Material selection for different components

•

1 like•731 views

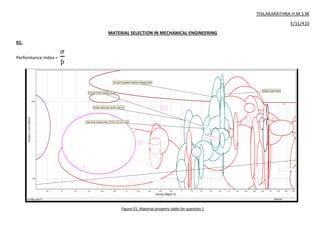

Medium carbon steel is selected for the design because it has a high performance index and low cost. Polytetrafluoroethylene (PTFE) GF1 is selected, despite its high cost, for safety purposes. Wrought Ferritic Stainless Steel is selected because it has a good performance index and good thermal properties. Common hard brick is selected for its low cost, good thermal conduction, and ease of manufacture. Nodular (spheroidal, ductile) Cast Iron is selected for its good performance index and low cost. Low Carbon steel is suitable for designs requiring a material that is low cost, stiff, and strong.

Report

Share

Report

Share

Download to read offline

Recommended

Material Selection and Design Standards

There are over 100,000 engineering materials to choose from. The typical design engineer should have ready access to information on 30 to 60 materials, depending on the range of applications he or she deals with.

Heat Treatment Process

Heat treatment involves heating and cooling metals to alter their internal structure and properties. There are several heat treatment methods for carbon steels including annealing, normalizing, hardening, and tempering. Annealing involves heating steel to high temperatures and slowly cooling to relieve stresses and improve ductility. Normalizing also starts with heating above the critical point but involves air cooling to refine grain size. Hardening greatly increases hardness but causes brittleness, so tempering is used to relieve stresses and improve toughness through controlled reheating.

design and analysis of pressure vessel

This document summarizes a student project on designing and analyzing pressure vessels using conventional and ASME standards methods. It includes:

- Design and analysis of pressure vessels using conventional design, 3D modeling, ANSYS analysis, and ASME code design using PV-Elite software.

- Comparison of designs from conventional versus ASME code methods to determine the safest and most economical approach.

- The project aims to avoid pressure vessel failures and accidents through optimized design and increased safety factors.

Material Selection

The document discusses the materials selection process for choosing an optimal material for a given component. It outlines the general steps as: 1) analyzing performance requirements, 2) developing alternative solutions, 3) evaluating solutions, and 4) deciding on the best solution. Key aspects of the process include identifying material properties needed to meet functional, manufacturing, reliability, and service condition requirements. Multiple potential materials and manufacturing processes are considered to find the best combination that will allow the component to fulfill its intended purpose. Evaluation and selection methods like weighted properties, material indices, and case studies are presented.

Piping components, materials, codes and standards part 1- pipe

The course is focused on four areas: piping components, pipe materials and manufacture, sizes, codes and standards. Applicable piping codes for oil and gas facilities (ISO, B31.3, B31.4, B31.8, etc.), pipe sizing calculations, pipe installation, and materials selection are an integral part of the course. The emphasis is on proper material selection and specification of piping systems.

ASME Section VIII Div 1. design training

This document provides an overview of ASME Boiler and Pressure Vessel Codes. It discusses the objectives and benefits of codes and standards, and describes the ASME Code system and some of its key sections. It focuses on introducing ASME Section VIII Division 1, covering the scope and exclusions of this section. Key topics covered include design requirements, material specifications, fabrication methods, weld joint categories, non-destructive examination methods, and hydrostatic and pneumatic testing requirements.

Production of iron and steel

The document discusses materials science and engineering, specifically focusing on the production of iron and steel. It begins with an introduction to materials science and engineering. It then describes the production process of pig iron, including raw material procurement, blast furnace production, and products. It further discusses various steel production methods like basic oxygen furnace and electric arc furnace production. Continuous casting and different steel products are also outlined. In summary, the document provides an overview of the key industrial processes for producing iron and steel, from raw materials to final products.

Presentation on SECVIII

This document provides an overview and contents of an online course about ASME Section I and Section VIII fundamentals. It includes:

- An introduction to the ASME Boiler and Pressure Vessel Code which contains 12 sections covering various topics like power boilers, materials, pressure vessels, welding qualifications, and piping codes.

- Summaries of the scopes and requirements of key sections like Section I (power boilers), Section VIII (pressure vessels), and the B31 piping codes.

- Information on ASME certification and inspection procedures for pressure equipment.

- A note on converting between imperial and metric units in the ASME codes.

