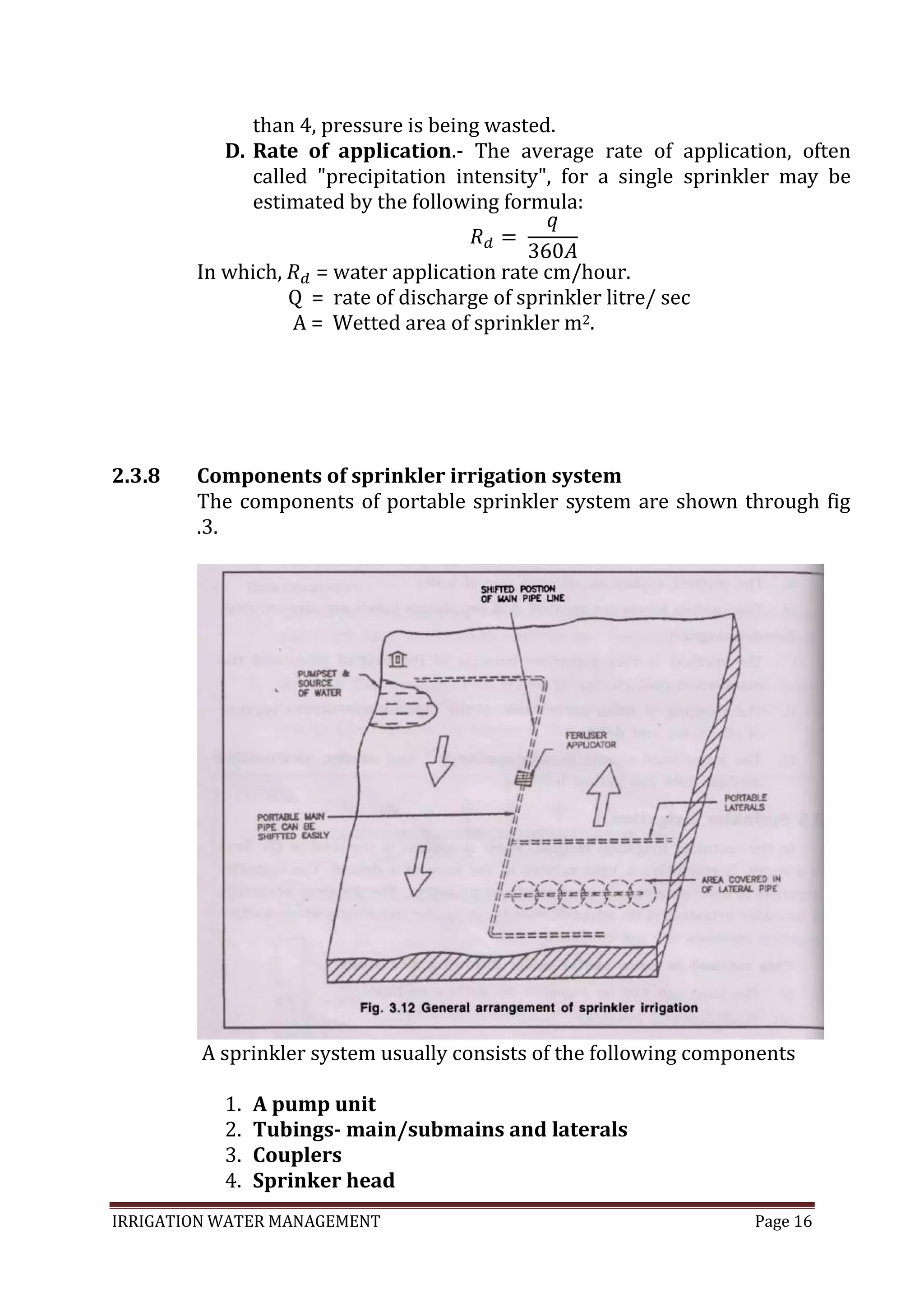

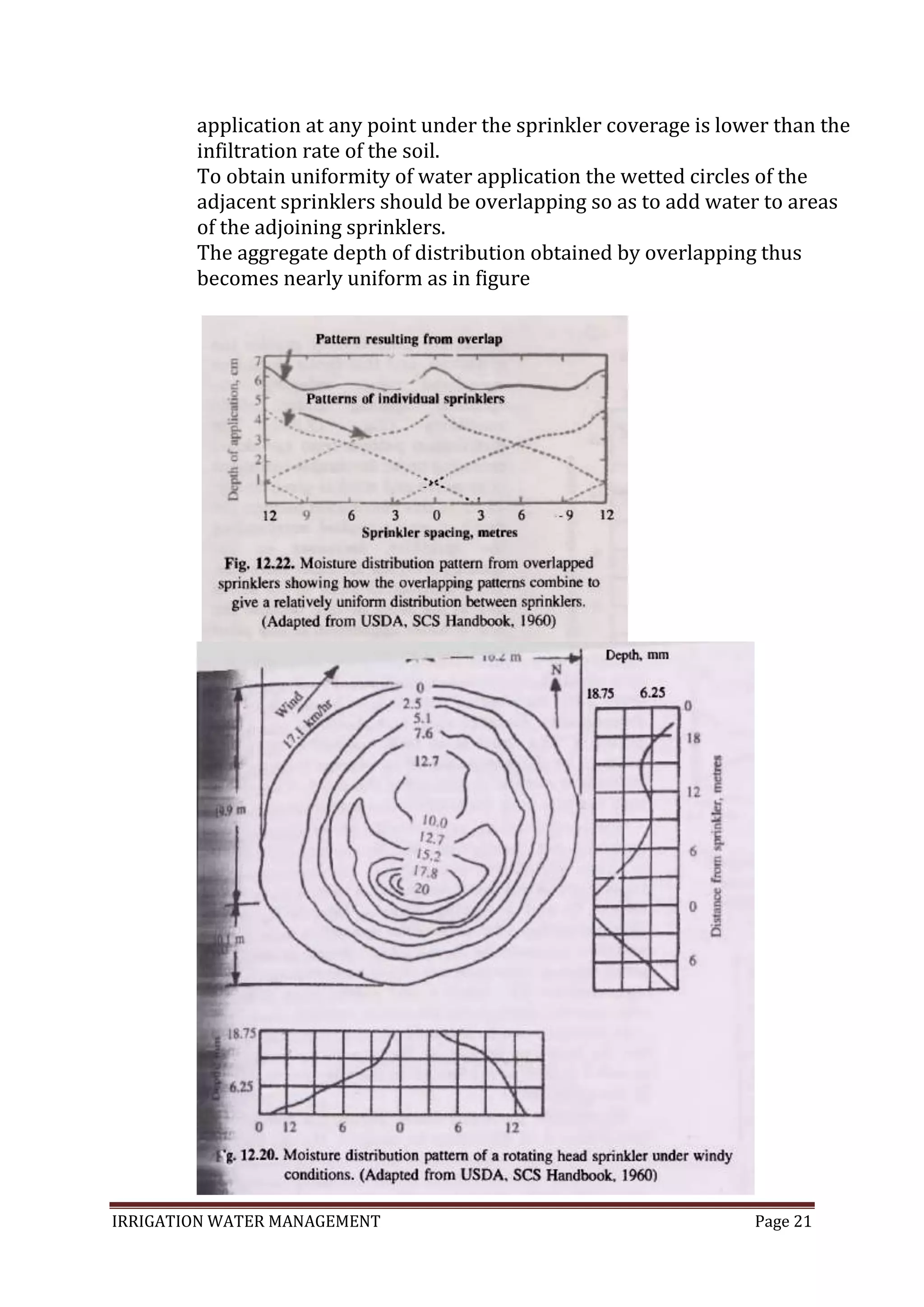

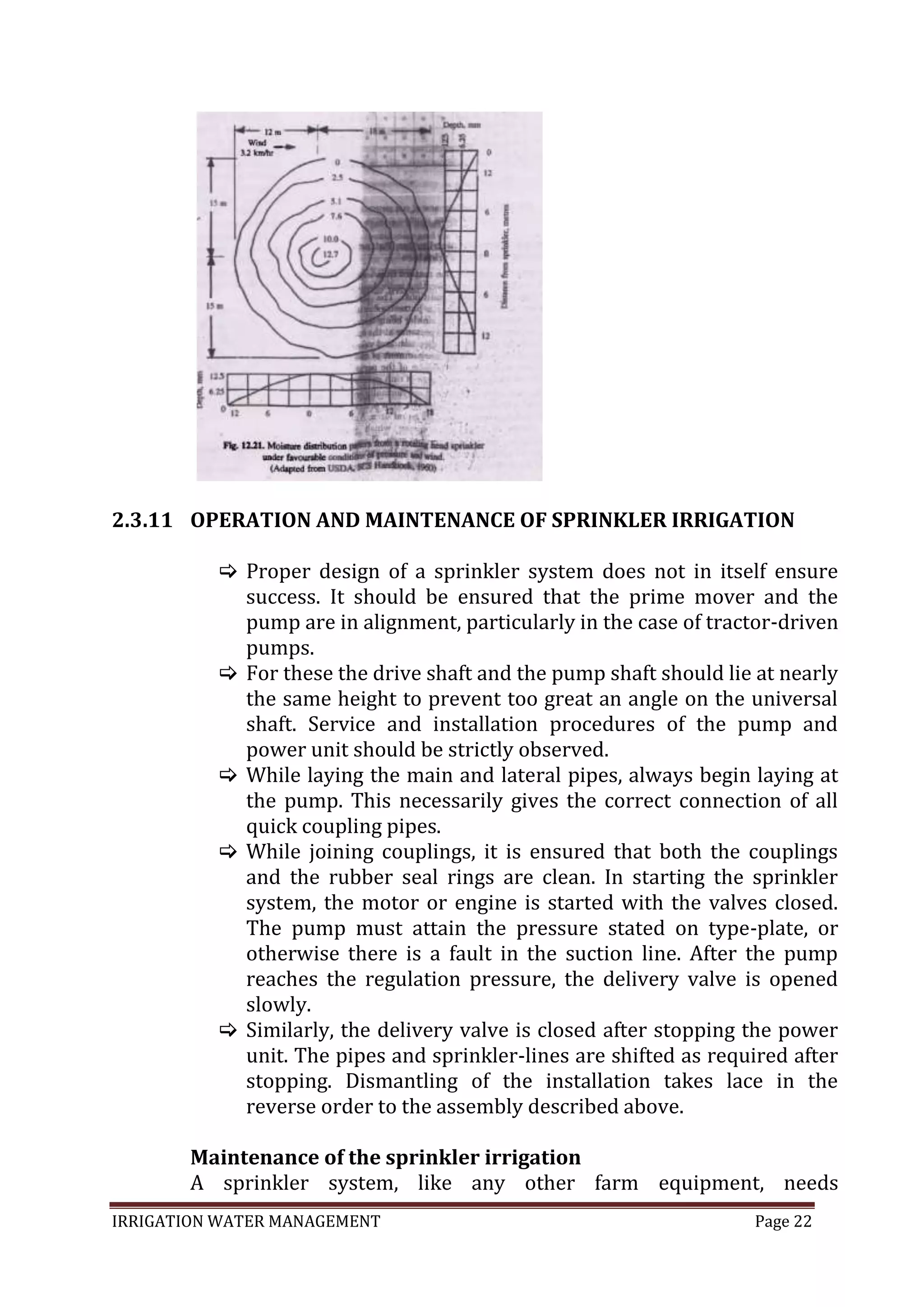

