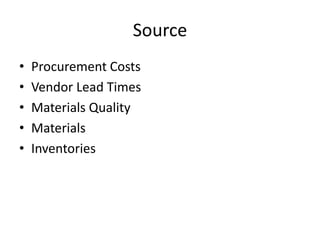

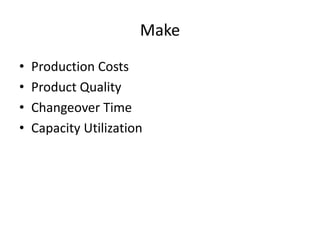

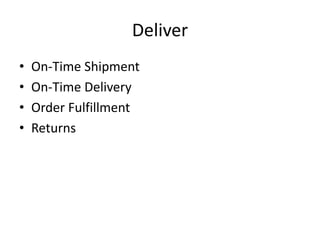

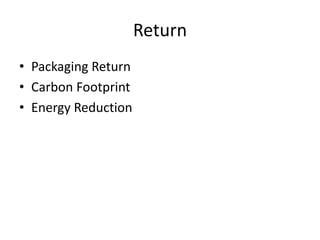

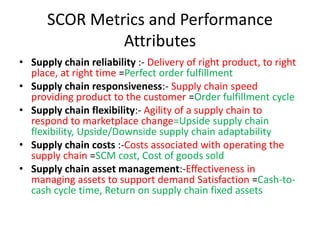

The document discusses performance measurement in supply chain management. It describes benchmarking as identifying best practices from other organizations to improve performance. The Supply Chain Operations Reference model (SCOR) is presented as a standard for measuring and benchmarking supply chain performance. SCOR defines core processes, performance attributes, and metrics across five process categories: plan, source, make, deliver, and return. Key metrics include order fulfillment, customer satisfaction, costs, inventory levels, and supply chain response time.