- An introduction to the fundamentals and design requirements

Recommended

Material Selection and Design Standards

There are over 100,000 engineering materials to choose from. The typical design engineer should have ready access to information on 30 to 60 materials, depending on the range of applications he or she deals with.

Heat Treatment Process

Heat treatment involves heating and cooling metals to alter their internal structure and properties. There are several heat treatment methods for carbon steels including annealing, normalizing, hardening, and tempering. Annealing involves heating steel to high temperatures and slowly cooling to relieve stresses and improve ductility. Normalizing also starts with heating above the critical point but involves air cooling to refine grain size. Hardening greatly increases hardness but causes brittleness, so tempering is used to relieve stresses and improve toughness through controlled reheating.

design and analysis of pressure vessel

This document summarizes a student project on designing and analyzing pressure vessels using conventional and ASME standards methods. It includes:

- Design and analysis of pressure vessels using conventional design, 3D modeling, ANSYS analysis, and ASME code design using PV-Elite software.

- Comparison of designs from conventional versus ASME code methods to determine the safest and most economical approach.

- The project aims to avoid pressure vessel failures and accidents through optimized design and increased safety factors.

Material Selection

The document discusses the materials selection process for choosing an optimal material for a given component. It outlines the general steps as: 1) analyzing performance requirements, 2) developing alternative solutions, 3) evaluating solutions, and 4) deciding on the best solution. Key aspects of the process include identifying material properties needed to meet functional, manufacturing, reliability, and service condition requirements. Multiple potential materials and manufacturing processes are considered to find the best combination that will allow the component to fulfill its intended purpose. Evaluation and selection methods like weighted properties, material indices, and case studies are presented.

Piping components, materials, codes and standards part 1- pipe

The course is focused on four areas: piping components, pipe materials and manufacture, sizes, codes and standards. Applicable piping codes for oil and gas facilities (ISO, B31.3, B31.4, B31.8, etc.), pipe sizing calculations, pipe installation, and materials selection are an integral part of the course. The emphasis is on proper material selection and specification of piping systems.

ASME Section VIII Div 1. design training

This document provides an overview of ASME Boiler and Pressure Vessel Codes. It discusses the objectives and benefits of codes and standards, and describes the ASME Code system and some of its key sections. It focuses on introducing ASME Section VIII Division 1, covering the scope and exclusions of this section. Key topics covered include design requirements, material specifications, fabrication methods, weld joint categories, non-destructive examination methods, and hydrostatic and pneumatic testing requirements.

Production of iron and steel

The document discusses materials science and engineering, specifically focusing on the production of iron and steel. It begins with an introduction to materials science and engineering. It then describes the production process of pig iron, including raw material procurement, blast furnace production, and products. It further discusses various steel production methods like basic oxygen furnace and electric arc furnace production. Continuous casting and different steel products are also outlined. In summary, the document provides an overview of the key industrial processes for producing iron and steel, from raw materials to final products.

Presentation on SECVIII

This document provides an overview and contents of an online course about ASME Section I and Section VIII fundamentals. It includes:

- An introduction to the ASME Boiler and Pressure Vessel Code which contains 12 sections covering various topics like power boilers, materials, pressure vessels, welding qualifications, and piping codes.

- Summaries of the scopes and requirements of key sections like Section I (power boilers), Section VIII (pressure vessels), and the B31 piping codes.

- Information on ASME certification and inspection procedures for pressure equipment.

- A note on converting between imperial and metric units in the ASME codes.

- An introduction to the fundamentals and design requirements

Welding of Titanium and Alloys

Welding of Titanium and AlloysSenior Research Fellow, School of Technology, Pandit Deendayal Petroleum University

PPT Includes physical Metallurgy for Titanium and its alloys, Weld ability of them and two welding processes : GTAW and EBW. PPT also describes the Problems with the Welding of Titanium and alloys.Asme viii Div. 1 presentation rev.0

This document provides an overview and introduction to ASME Section VIII Division 1, which establishes rules for the construction of pressure vessels. It discusses the historical context that led to the development of pressure vessel codes, an overview of ASME's codes and standards, key definitions, and the design requirements and considerations specified in Section VIII Division 1. The document covers topics such as material selection, corrosion allowances, minimum thickness requirements, design pressure, and loadings that must be considered in pressure vessel design.

