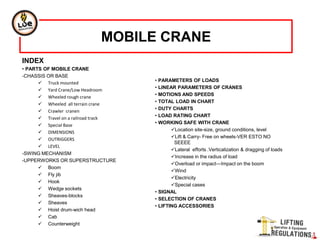

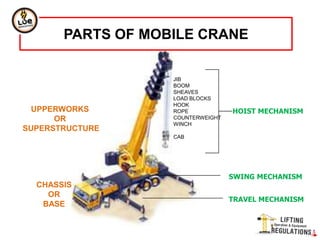

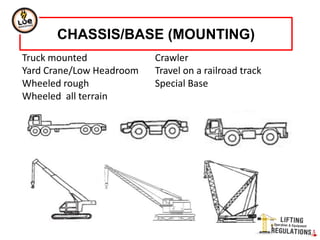

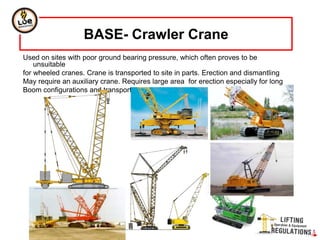

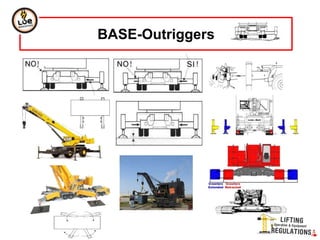

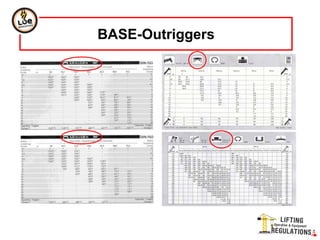

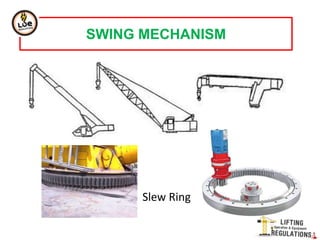

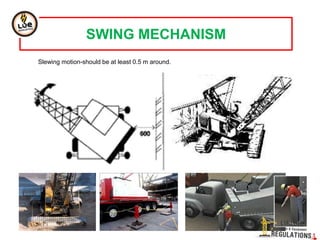

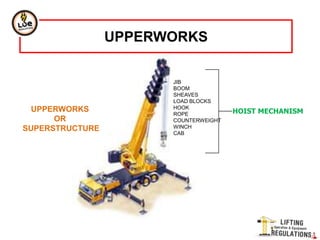

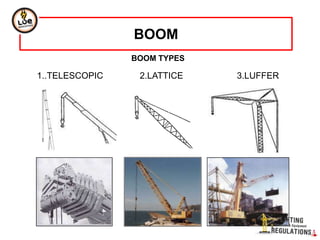

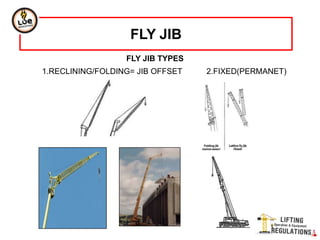

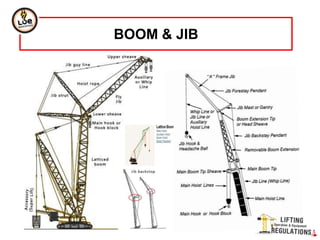

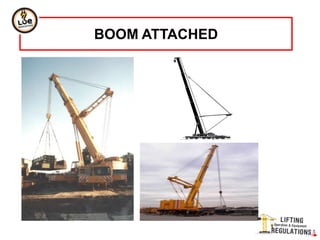

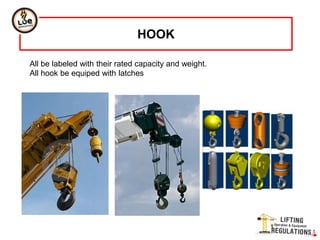

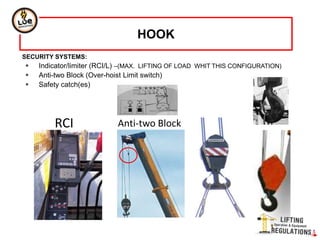

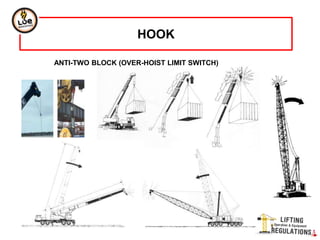

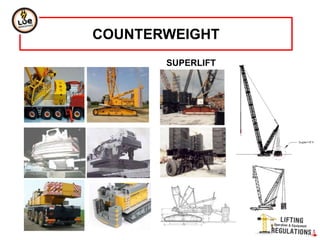

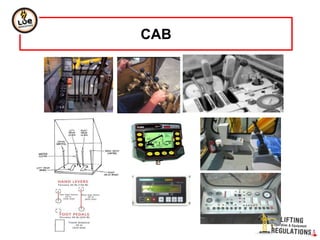

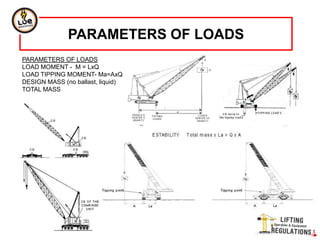

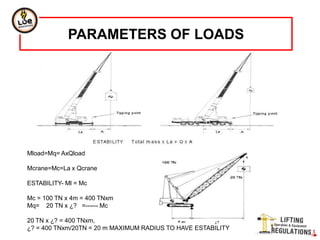

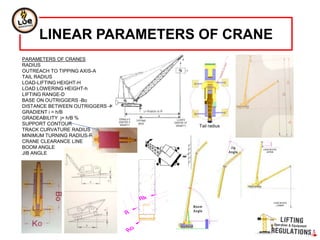

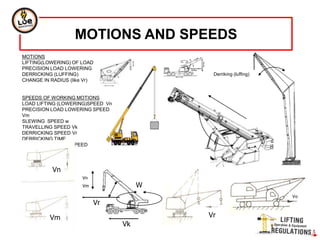

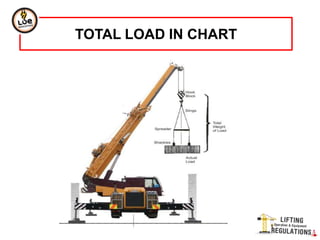

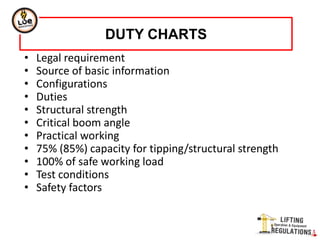

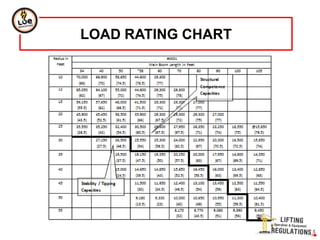

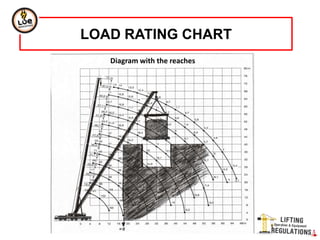

