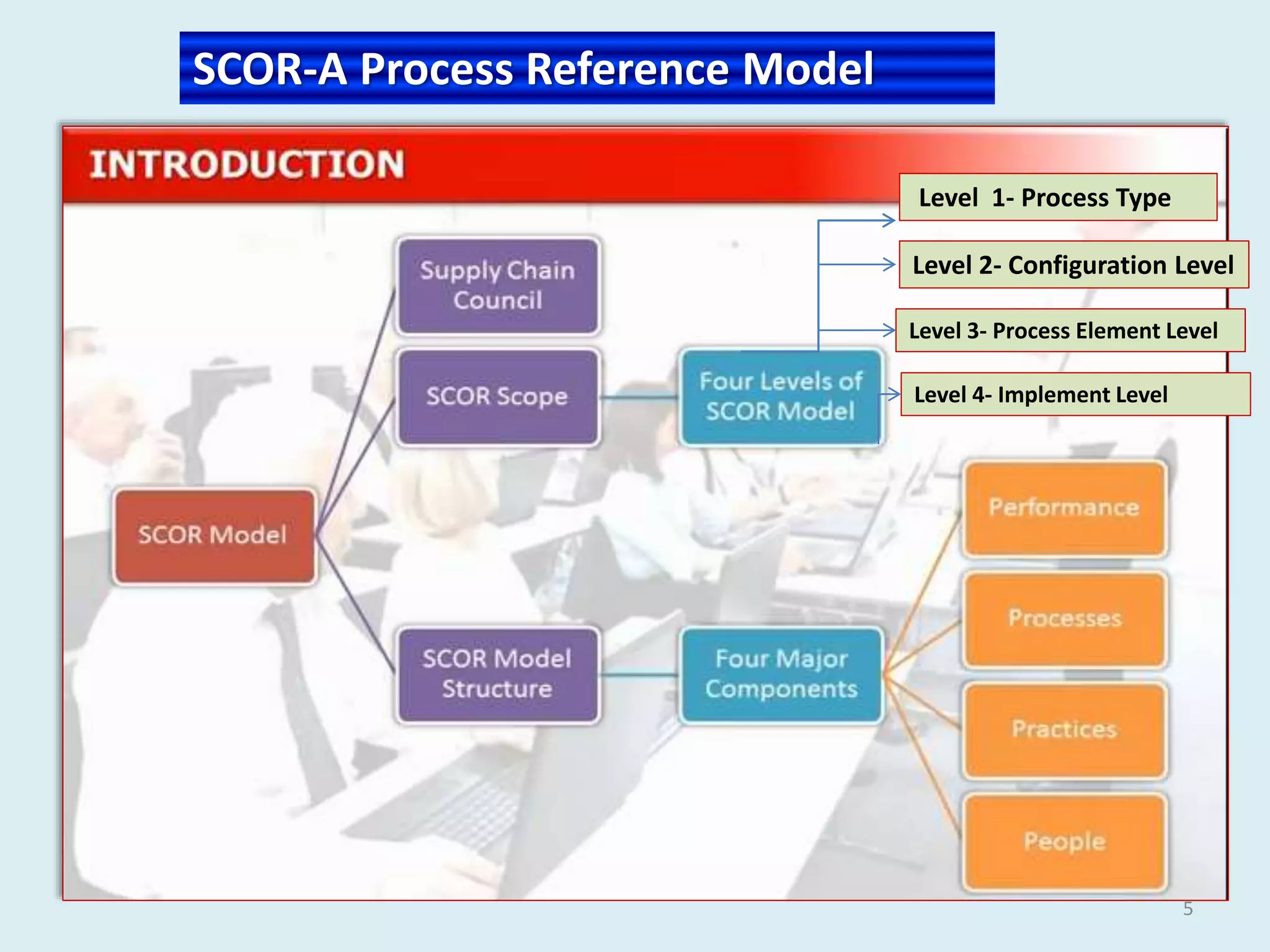

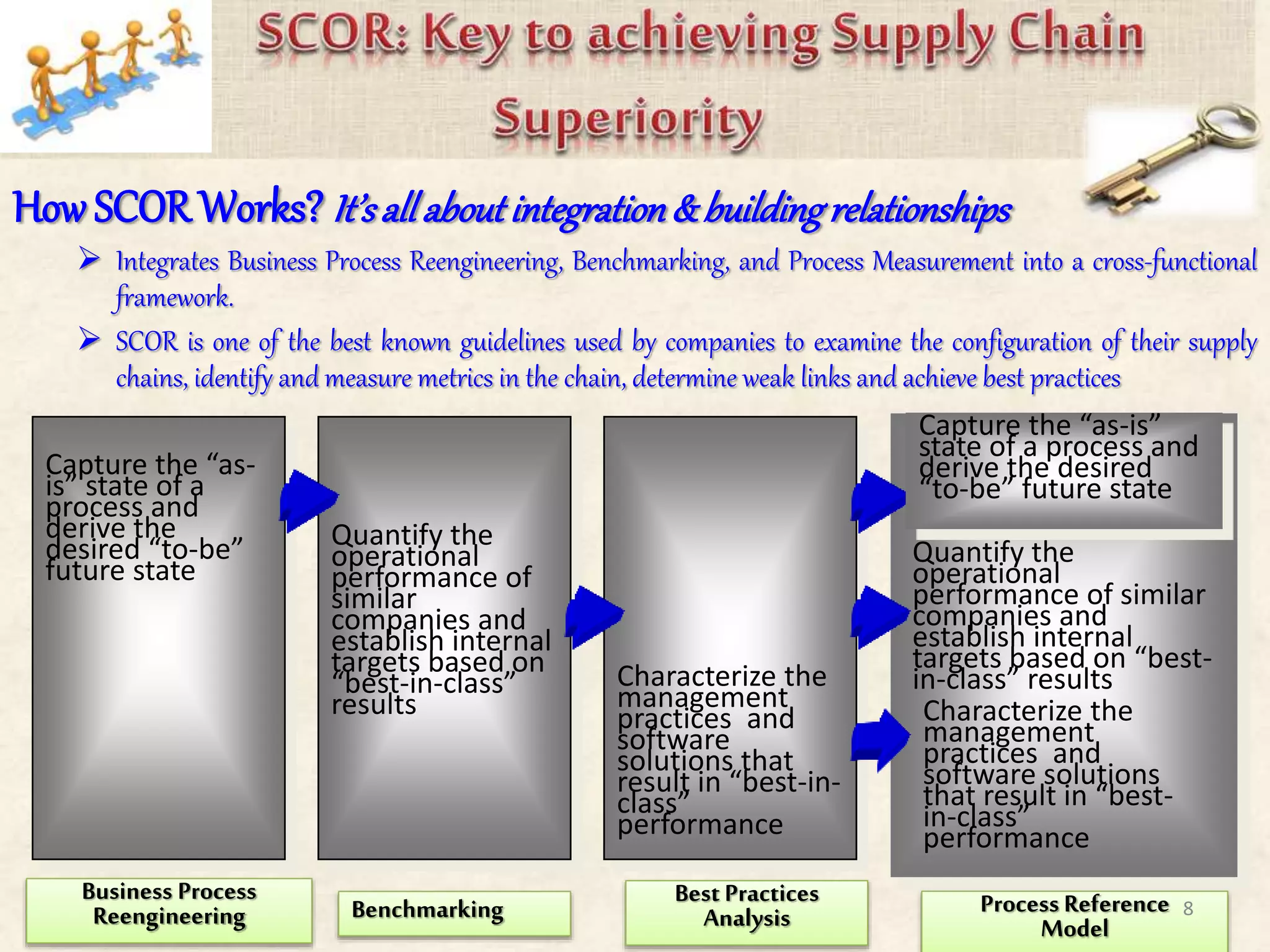

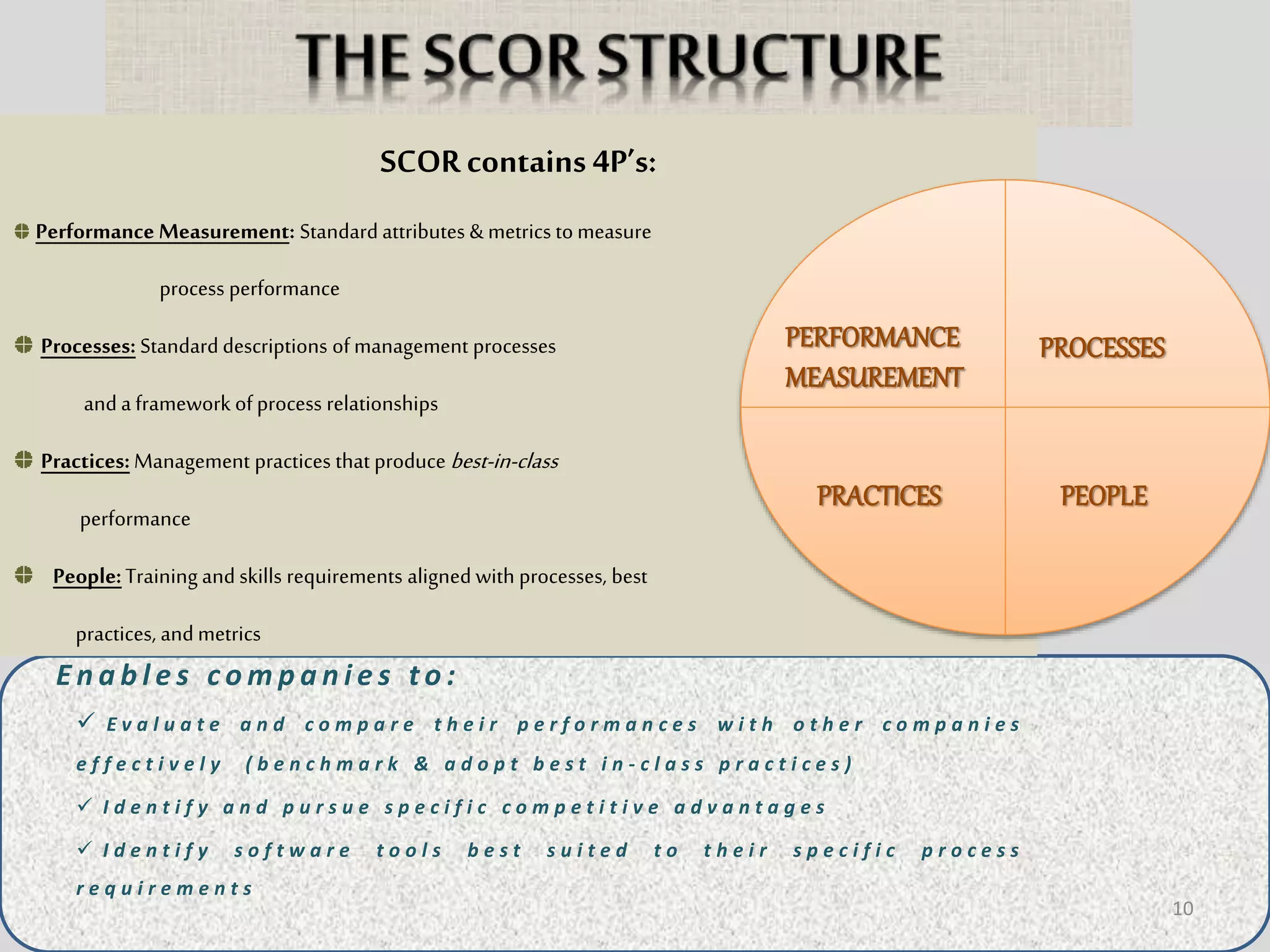