Asme sec viii div 1 icb

This document provides an agenda and overview of a training program on the ASME Boiler and Pressure Vessel Codes. It discusses the objectives of codes and standards, highlights of the ASME Code system including sections I through XI, and introduces Section VIII Division 1 which governs pressure vessels. Key points covered include material requirements, design thickness calculation, weld joint categories, non-destructive testing requirements, and post-weld heat treatment stipulations. The training aims to help participants understand the application and requirements of the ASME pressure vessel codes.

Tank design - powerpoint slides

The document discusses different types of storage tanks including open top tanks, fixed roof tanks, and floating roof tanks. It provides details on supported cone roof tanks, self-supporting fixed roof tanks, single deck and double deck floating roof tanks, and internal floating roof tanks. Key parts and accessories for floating roof tanks are described such as the roof seal system, support legs, roof drain systems, and vents. Standards for storage tanks like API 650 and 653 are also mentioned.

selection of material

material selection based on diffrent properties

prepared by:

pavan narkhede 130120119111

darshit panchal 130120119114

bhautik malviya 130120119094

Material selection

The document discusses selecting eco-friendly materials for bicycle handlebars. It analyzes carbon fiber, bamboo, titanium, stainless steel, and aluminum based on their environmental impact, physical properties, and manufacturability. Mathematical equations are used to determine the optimal thickness for each material to withstand the same bending moments as the original aluminum design. Analysis with the Eco Material Adviser tool shows titanium has the lowest embodied energy and carbon footprint despite its higher strength, allowing for a thinner-walled design using less material. In conclusion, titanium is identified as the most suitable eco-friendly material for the bicycle handlebars.

Ced_ppt

The document discusses the design of vessel heads and closures. It describes various types of heads including flat heads, dished heads, elliptical heads, hemispherical heads, and conical heads. It provides equations for analyzing stress and calculating thickness for flat heads depending on their attachment method to the vessel shell. The maximum stress occurs at the edge of a flat head for a simply supported case and at the center for a clamped case.

Pressure vessel

The document discusses the design, inspection, and repair of pressure vessels. It covers several key topics in 3 paragraphs or less:

Material selection and manufacturing processes are important considerations in pressure vessel design. Pressure vessels are designed to safely contain pressure and withstand operating stresses and temperatures over their design life. Common materials used include steel and aluminum alloys.

Design requirements include calculating stresses, dimensions, and thickness to withstand the internal pressure. Factors like pressure, vessel geometry, material properties, and temperature are considered. Standards like the ASME code provide design procedures and formulas.

Inspection and maintenance are important to determine fitness for service. The maximum allowable working pressure is based on design calculations and limits for each vessel component

ENGINEERING MATERIALS AND THEIR PROPERTIES.pdf

The document discusses engineering materials and their properties. It begins by introducing the importance of materials selection for design engineers. It then classifies engineering materials into metals, alloys, and non-metals. Metals are further divided into ferrous and non-ferrous categories. The document goes on to discuss factors for selecting materials for engineering purposes, as well as the physical and mechanical properties of metals, including properties like strength, stiffness, ductility, and hardness.

Design by Analysis - A general guideline for pressure vessel

This presentation file is provided by Mr. Ghanbari and published under permission.

The presentation gives an introduction and general guideline for pressure vessel design by analysis.

The “design by analysis” procedures are intended to guard against eight possible pressure vessel failure modes by performing a detailed stress analysis of the vessel with the sufficient design factors. The failure modes are:

1.excessive elastic deformation, including elastic instability,

2.excessive plastic deformation,

3.brittle fracture,

4.stress rupture/creep deformation (inelastic),

5.plastic instability - incremental collapse,

6.high strain - low cycle fatigue,

7.stress corrosion, and

8.corrosion fatigue

Most of the “design by analysis” procedures that are given in ASME BPVC relate to designs based on “elastic analysis.”

The design-by-analysis requirements are organized based on protection against the failure modes listed below. The component shall be evaluated for each applicable failure mode. If multiple assessment procedures are provided for a failure mode, only one of these procedures must be satisfied to qualify the design of a component.

a)All pressure vessels within the scope of this Division, irrespective of size or pressure, shall be provided with protection against overpressure in accordance with the requirements of this Part.

b)Protection Against Plastic Collapse – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules.

c)Protection Against Local Failure – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules. It is not necessary to evaluate the local strain limit criterion if the component design is in accordance with Part 4 (i.e. component wall thickness and weld detail per paragraph 4.2).

d)Protection Against Collapse From Buckling – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules and the applied loads result in a compressive stress field.

e)Protection Against Failure From Cyclic Loading – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules and the applied loads are cyclic. In addition, these requirements can also be used to qualify a component for cyclic loading where the thickness and size of the component are established using the design-by-rule requirements of Part 4.