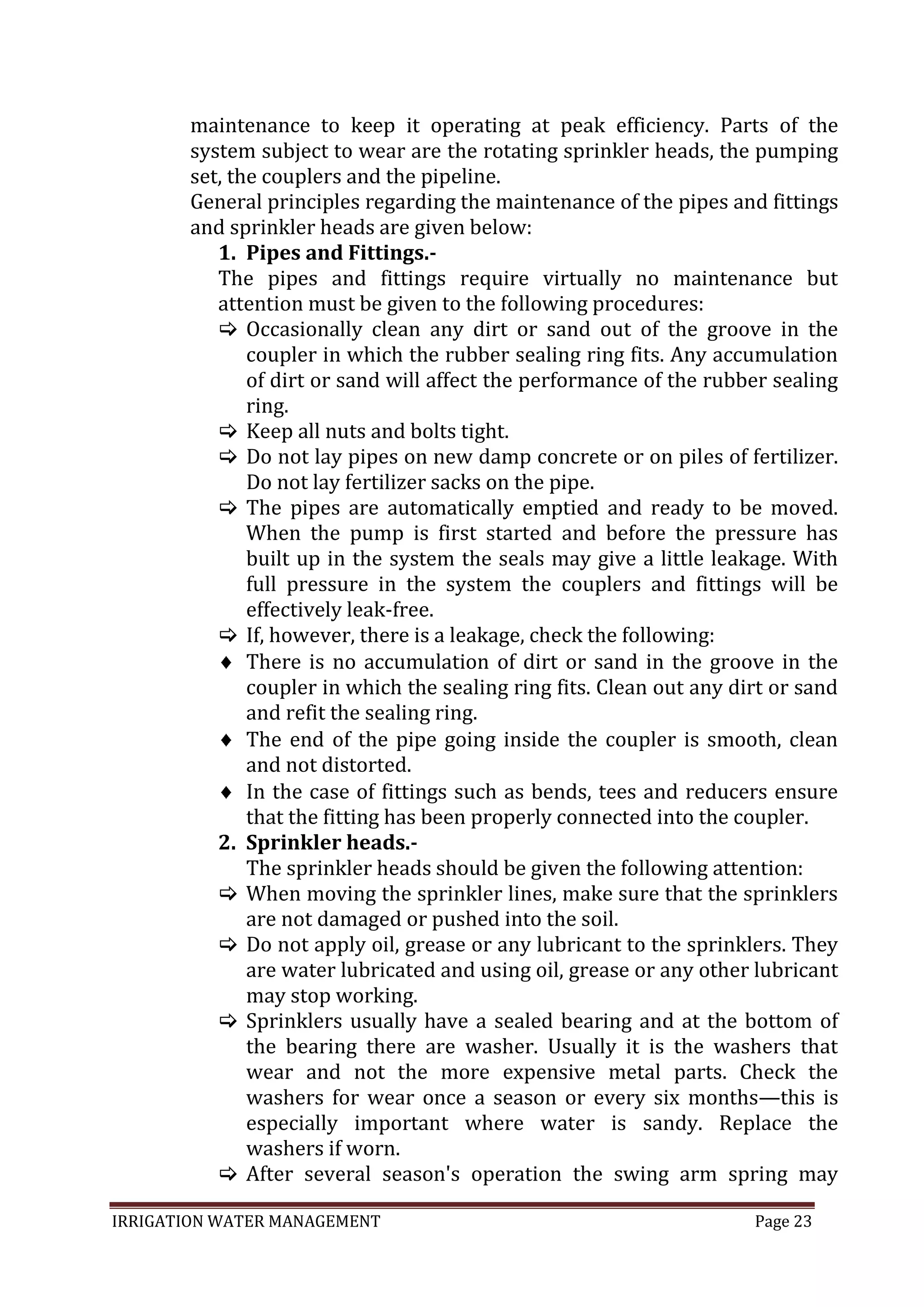

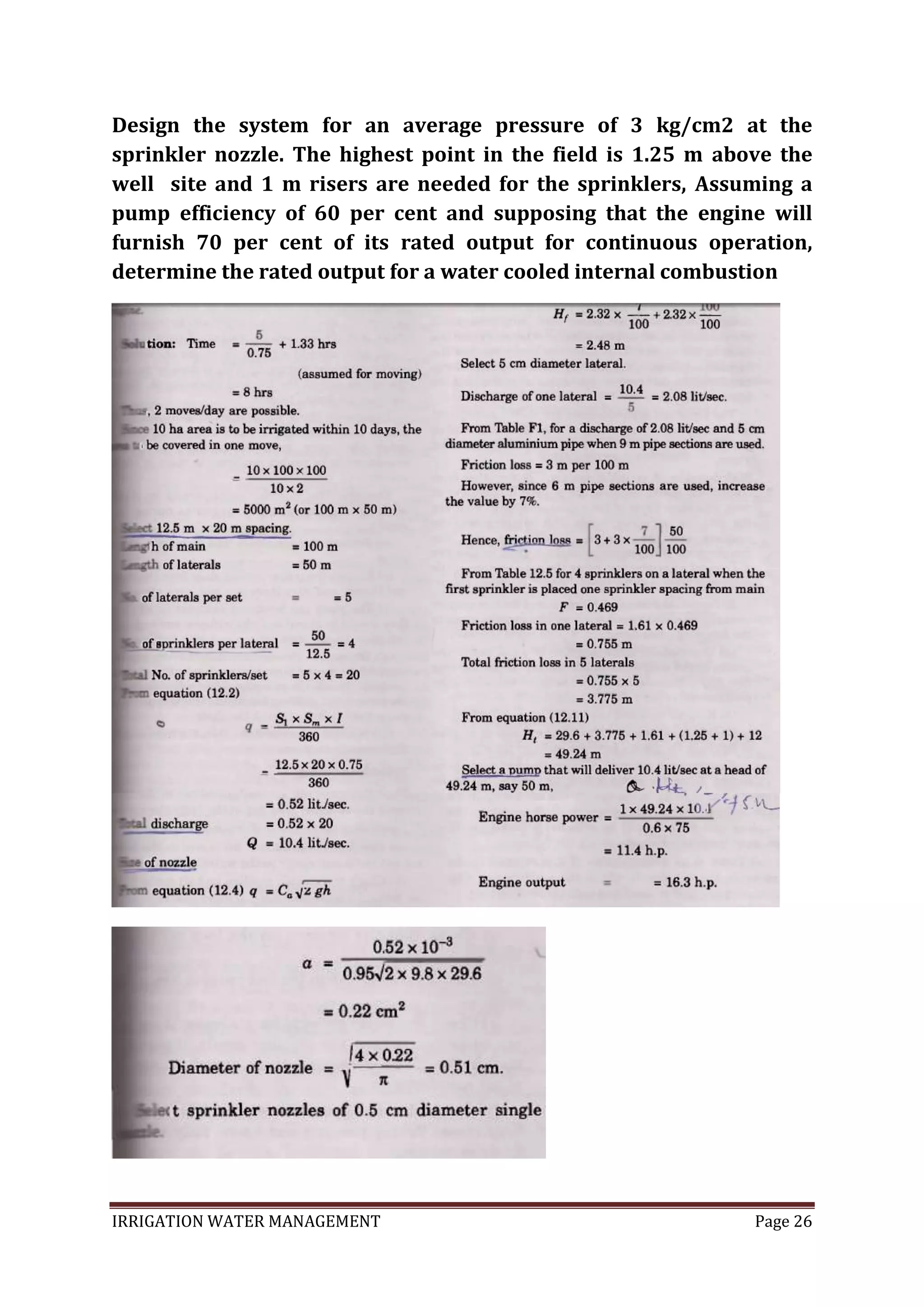

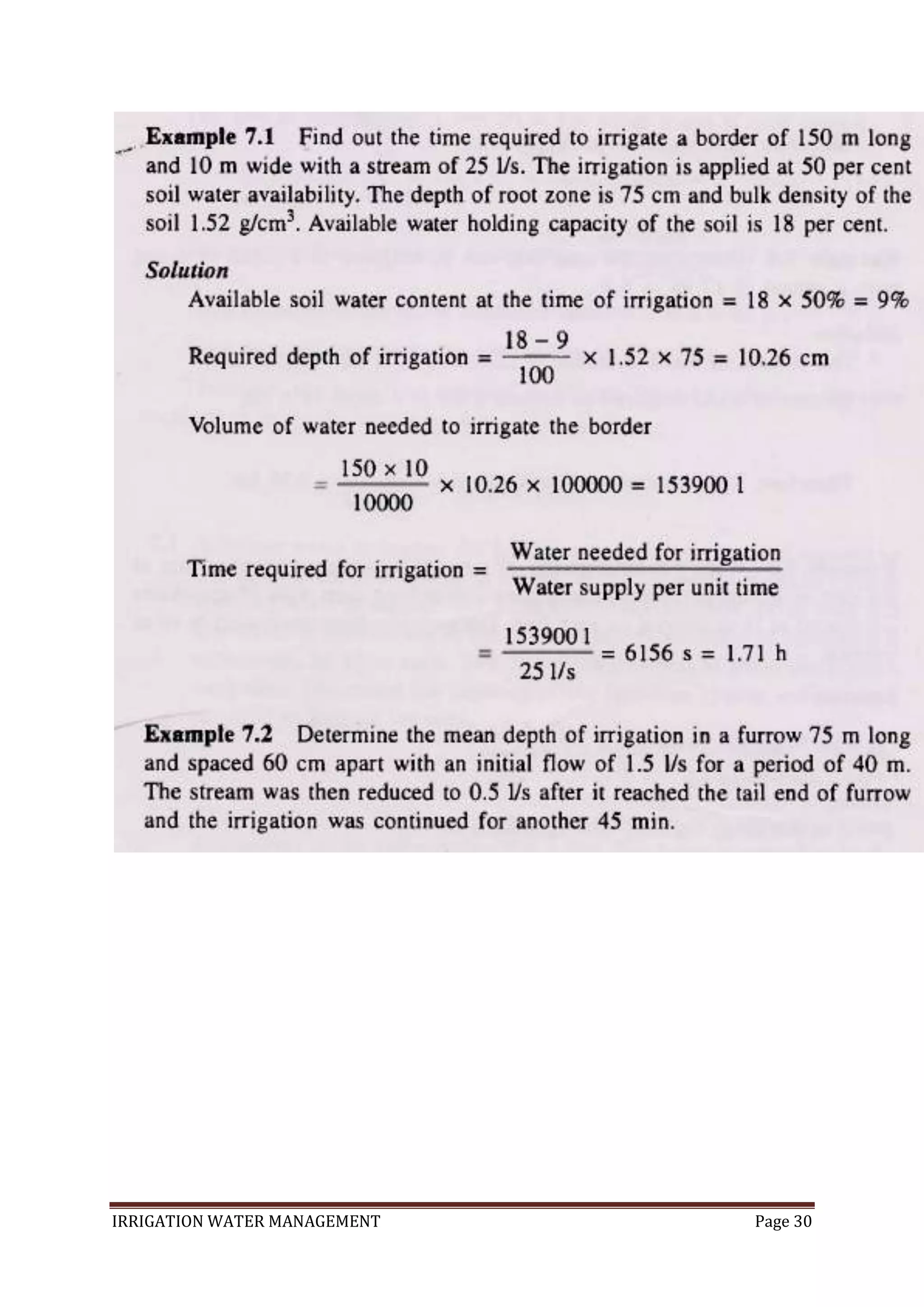

