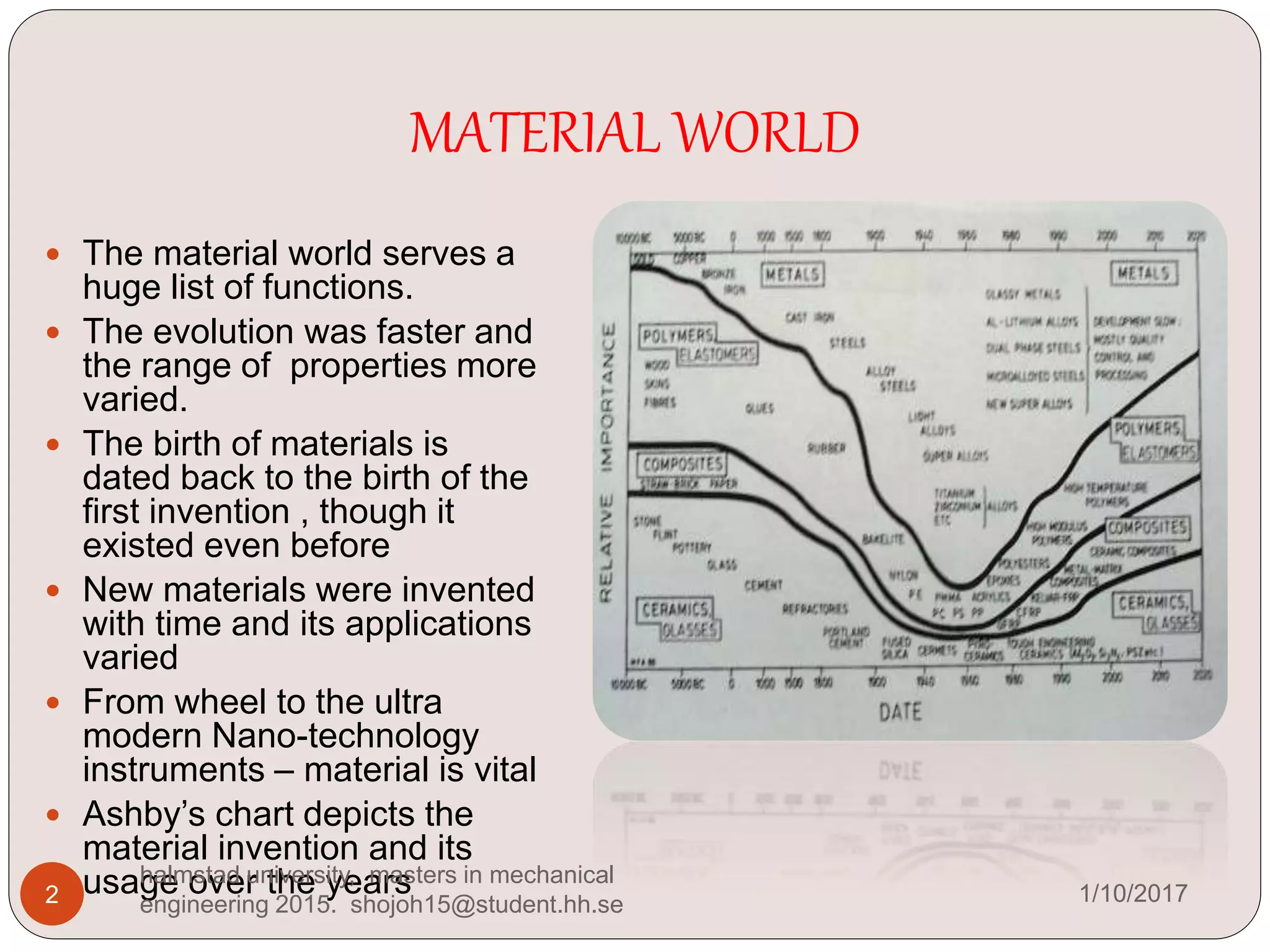

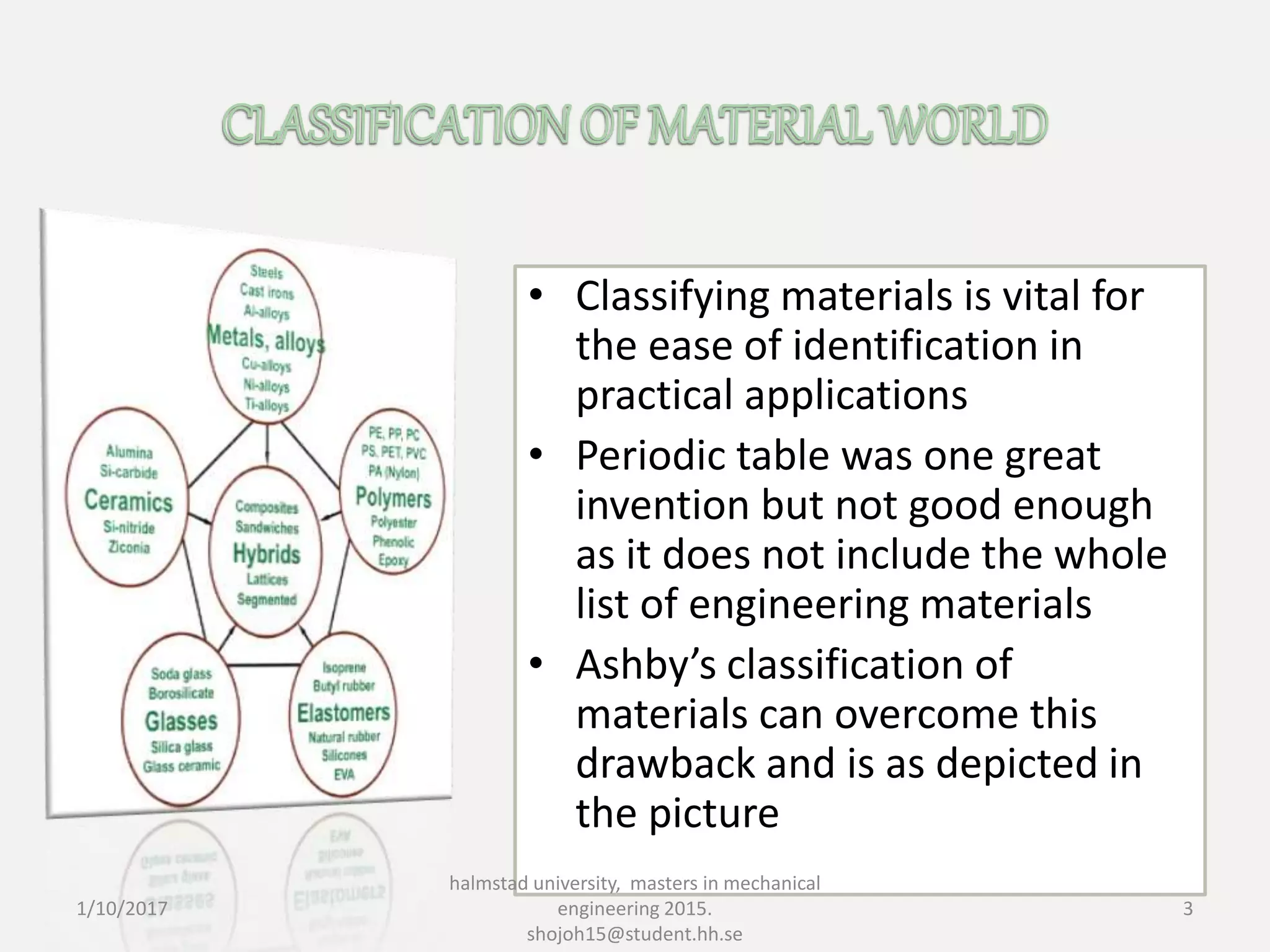

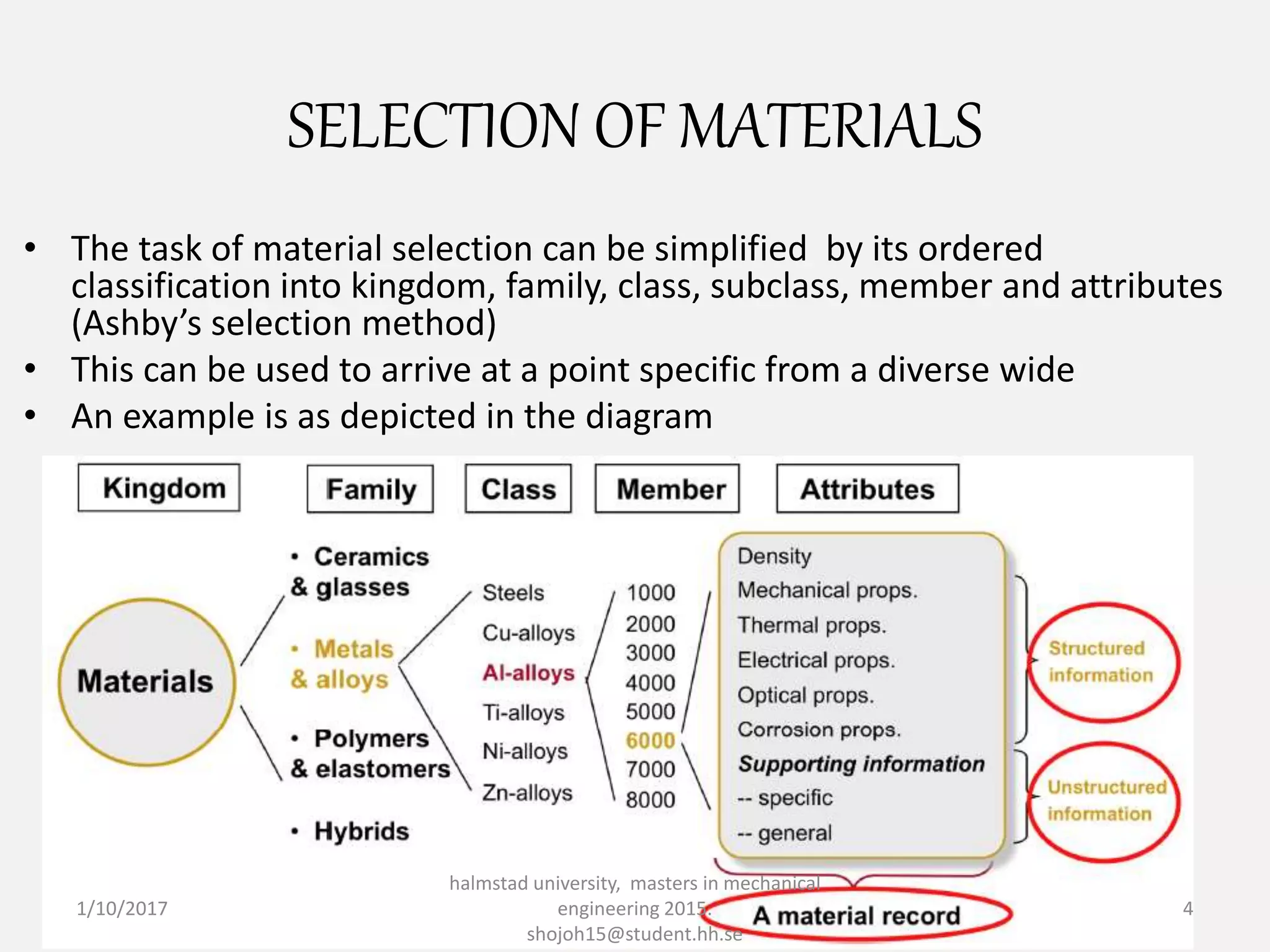