Material Selection

This program develops the concepts for selecting suitable material of construction (MOC) for the industrial applications.

Process Piping.pdf

The document discusses various piping codes and standards. It provides an overview of different ASME B31 codes for different types of piping systems used in power generation, processing plants, transportation of liquids and gases, refrigeration, building services, and slurry transportation. It also summarizes some key aspects covered in ASME B31.3 code for process piping such as scope, exclusions, design pressure, temperature, fluid categories, thickness calculations for pipes, bends, flanges, and other components. The document further discusses welding related topics like preheating, heat treatment, and impact testing requirements.

Static equipment in oil and gas industry

The document provides an introduction and overview of static equipment in the oil and gas industry. It discusses key areas of knowledge required for static equipment engineers, including the main types of static equipment used in oil and gas operations like pressure vessels, heat exchangers, reactors, and storage tanks. The presentation also covers important topics for static equipment such as materials selection and properties, stresses and design codes, and includes a case study on shell and tube heat exchangers. The webinar aims to help engineers in operating companies better understand static equipment.

Hydrogen Induced Cracking

The document summarizes hydrogen induced cracking (HIC) and sulfide stress cracking (SSC), which can occur in materials exposed to hydrogen atoms or hydrogen sulfide. It describes how cracking occurs due to hydrogen diffusion and recombination within metal lattices. Standards for testing material resistance to HIC/SSC are discussed, including test methods involving exposure to hydrogen sulfide-saturated solutions. Cracking is evaluated based on crack length and thickness ratios.

Pressure vessel lecture note ppt

1) The document discusses mechanical design of pressure vessels. It covers classification of pressure vessels and design considerations like stresses and stability.

2) Pressure vessels are classified based on thickness-to-diameter ratio into thin-walled and thick-walled vessels. Common shapes are cylindrical and spherical.

3) Design codes specify guidelines for design, materials, fabrication, inspection and testing of pressure vessels. Stresses like circumferential, longitudinal and shear stresses are derived. Failure theories like maximum principal and shear stresses are discussed.

4) Buckling stability is important for thin-walled vessels under compression. Membrane stress equations are provided for common vessel shapes like cylinders, spheres, cones and ellipsoids.

Pressure vessel

Pressure vessels are designed to safely operate at specific pressures and temperatures. They consist of a cylindrical shell and elliptical or hemispherical heads and are used in applications like reactors, heat exchangers, and storage tanks. Pressure vessels are categorized based on whether they are fired or unfired. Unfired pressure vessels include tanks for storing gases and liquids and are designed according to codes like IS 2825-1969, which specifies design procedures and allows for different material stresses and corrosion allowances depending on the vessel's class. Key considerations in pressure vessel design include operating conditions, materials, dimensions, openings, and supports.

What are Engineering Plastics?

People working in plastics industry come across the word "Engineering plastics" a lot. So we have decided to share some information about this very topic

Heat exchanger - Training course material

This document provides training material on heat exchangers, covering their design, operation, maintenance and enhancement. It begins with classifications of different heat exchanger types including tubular, shell and tube, and plate heat exchangers. It then covers basic design equations using the log mean temperature difference (LMTD) method and number of transfer units (NTU) method. The document provides guidance on thermal design considerations, specification sheets, installation, operation, maintenance including repair vs replacement, and troubleshooting of heat exchangers.

Heat treatment : the best one

This document provides an overview of metal heat treating presented by various individuals. It discusses what metal heat treating is, where it is used, why and how it is done, common heat treating processes and equipment. Specific details covered include commonly heat treated metals, types of heat treating furnaces, importance of protective atmospheres, and different heat treating processes like annealing. The document is intended to educate about key aspects of industrial metal heat treating.

office final ppt [7760835] final update![office final ppt [7760835] final update](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![office final ppt [7760835] final update](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

This document summarizes a final presentation on four months of training in mechanical engineering. It includes topics on the mechanical department, static equipment, pressure vessels, material selection, failures, software used for calculations, and vessel calculation formulas. Diagrams are presented showing examples of horizontal and vertical pressure vessel design in 3D and 2D.

