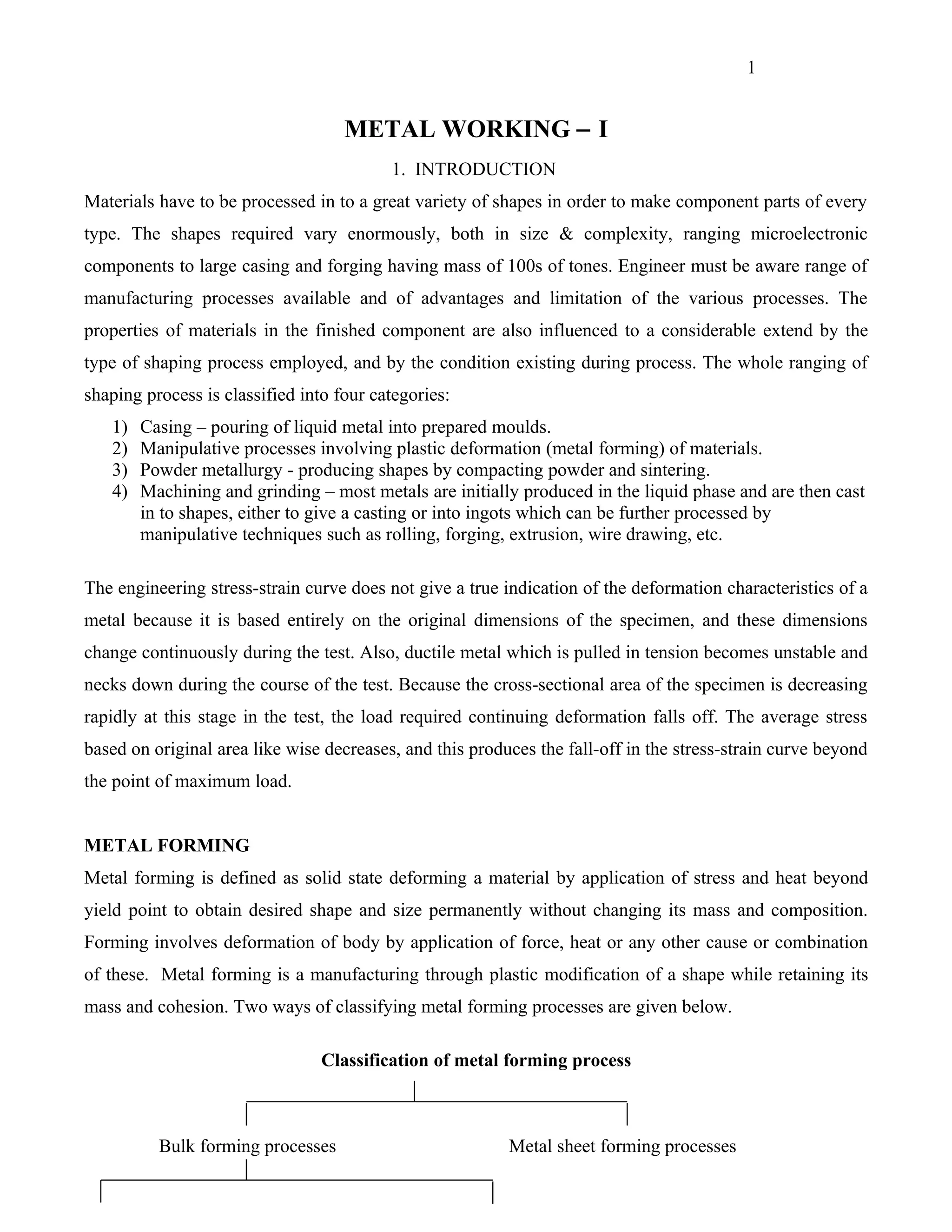

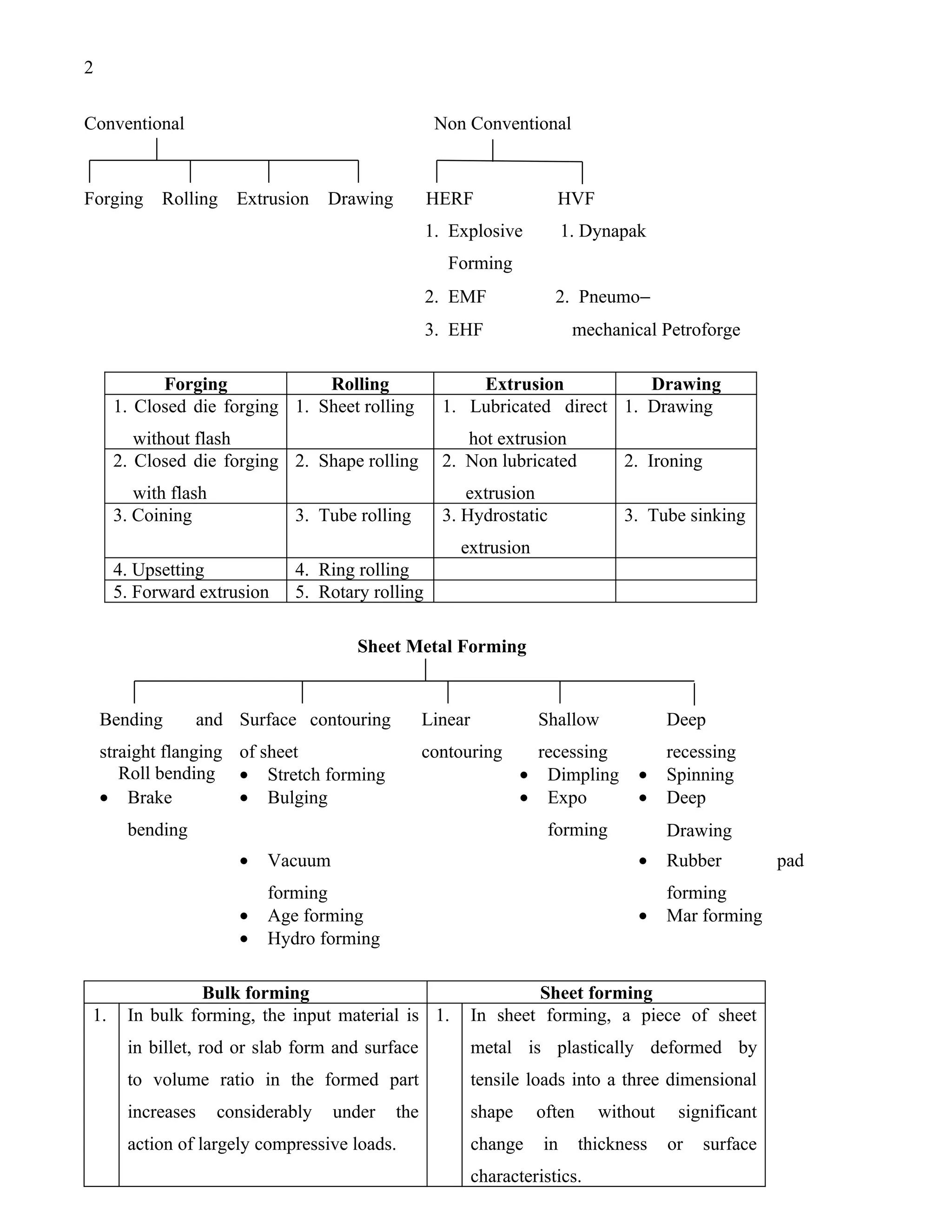

1. The document discusses various metal working and forming processes such as casting, forging, rolling, extrusion, drawing, and powder metallurgy. It classifies the processes into bulk forming and sheet metal forming.

2. Bulk forming involves large plastic deformation of billets, rods or slabs through compressive loads to significantly change the shape or cross-section. Sheet forming uses tensile loads to plastically deform sheet metal into three-dimensional shapes with less thickness change.

