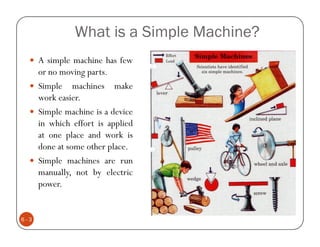

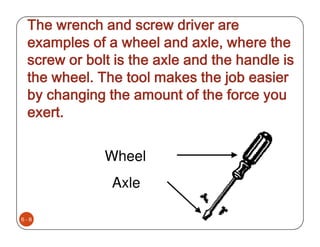

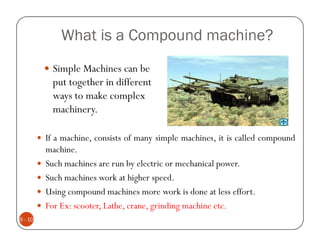

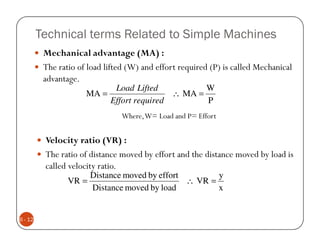

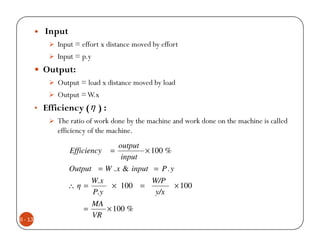

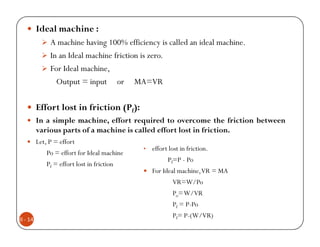

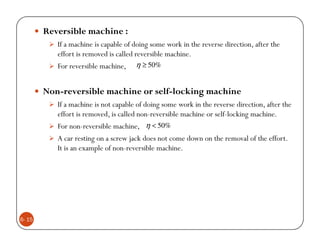

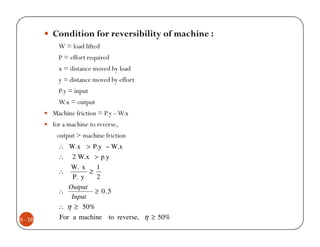

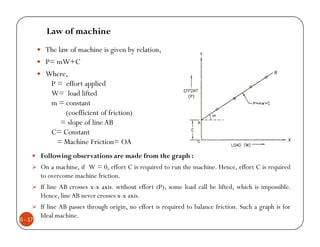

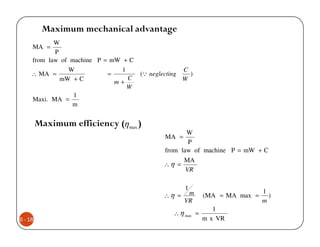

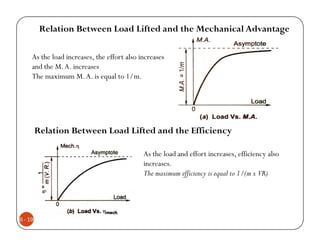

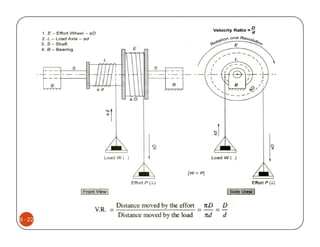

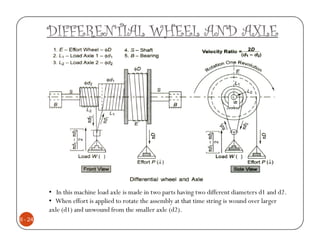

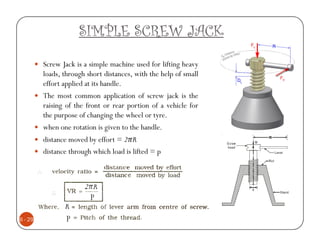

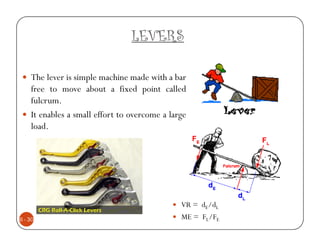

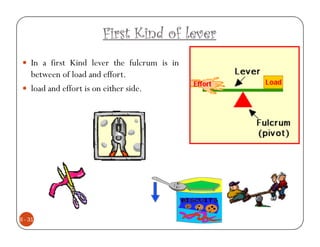

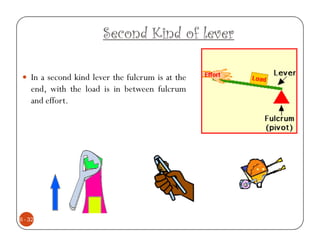

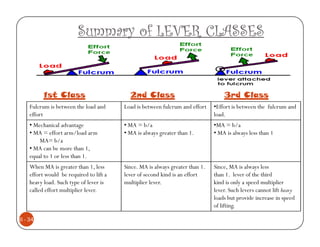

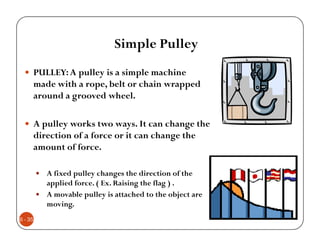

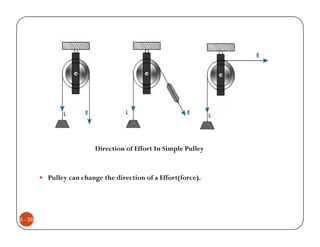

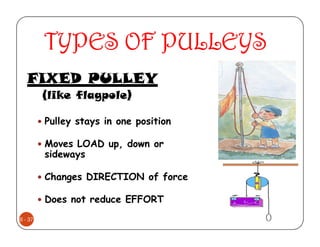

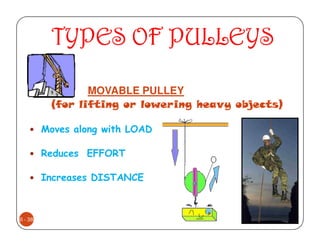

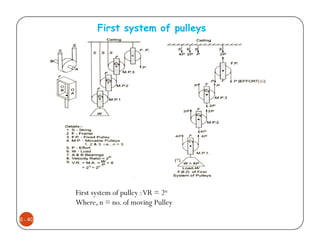

This document provides information about simple machines. It discusses different types of simple machines like the wheel and axle, screw, lever, pulley, and their uses. Simple machines make work easier by changing the amount or direction of force. They allow us to lift heavy loads using less effort. Common examples mentioned are a screwdriver and wrench, which act as a wheel and axle to make unscrewing easier. The document also covers compound machines, lifting machines, and defines terms related to simple machines like mechanical advantage and efficiency.