Valve Material selection

This document shows a pressure-temperature rating chart comparing different valve body and seat materials. The rating is determined by whichever component, the body or seat, has the lower temperature and pressure tolerance. Common materials listed include carbon steel, stainless steel, fire-safe epoxy, 316 stainless steel, and Inconel alloy for seats.

ces edupack material selection

The document discusses material selection for a disc clutch component in a bicycle flywheel project. It describes using Ashby's material selection method and the CES EduPack software to rank material attributes and select materials based on charts plotting hardness vs specific heat, price vs specific heat, and machinability vs price. This led to selecting cast aluminum alloy as it met desired criteria of hardness, price, heat capacity and machinability. High carbon steel and aluminum/silicon carbide composite were identified as alternative materials.

More Related Content

What's hot

Welding of Titanium and Alloys

Welding of Titanium and AlloysSenior Research Fellow, School of Technology, Pandit Deendayal Petroleum University

PPT Includes physical Metallurgy for Titanium and its alloys, Weld ability of them and two welding processes : GTAW and EBW. PPT also describes the Problems with the Welding of Titanium and alloys.Asme viii Div. 1 presentation rev.0

This document provides an overview and introduction to ASME Section VIII Division 1, which establishes rules for the construction of pressure vessels. It discusses the historical context that led to the development of pressure vessel codes, an overview of ASME's codes and standards, key definitions, and the design requirements and considerations specified in Section VIII Division 1. The document covers topics such as material selection, corrosion allowances, minimum thickness requirements, design pressure, and loadings that must be considered in pressure vessel design.

Asme sec viii div 1 icb

This document provides an agenda and overview of a training program on the ASME Boiler and Pressure Vessel Codes. It discusses the objectives of codes and standards, highlights of the ASME Code system including sections I through XI, and introduces Section VIII Division 1 which governs pressure vessels. Key points covered include material requirements, design thickness calculation, weld joint categories, non-destructive testing requirements, and post-weld heat treatment stipulations. The training aims to help participants understand the application and requirements of the ASME pressure vessel codes.

Tank design - powerpoint slides

The document discusses different types of storage tanks including open top tanks, fixed roof tanks, and floating roof tanks. It provides details on supported cone roof tanks, self-supporting fixed roof tanks, single deck and double deck floating roof tanks, and internal floating roof tanks. Key parts and accessories for floating roof tanks are described such as the roof seal system, support legs, roof drain systems, and vents. Standards for storage tanks like API 650 and 653 are also mentioned.

selection of material

material selection based on diffrent properties

prepared by:

pavan narkhede 130120119111

darshit panchal 130120119114

bhautik malviya 130120119094

Material selection

The document discusses selecting eco-friendly materials for bicycle handlebars. It analyzes carbon fiber, bamboo, titanium, stainless steel, and aluminum based on their environmental impact, physical properties, and manufacturability. Mathematical equations are used to determine the optimal thickness for each material to withstand the same bending moments as the original aluminum design. Analysis with the Eco Material Adviser tool shows titanium has the lowest embodied energy and carbon footprint despite its higher strength, allowing for a thinner-walled design using less material. In conclusion, titanium is identified as the most suitable eco-friendly material for the bicycle handlebars.

Ced_ppt

The document discusses the design of vessel heads and closures. It describes various types of heads including flat heads, dished heads, elliptical heads, hemispherical heads, and conical heads. It provides equations for analyzing stress and calculating thickness for flat heads depending on their attachment method to the vessel shell. The maximum stress occurs at the edge of a flat head for a simply supported case and at the center for a clamped case.

Pressure vessel

The document discusses the design, inspection, and repair of pressure vessels. It covers several key topics in 3 paragraphs or less:

Material selection and manufacturing processes are important considerations in pressure vessel design. Pressure vessels are designed to safely contain pressure and withstand operating stresses and temperatures over their design life. Common materials used include steel and aluminum alloys.

Design requirements include calculating stresses, dimensions, and thickness to withstand the internal pressure. Factors like pressure, vessel geometry, material properties, and temperature are considered. Standards like the ASME code provide design procedures and formulas.

Inspection and maintenance are important to determine fitness for service. The maximum allowable working pressure is based on design calculations and limits for each vessel component

ENGINEERING MATERIALS AND THEIR PROPERTIES.pdf

The document discusses engineering materials and their properties. It begins by introducing the importance of materials selection for design engineers. It then classifies engineering materials into metals, alloys, and non-metals. Metals are further divided into ferrous and non-ferrous categories. The document goes on to discuss factors for selecting materials for engineering purposes, as well as the physical and mechanical properties of metals, including properties like strength, stiffness, ductility, and hardness.