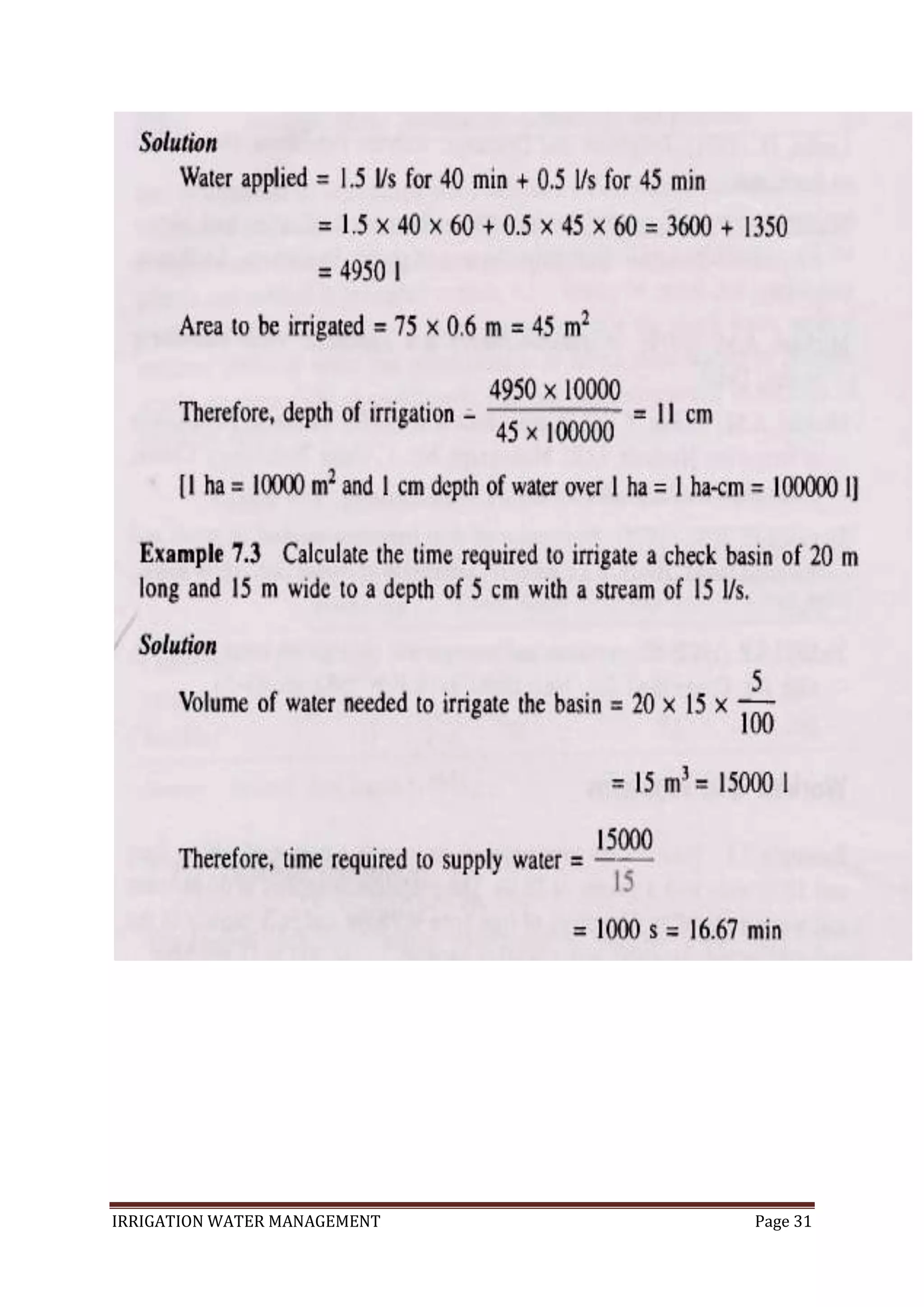

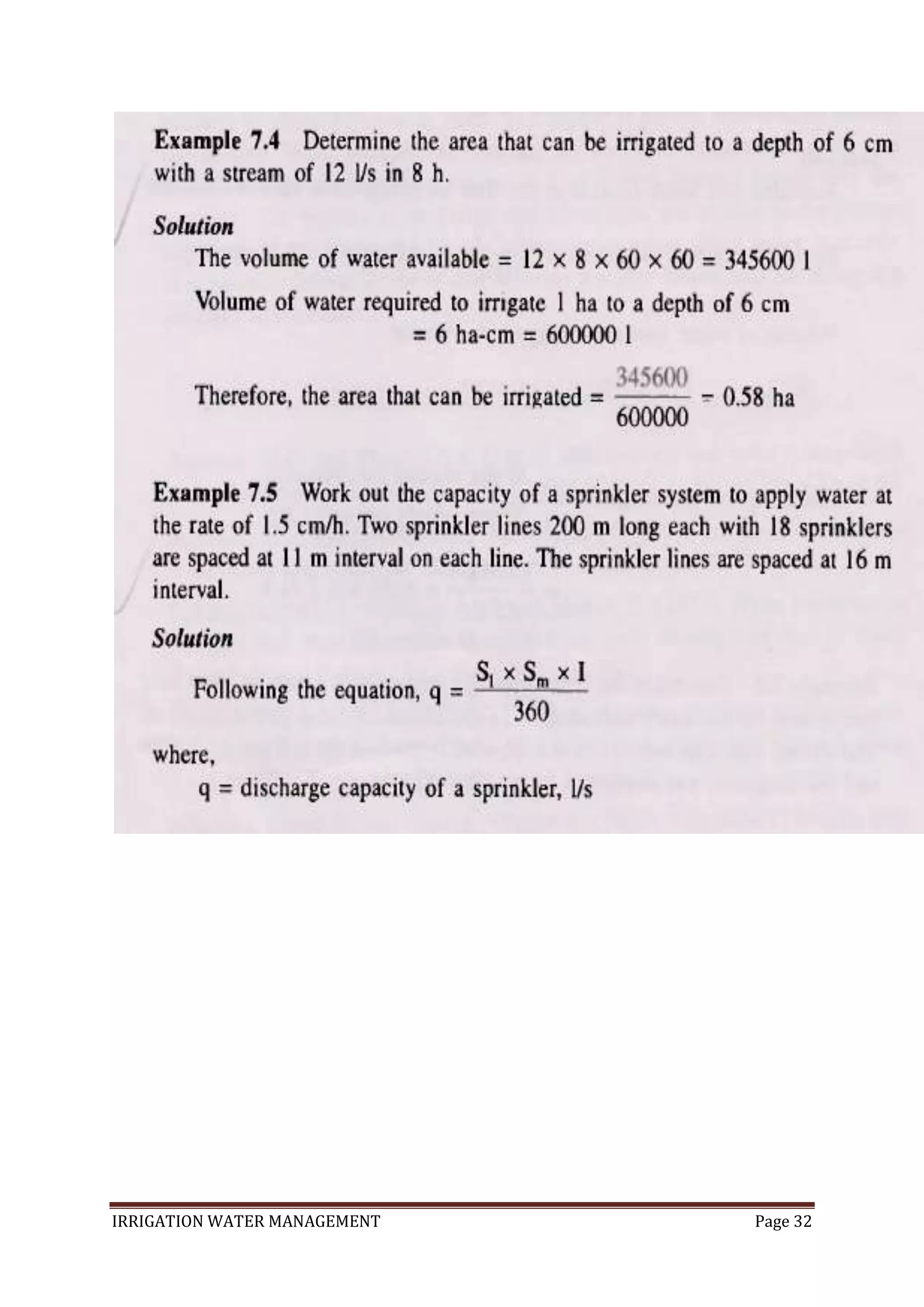

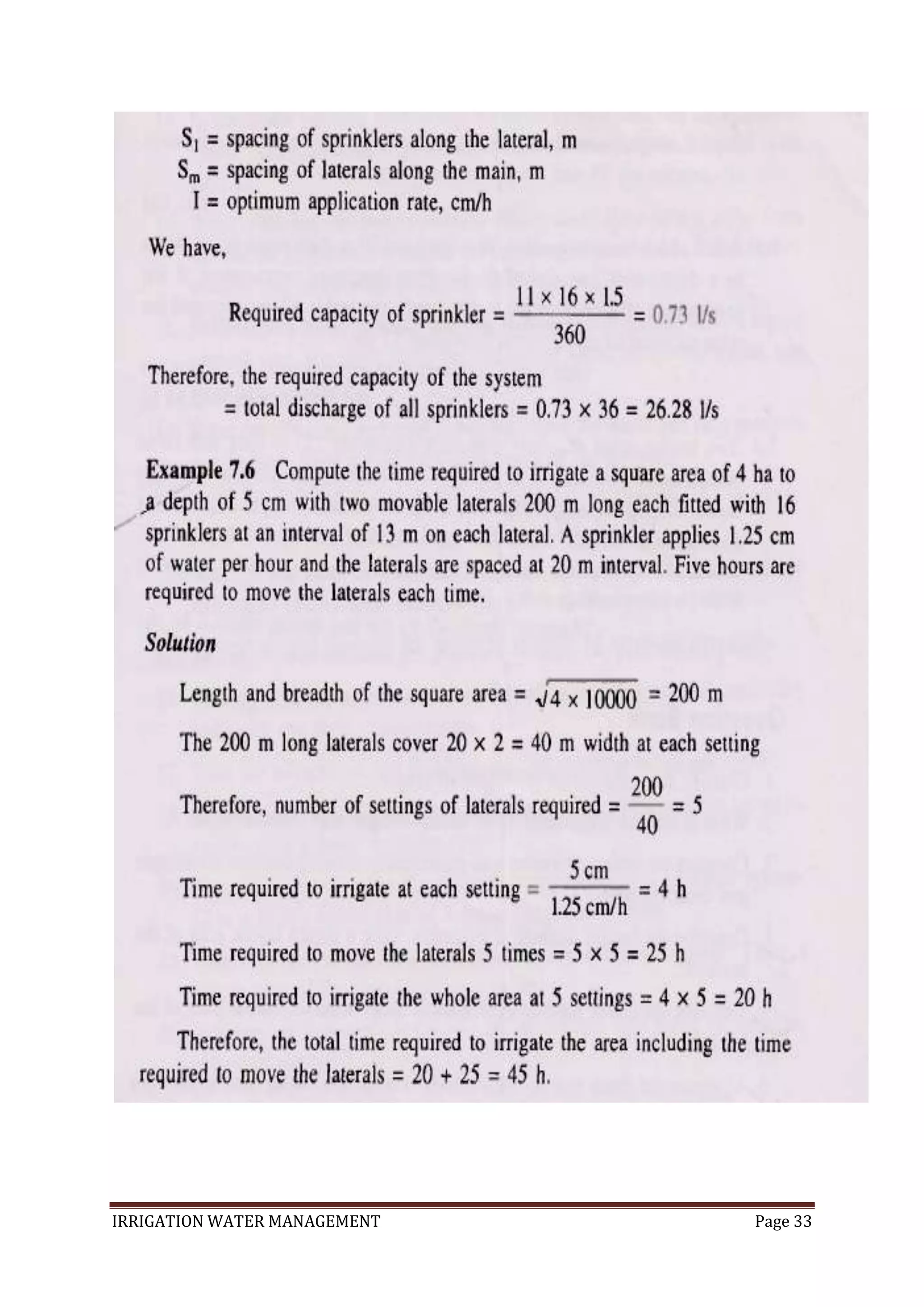

