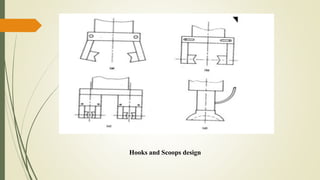

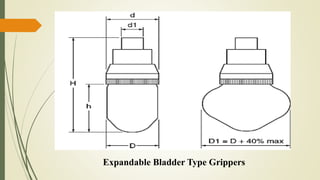

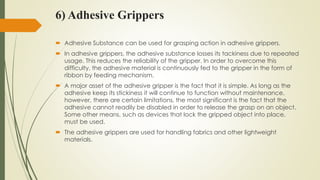

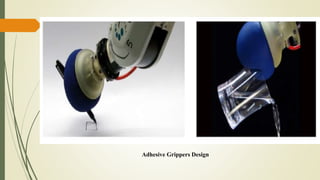

The document discusses different types of end effectors used in robotics, specifically focusing on grippers. It describes two main types of end effectors - grippers and tools. Grippers are used for holding parts and objects, and come in several varieties, including mechanical grippers, hooks/scoops, magnetic grippers, vacuum grippers, expandable bladder grippers, and adhesive grippers. Each type is suited to different applications and has unique advantages and limitations. The document provides details on the design and use of each gripper type.