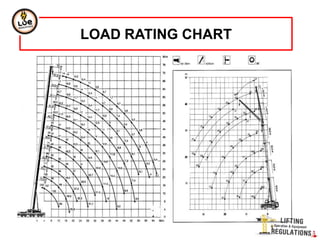

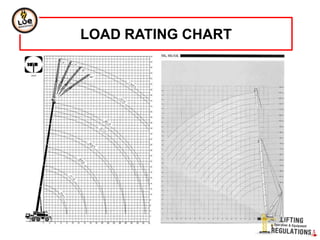

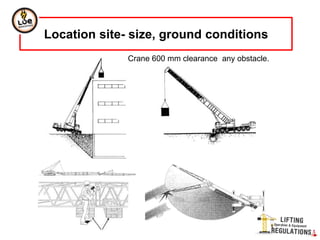

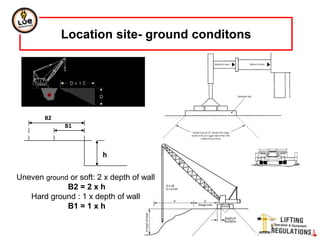

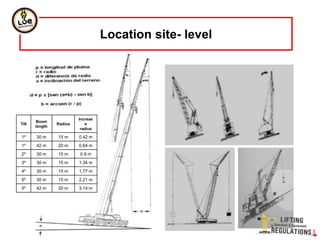

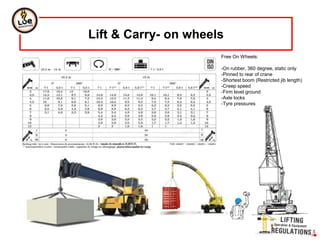

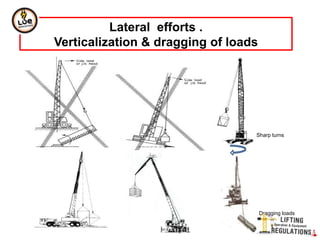

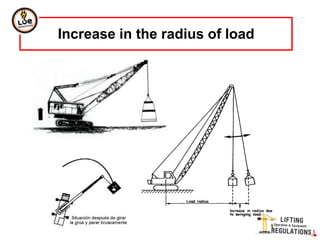

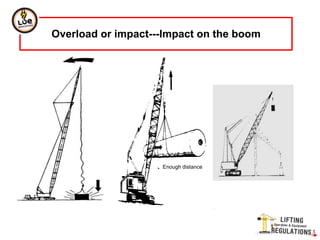

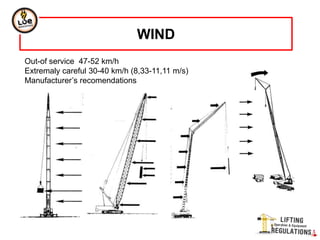

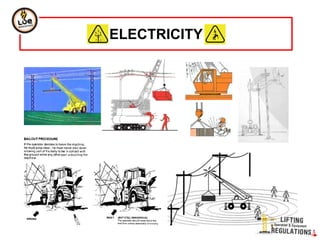

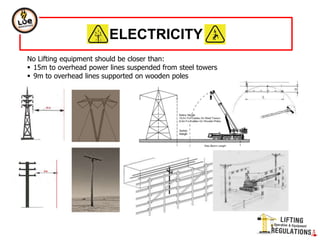

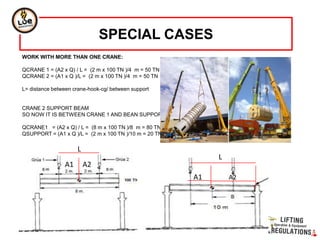

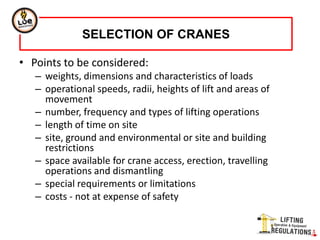

This document provides an overview of mobile crane regulations around the world. It discusses the parts of mobile cranes including the chassis/base, upperworks, swing mechanism, and parameters considered for safe operation. Load charts and duty charts are described which specify the rated capacity of cranes under different configurations. Factors that influence safe working like ground conditions, wind, electricity hazards and multi-crane lifts are also covered.