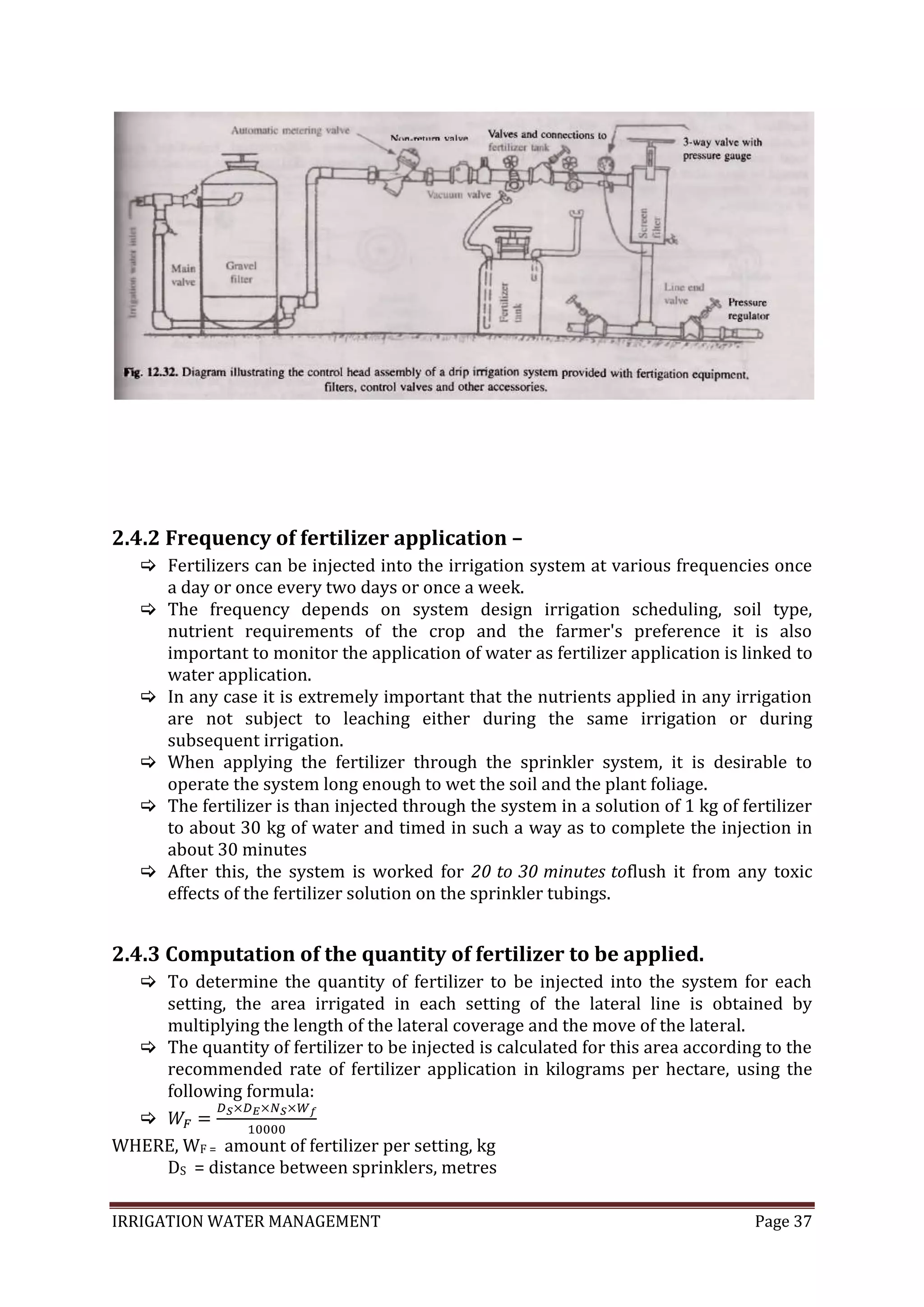

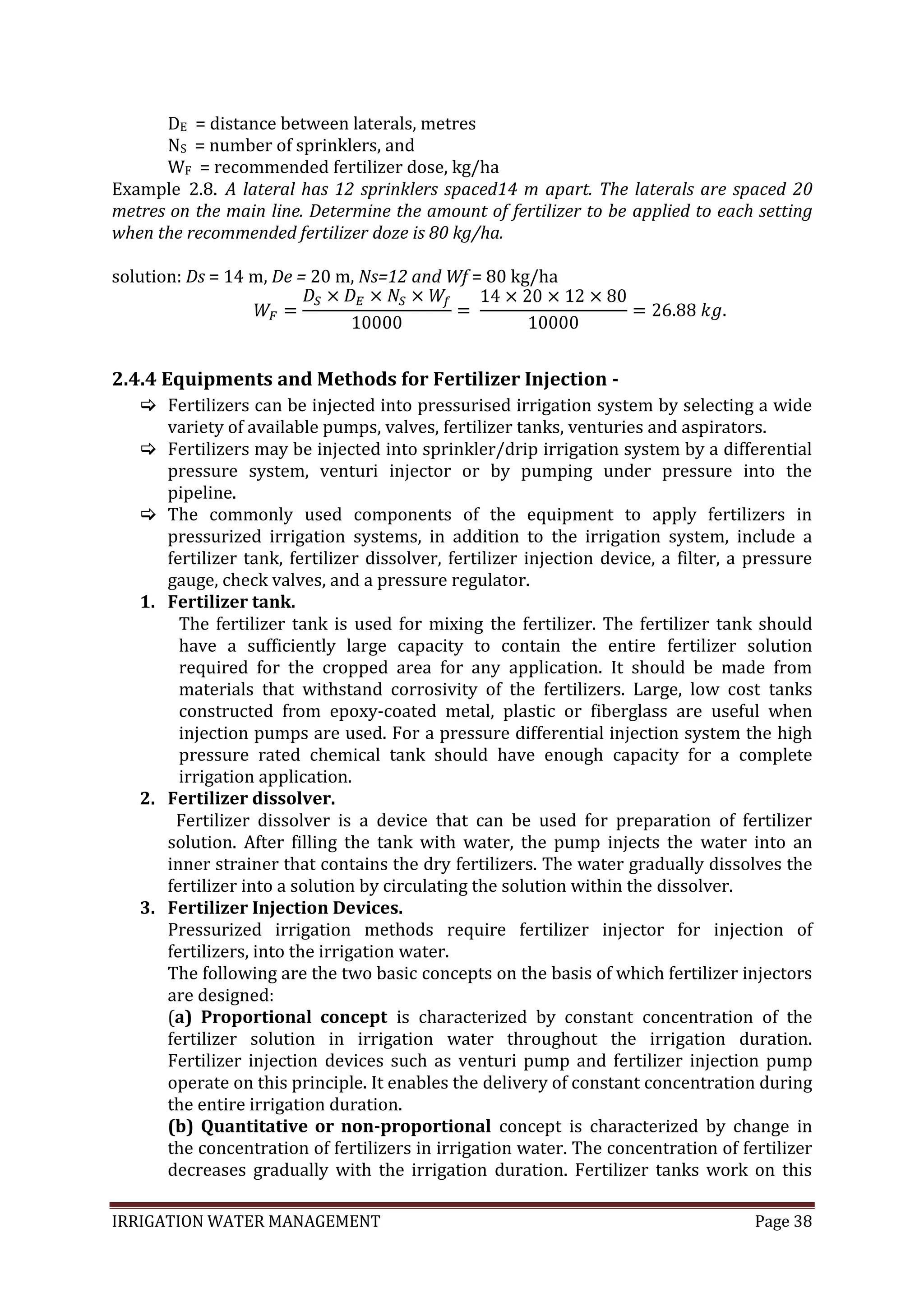

