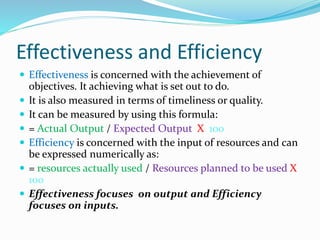

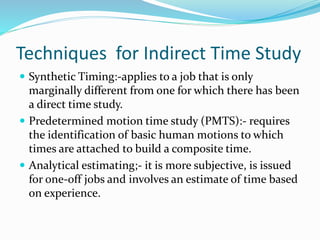

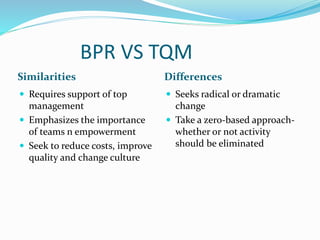

The document discusses concepts related to business productivity including effectiveness, efficiency, productivity, factors that influence productivity, causes of low productivity, and ways to raise productivity. It also covers work study techniques like method study and work measurement. Other topics include benchmarking, types of benchmarking, benefits of benchmarking, business process reengineering (BPR), similarities and differences between BPR and total quality management (TQM), advantages and criticism of BPR.