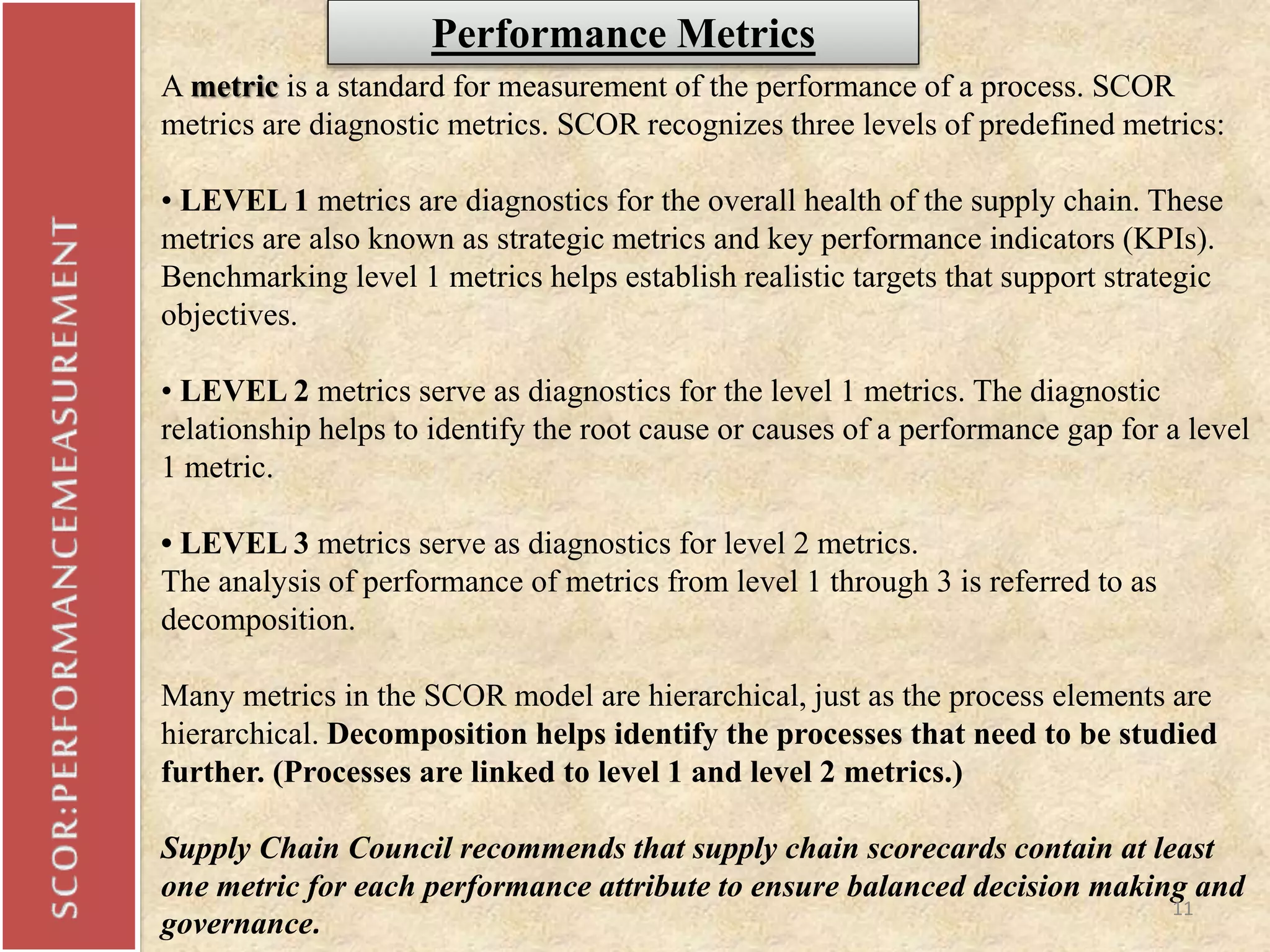

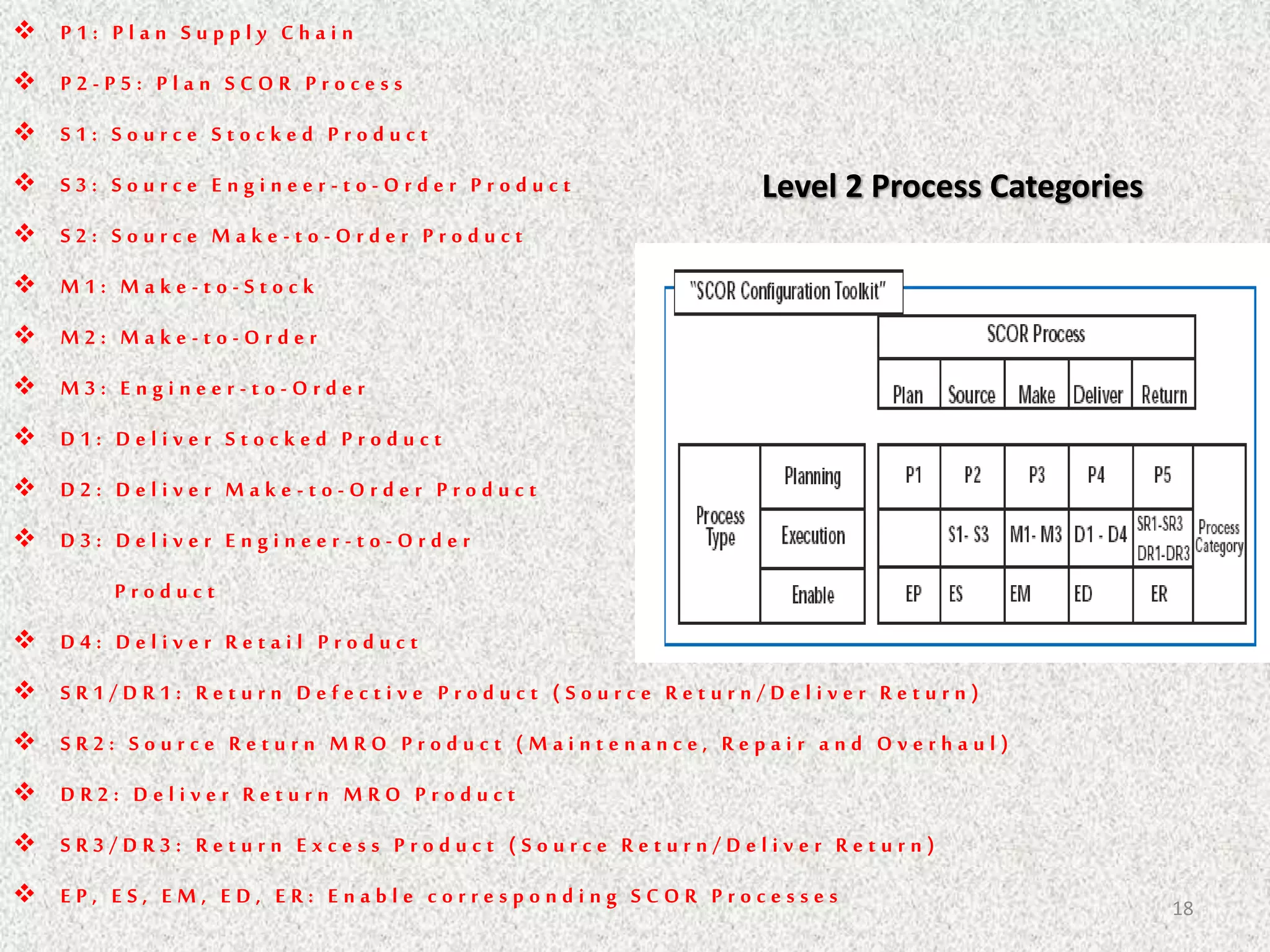

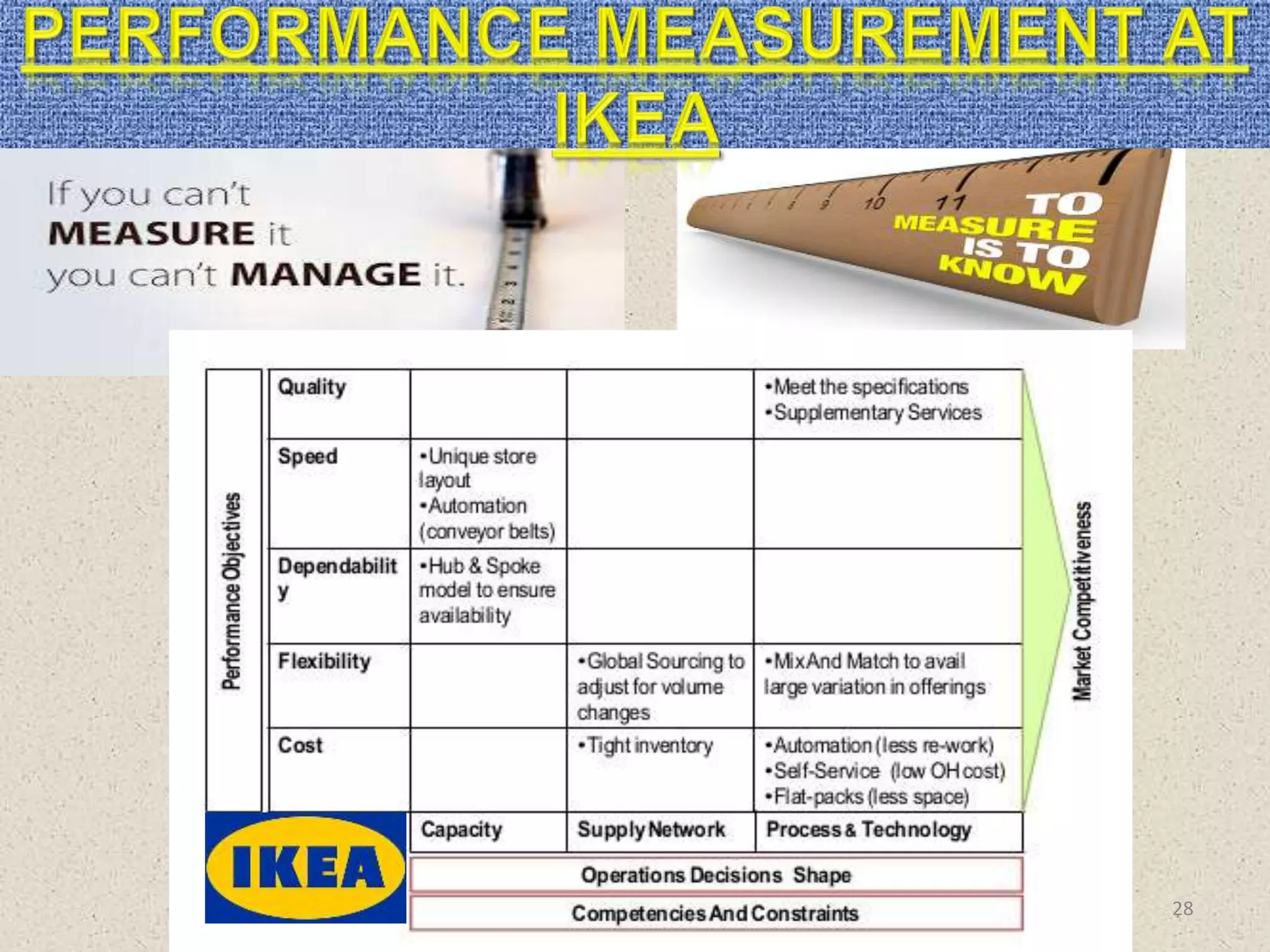

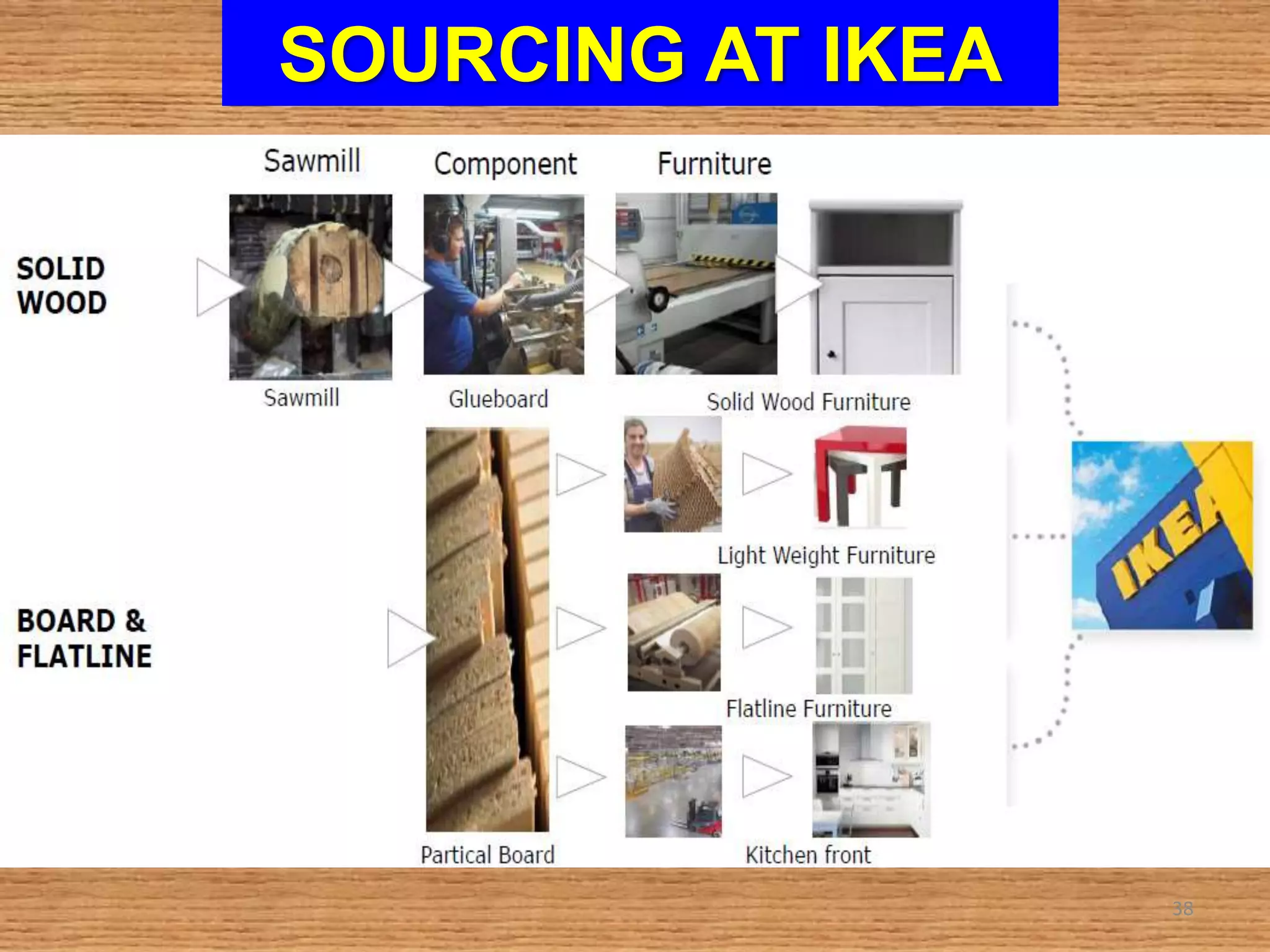