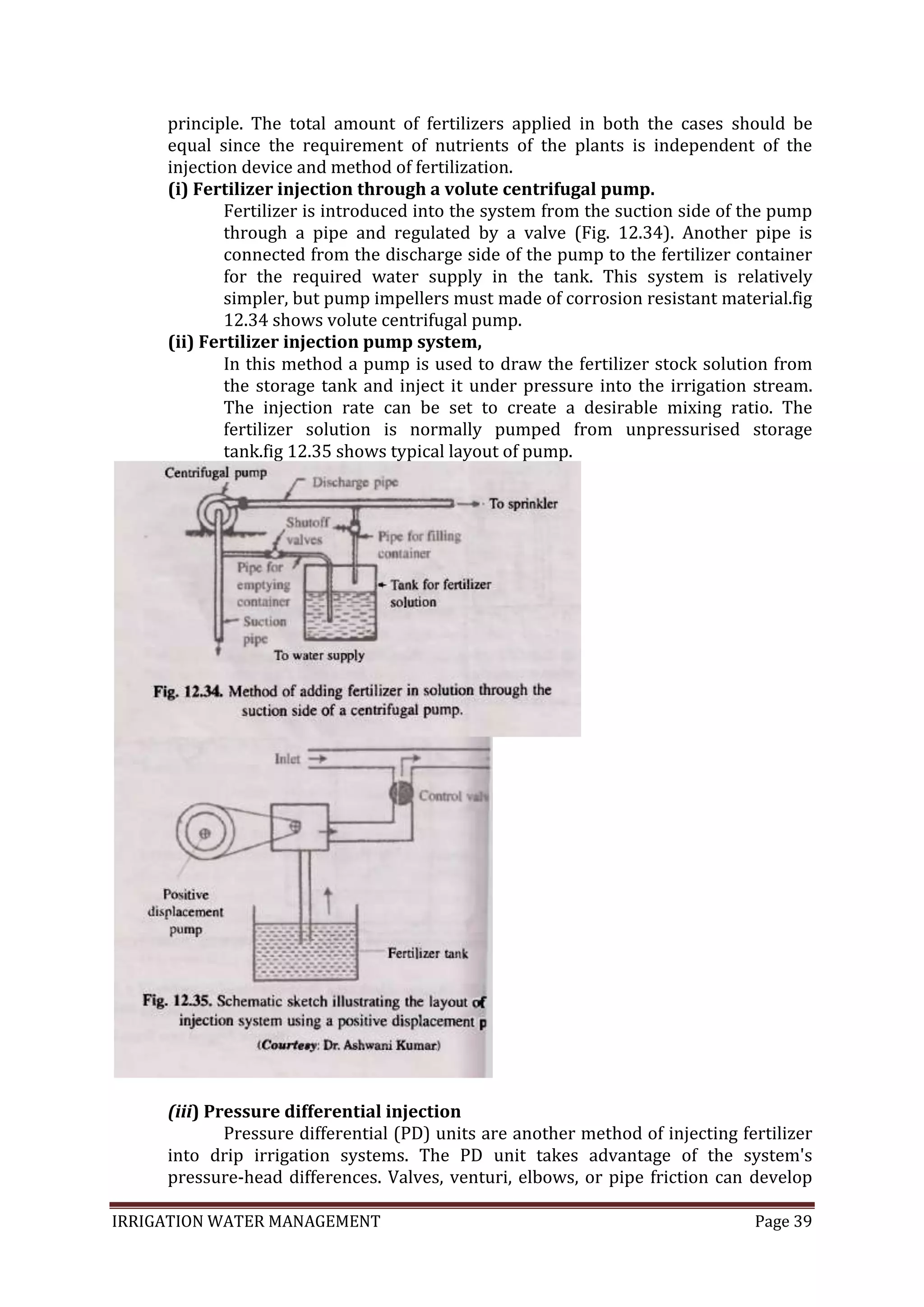

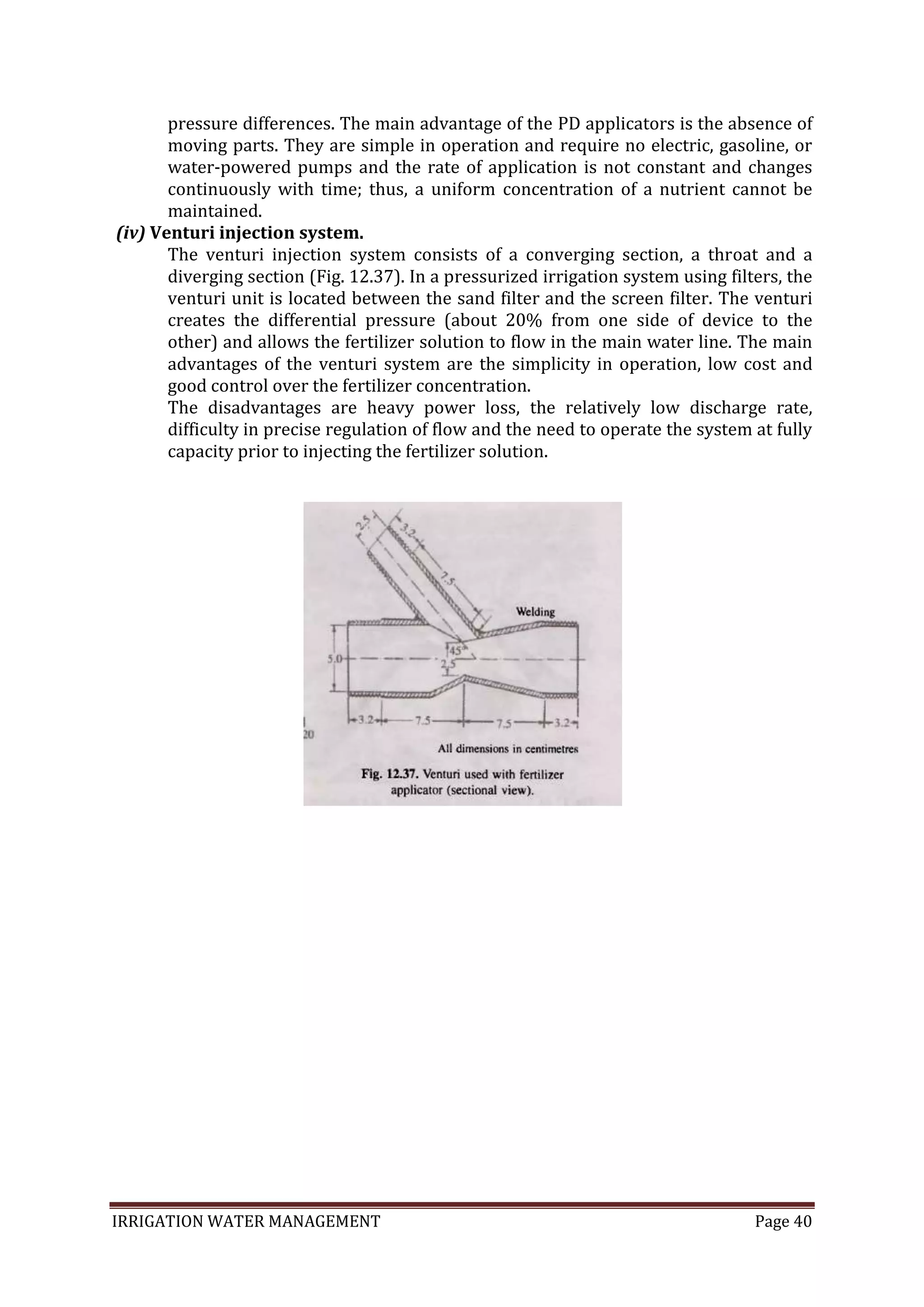

The document discusses various irrigation methods including sprinkler irrigation. It describes how remote sensing and GIS technologies can help with tasks like identifying land use patterns, crop nutrient deficiencies, optimal water levels for crops, and cropping patterns. The document also outlines the advantages and limitations of different irrigation methods such as sprinkler irrigation and subsurface irrigation.