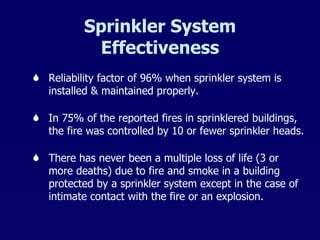

The document discusses automatic sprinkler systems, including their purpose of discharging an extinguishing agent during the incipient stage of a fire. It notes that sprinkler systems have a 96% reliability rate when installed and maintained properly, and that in 75% of fires in sprinklered buildings, 10 or fewer sprinkler heads controlled the fire. The key components of sprinkler systems are described as the water supply, distribution piping, sprinkler heads, and valves.