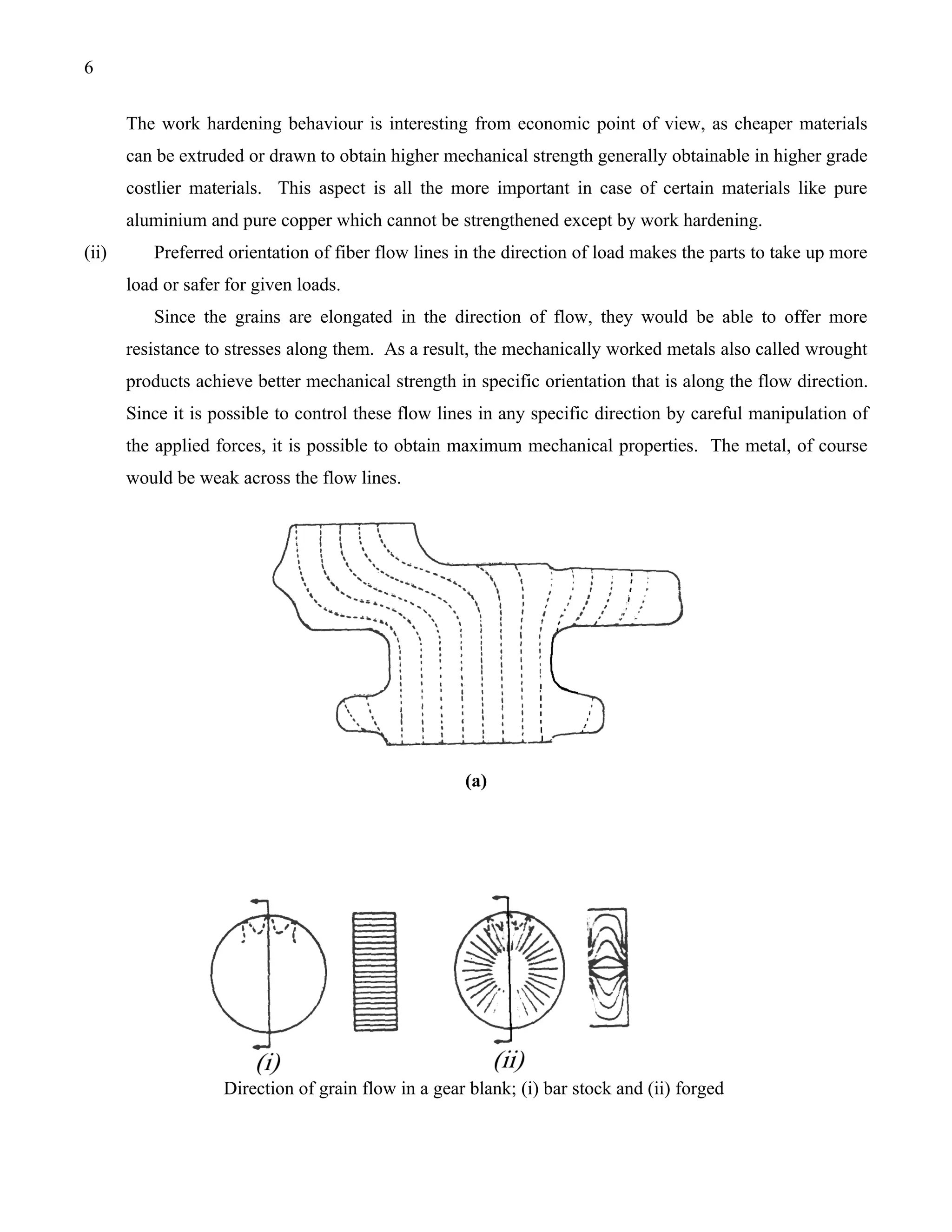

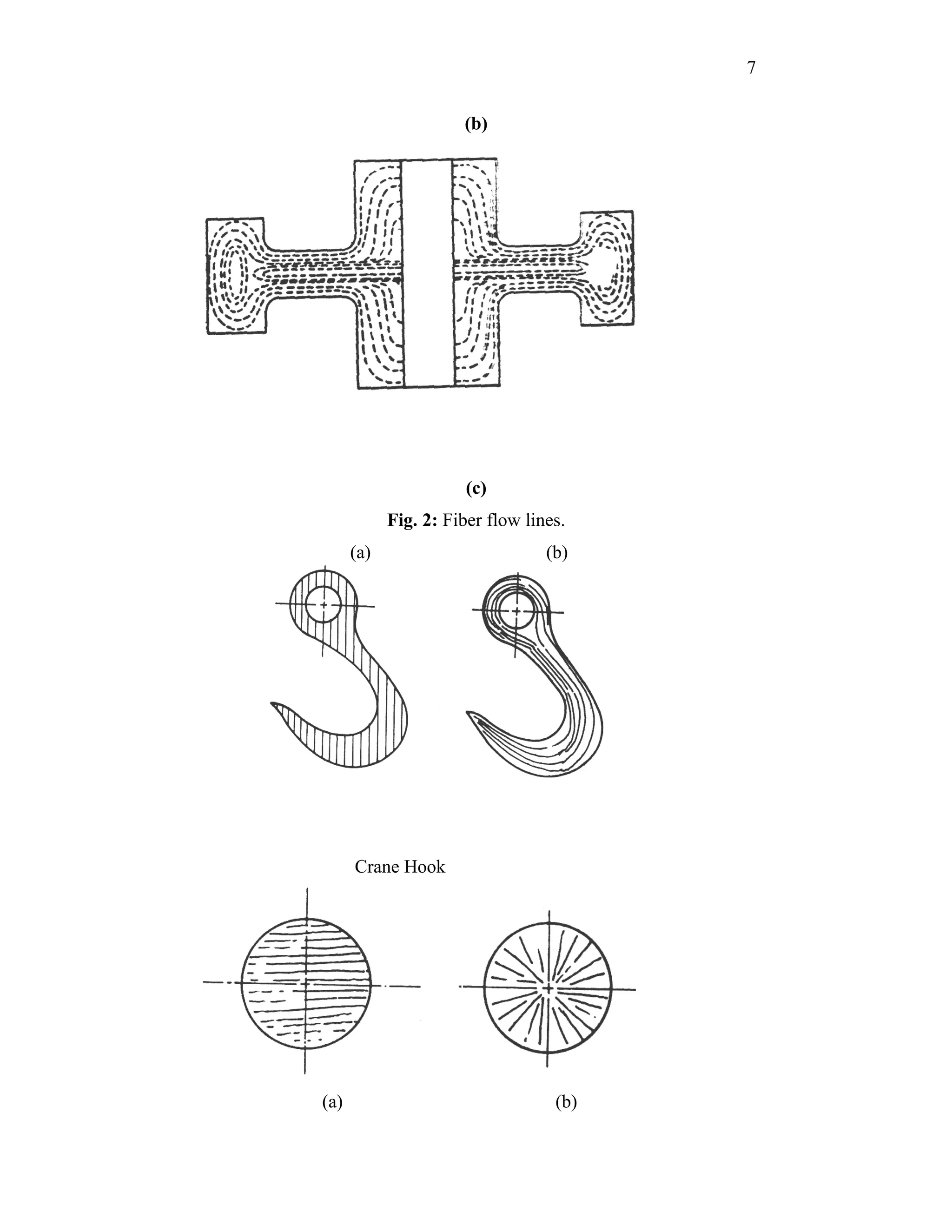

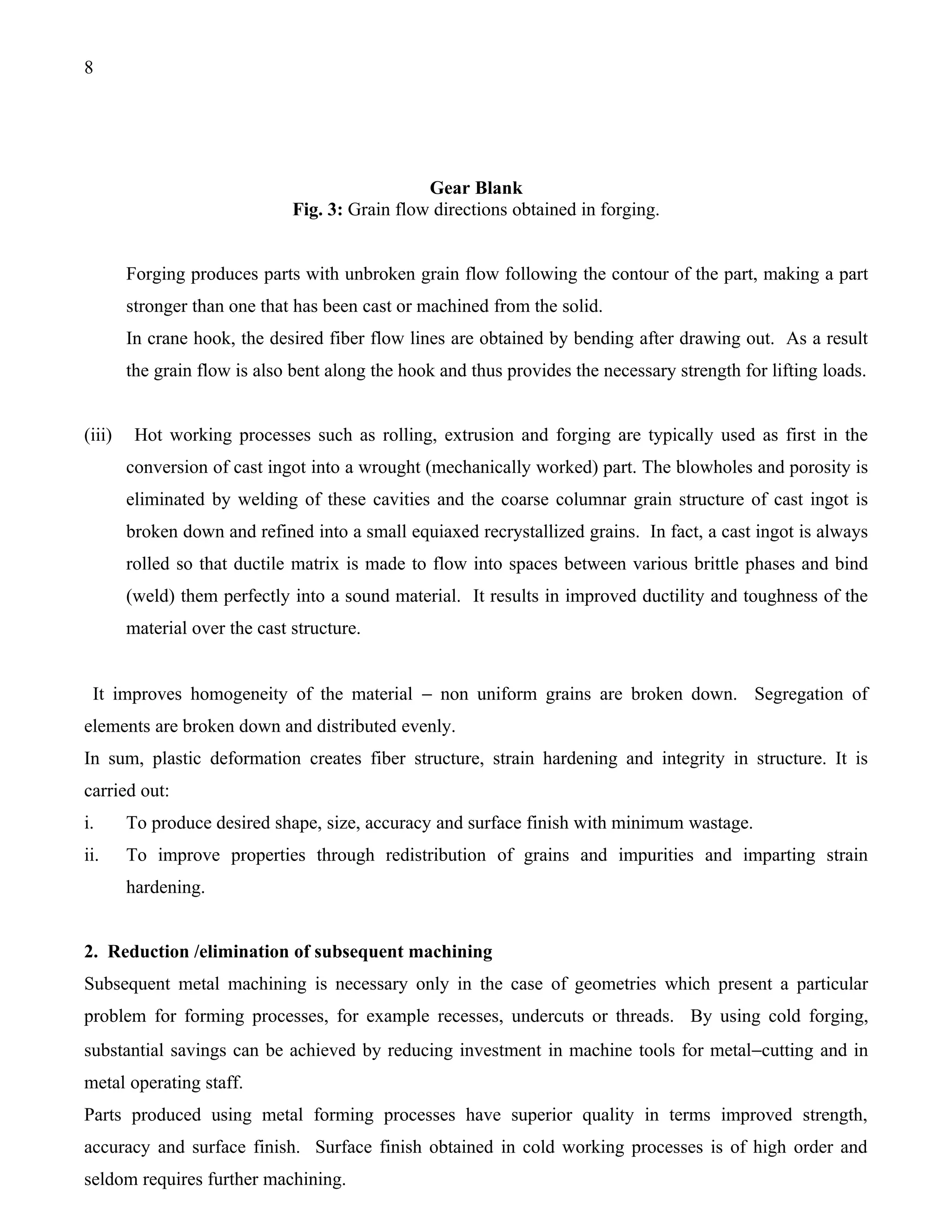