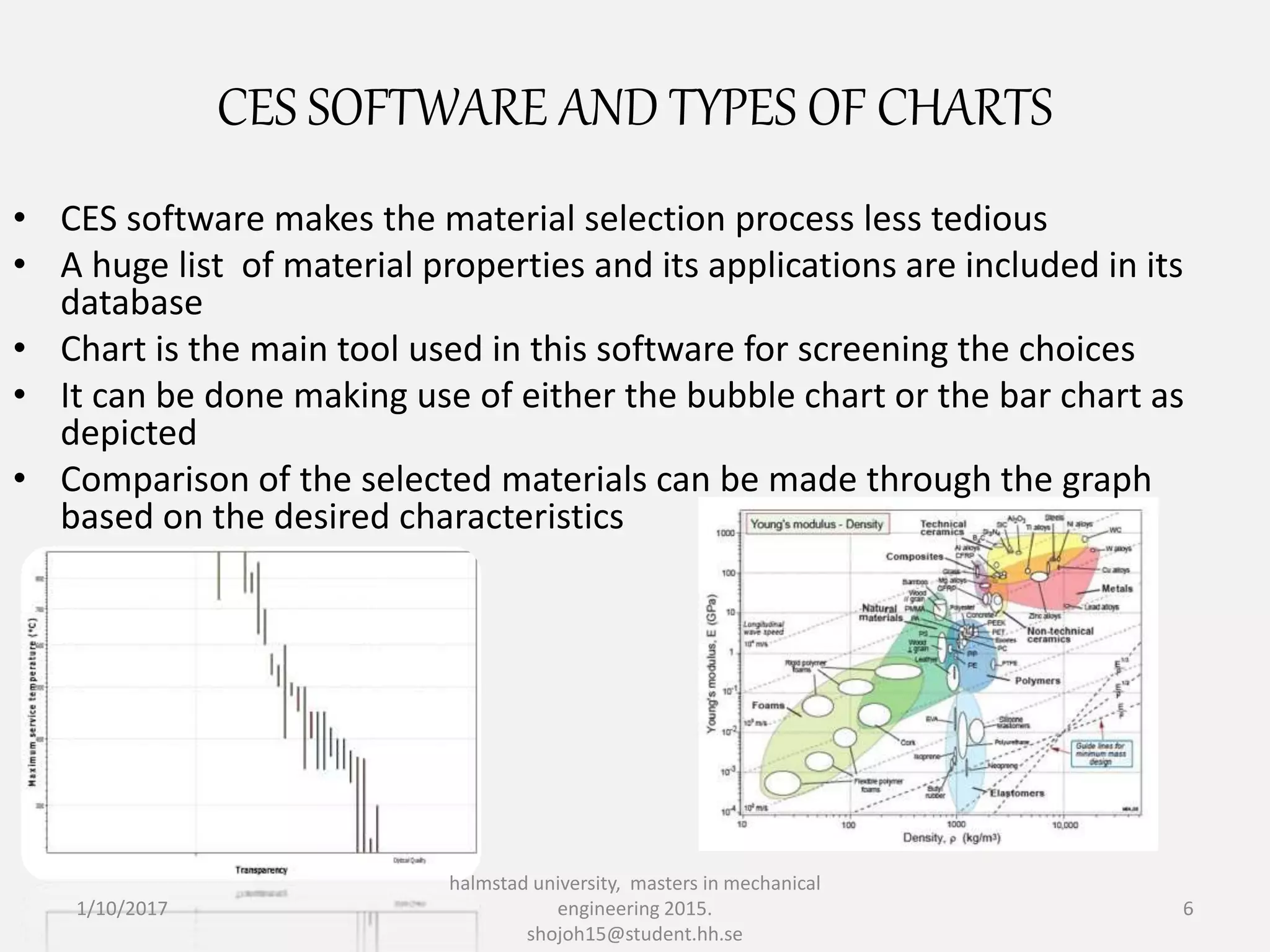

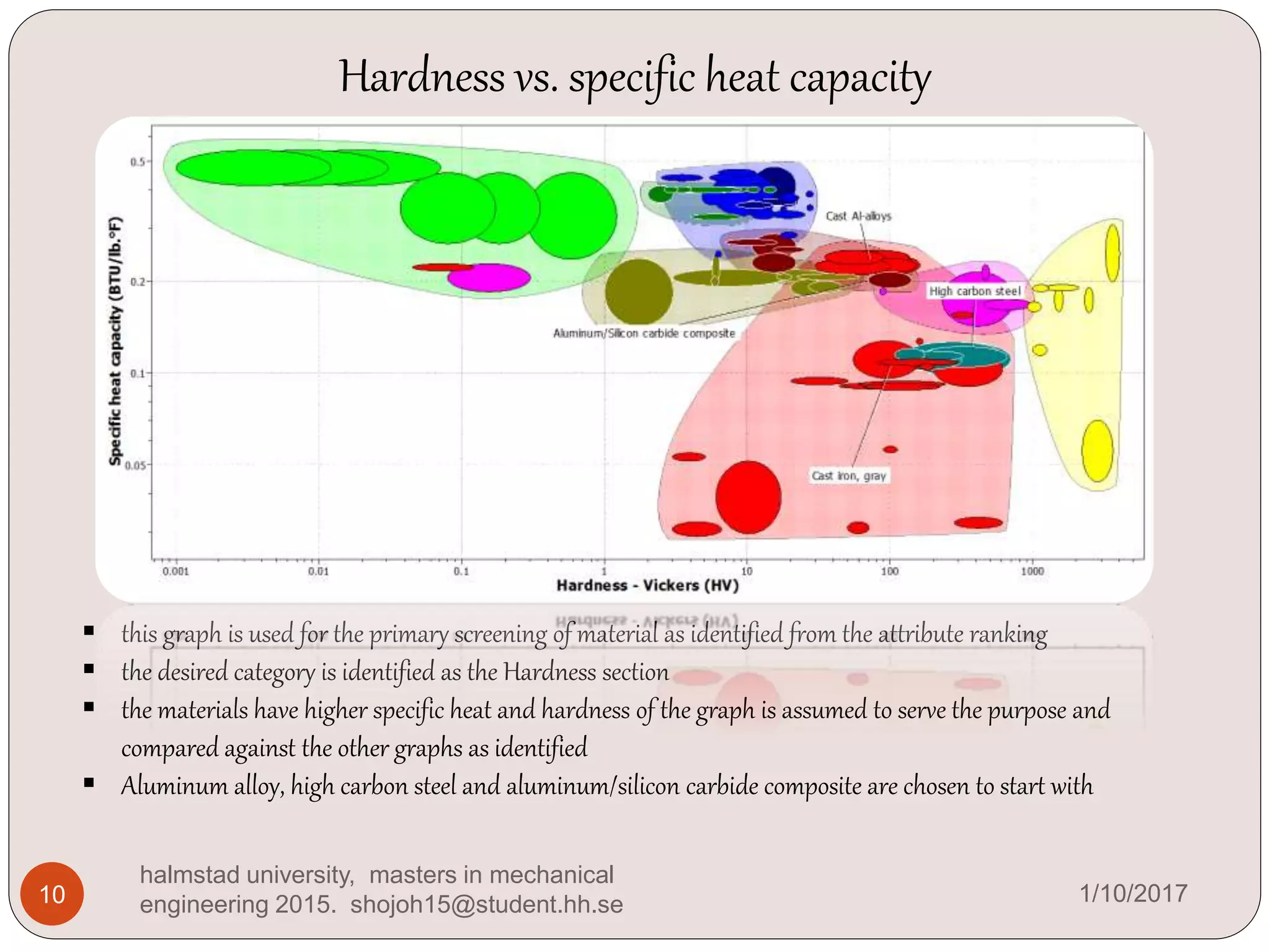

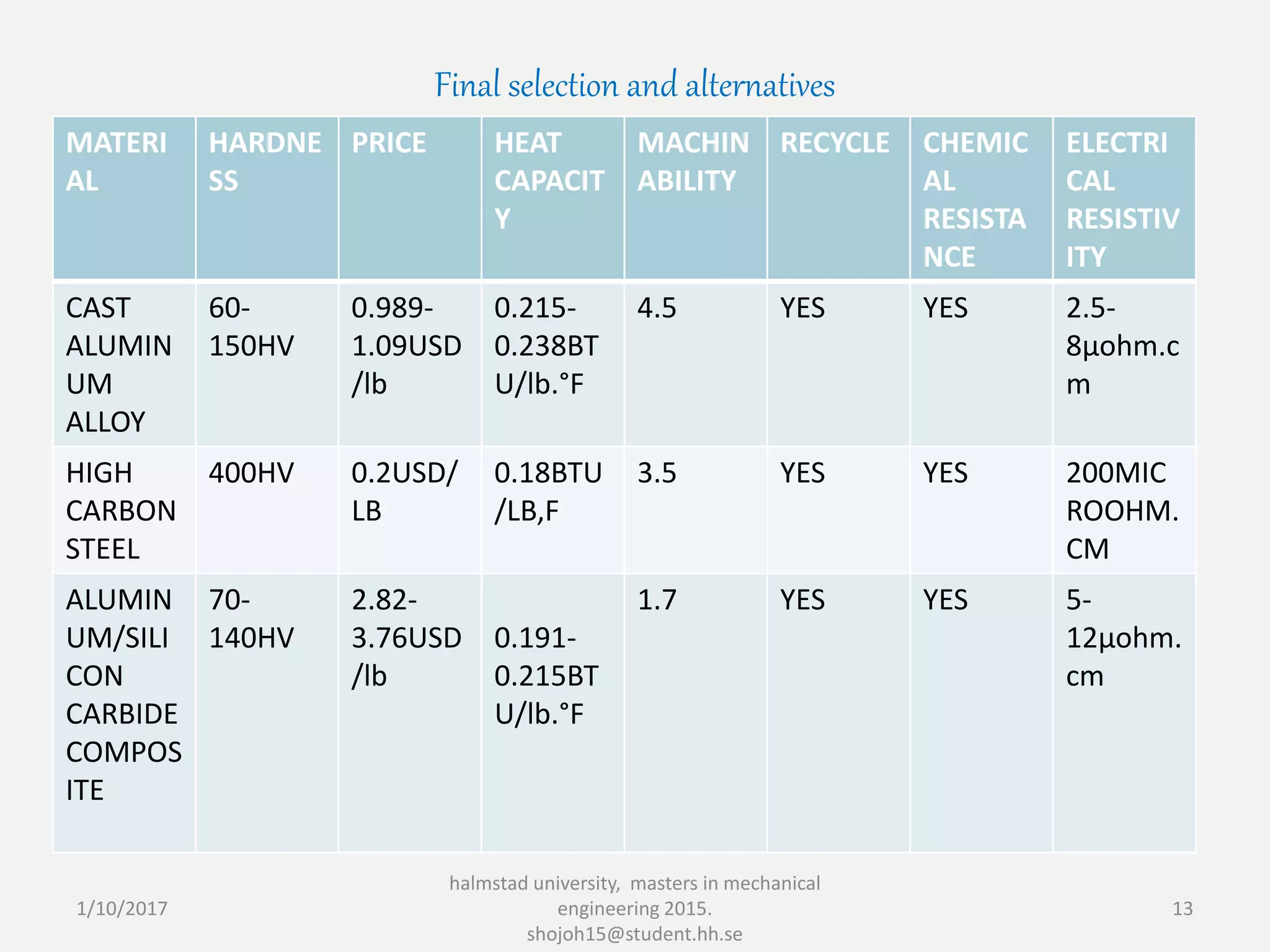

The document discusses material selection for a disc clutch component in a bicycle flywheel project. It describes using Ashby's material selection method and the CES EduPack software to rank material attributes and select materials based on charts plotting hardness vs specific heat, price vs specific heat, and machinability vs price. This led to selecting cast aluminum alloy as it met desired criteria of hardness, price, heat capacity and machinability. High carbon steel and aluminum/silicon carbide composite were identified as alternative materials.