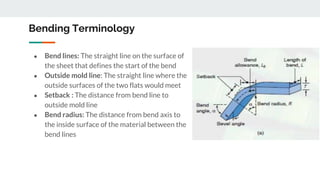

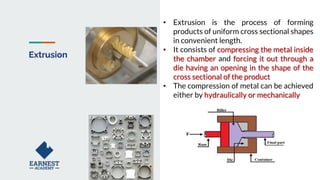

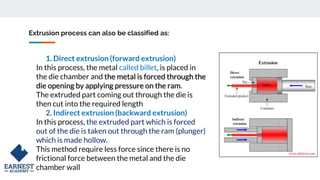

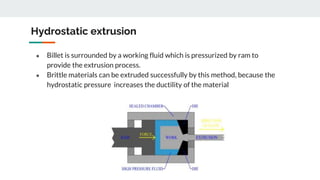

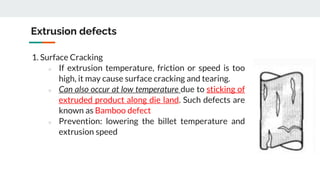

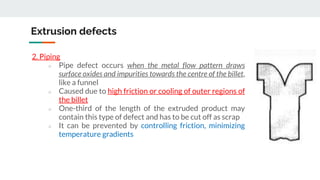

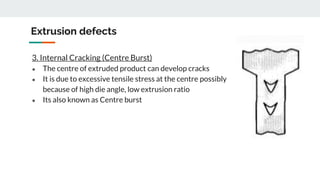

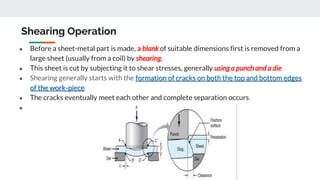

Metal forming processes like extrusion, drawing, bending and shearing are discussed. Extrusion involves compressing metal inside a chamber and forcing it through a die. Direct and indirect extrusion are described. Drawing involves pulling metal through a die to reduce its cross-section. Deep drawing forms cylindrical or box shapes from sheet metal. Shearing uses a punch and die to cut sheet metal. Bending forms shapes by curving sheet metal around a bend line without failure. Defects like surface cracking and piping in extrusion are also summarized.

![Punch force

● The maximum punch force, F, can be estimated from the equation

Where T is the sheet thickness, L is the total length sheared [L= ∏ x D]

(such as the perimeter of a hole), and UTS is the ultimate tensile strength of the

material.](https://image.slidesharecdn.com/ap-classextrusion-231214094757-b02c062c/85/AP-Class-_-Extrusion-pptx-19-320.jpg)