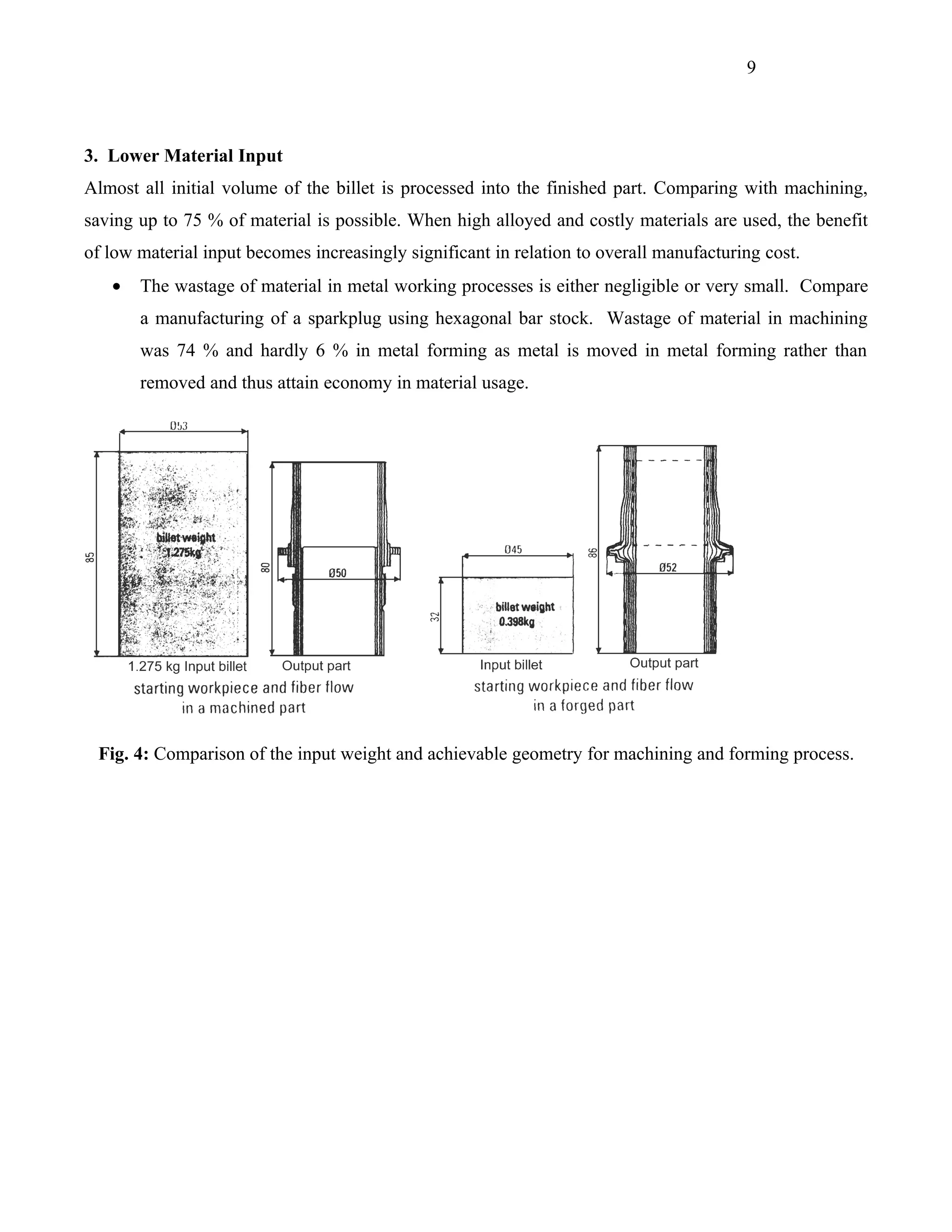

3. Metal forming is advantageous because it produces stronger parts through strain hardening and preferred grain orientation in the direction of loading compared to other manufacturing methods using the same starting material.