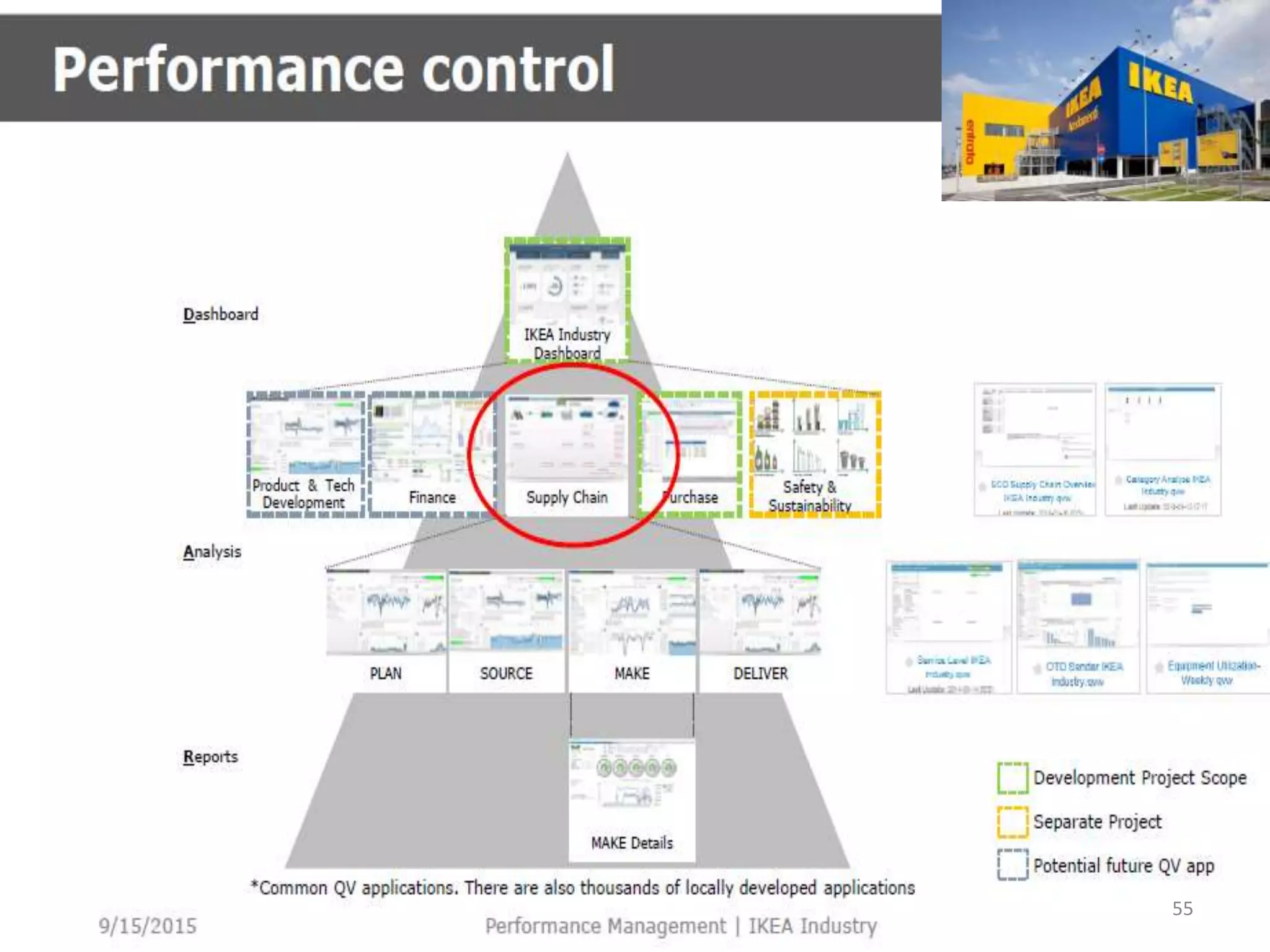

The document discusses the Supply Chain Operations Reference (SCOR) model. It was developed by the Supply Chain Council (SCC) to help standardize supply chain processes and enable effective communication. The SCOR model provides a framework to analyze supply chain performance, identify best practices, and benchmark against other companies. It covers key supply chain processes like plan, source, make, deliver, and return. The model has four levels that progressively break down processes and defines standard metrics to measure performance. Companies can use SCOR to evaluate their supply chains, improve operations, and align skills/tools with strategies. IKEA uses the SCOR model to gain efficiencies in areas like inventory planning, sourcing, manufacturing, and logistics.