Design by Analysis - A general guideline for pressure vessel

This presentation file is provided by Mr. Ghanbari and published under permission.

The presentation gives an introduction and general guideline for pressure vessel design by analysis.

The “design by analysis” procedures are intended to guard against eight possible pressure vessel failure modes by performing a detailed stress analysis of the vessel with the sufficient design factors. The failure modes are:

1.excessive elastic deformation, including elastic instability,

2.excessive plastic deformation,

3.brittle fracture,

4.stress rupture/creep deformation (inelastic),

5.plastic instability - incremental collapse,

6.high strain - low cycle fatigue,

7.stress corrosion, and

8.corrosion fatigue

Most of the “design by analysis” procedures that are given in ASME BPVC relate to designs based on “elastic analysis.”

The design-by-analysis requirements are organized based on protection against the failure modes listed below. The component shall be evaluated for each applicable failure mode. If multiple assessment procedures are provided for a failure mode, only one of these procedures must be satisfied to qualify the design of a component.

a)All pressure vessels within the scope of this Division, irrespective of size or pressure, shall be provided with protection against overpressure in accordance with the requirements of this Part.

b)Protection Against Plastic Collapse – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules.

c)Protection Against Local Failure – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules. It is not necessary to evaluate the local strain limit criterion if the component design is in accordance with Part 4 (i.e. component wall thickness and weld detail per paragraph 4.2).

d)Protection Against Collapse From Buckling – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules and the applied loads result in a compressive stress field.

e)Protection Against Failure From Cyclic Loading – these requirements apply to all components where the thickness and configuration of the component is established using design-by-analysis rules and the applied loads are cyclic. In addition, these requirements can also be used to qualify a component for cyclic loading where the thickness and size of the component are established using the design-by-rule requirements of Part 4.

Material Selection

This program develops the concepts for selecting suitable material of construction (MOC) for the industrial applications.

Process Piping.pdf

The document discusses various piping codes and standards. It provides an overview of different ASME B31 codes for different types of piping systems used in power generation, processing plants, transportation of liquids and gases, refrigeration, building services, and slurry transportation. It also summarizes some key aspects covered in ASME B31.3 code for process piping such as scope, exclusions, design pressure, temperature, fluid categories, thickness calculations for pipes, bends, flanges, and other components. The document further discusses welding related topics like preheating, heat treatment, and impact testing requirements.

Static equipment in oil and gas industry

The document provides an introduction and overview of static equipment in the oil and gas industry. It discusses key areas of knowledge required for static equipment engineers, including the main types of static equipment used in oil and gas operations like pressure vessels, heat exchangers, reactors, and storage tanks. The presentation also covers important topics for static equipment such as materials selection and properties, stresses and design codes, and includes a case study on shell and tube heat exchangers. The webinar aims to help engineers in operating companies better understand static equipment.

Hydrogen Induced Cracking

The document summarizes hydrogen induced cracking (HIC) and sulfide stress cracking (SSC), which can occur in materials exposed to hydrogen atoms or hydrogen sulfide. It describes how cracking occurs due to hydrogen diffusion and recombination within metal lattices. Standards for testing material resistance to HIC/SSC are discussed, including test methods involving exposure to hydrogen sulfide-saturated solutions. Cracking is evaluated based on crack length and thickness ratios.

Pressure vessel lecture note ppt

1) The document discusses mechanical design of pressure vessels. It covers classification of pressure vessels and design considerations like stresses and stability.

2) Pressure vessels are classified based on thickness-to-diameter ratio into thin-walled and thick-walled vessels. Common shapes are cylindrical and spherical.

3) Design codes specify guidelines for design, materials, fabrication, inspection and testing of pressure vessels. Stresses like circumferential, longitudinal and shear stresses are derived. Failure theories like maximum principal and shear stresses are discussed.

4) Buckling stability is important for thin-walled vessels under compression. Membrane stress equations are provided for common vessel shapes like cylinders, spheres, cones and ellipsoids.

Pressure vessel

Pressure vessels are designed to safely operate at specific pressures and temperatures. They consist of a cylindrical shell and elliptical or hemispherical heads and are used in applications like reactors, heat exchangers, and storage tanks. Pressure vessels are categorized based on whether they are fired or unfired. Unfired pressure vessels include tanks for storing gases and liquids and are designed according to codes like IS 2825-1969, which specifies design procedures and allows for different material stresses and corrosion allowances depending on the vessel's class. Key considerations in pressure vessel design include operating conditions, materials, dimensions, openings, and supports.

What are Engineering Plastics?

People working in plastics industry come across the word "Engineering plastics" a lot. So we have decided to share some information about this very topic

Heat exchanger - Training course material

This document provides training material on heat exchangers, covering their design, operation, maintenance and enhancement. It begins with classifications of different heat exchanger types including tubular, shell and tube, and plate heat exchangers. It then covers basic design equations using the log mean temperature difference (LMTD) method and number of transfer units (NTU) method. The document provides guidance on thermal design considerations, specification sheets, installation, operation, maintenance including repair vs replacement, and troubleshooting of heat exchangers.

Heat treatment : the best one

This document provides an overview of metal heat treating presented by various individuals. It discusses what metal heat treating is, where it is used, why and how it is done, common heat treating processes and equipment. Specific details covered include commonly heat treated metals, types of heat treating furnaces, importance of protective atmospheres, and different heat treating processes like annealing. The document is intended to educate about key aspects of industrial metal heat treating.

office final ppt [7760835] final update![office final ppt [7760835] final update](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![office final ppt [7760835] final update](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

This document summarizes a final presentation on four months of training in mechanical engineering. It includes topics on the mechanical department, static equipment, pressure vessels, material selection, failures, software used for calculations, and vessel calculation formulas. Diagrams are presented showing examples of horizontal and vertical pressure vessel design in 3D and 2D.

What's hot (20)

Design by Analysis - A general guideline for pressure vessel

Design by Analysis - A general guideline for pressure vessel

Viewers also liked

Valve Material selection

This document shows a pressure-temperature rating chart comparing different valve body and seat materials. The rating is determined by whichever component, the body or seat, has the lower temperature and pressure tolerance. Common materials listed include carbon steel, stainless steel, fire-safe epoxy, 316 stainless steel, and Inconel alloy for seats.

ces edupack material selection

The document discusses material selection for a disc clutch component in a bicycle flywheel project. It describes using Ashby's material selection method and the CES EduPack software to rank material attributes and select materials based on charts plotting hardness vs specific heat, price vs specific heat, and machinability vs price. This led to selecting cast aluminum alloy as it met desired criteria of hardness, price, heat capacity and machinability. High carbon steel and aluminum/silicon carbide composite were identified as alternative materials.

TALAT Lecture 1502: Criteria in Material Selection

This document provides an overview of criteria for material selection. It discusses the need for systematic material selection given the large number of available materials. The objectives are to understand pre-selection, discriminating selection, and optimization in material selection. Intuitive selection methods are highlighted, along with their drawbacks. Systematic selection involves specifying requirements, relating them to material properties, analyzing material groups and specific materials, and optimizing the choice. Material selection is an integral part of design that should be considered at the part level. General guidelines include acting systematically and considering material selection as part of both design and manufacturing.

Webinar - Adobe Photoshop for Advanced Beginners - 2016-03-10

Visit http://www.techsoup.org to learn more about donated technology for nonprofits and libraries!

If you already have an elementary knowledge of Photoshop, this free, one-hour presentation will help you build on your foundation and increase your basic design terminology. This webinar is designed for beginners that have some experience in the program and want to learn more about working with images. TechSoup's content developer, Wes Holing, will demonstrate some advanced fundamentals including:

-- How to work with layers

-- Using the magic wand effectively

-- How to work with and change backgrounds

-- And more!

If you haven't used Adobe Photoshop before, please visit our most recent webinar on Photoshop to prepare for this more advanced event. http://www.techsoup.org/community/events-webinars/adobe-photoshop-for-beginners-2015-12-10

Materialsselection

The document discusses the process of selecting materials for engineering design. It explains that the designer must understand the materials specified by the customer and analyze the product requirements. This includes understanding the product function, intended use, manufacturing methods, and costs. The document uses examples of selecting materials for a bike frame and drink container to illustrate analyzing the product as a system and its individual components. Key factors in materials selection are the required mechanical and physical properties, manufacturability, and costs. Designers can use data sources like textbooks, datasheets, and manufacturers' literature to research materials and select appropriate options using charts comparing properties.

Material selection for manufacturing

This document discusses material selection for manufacturing. It begins by stating that material selection is an important step in product design to minimize costs while meeting performance goals. It then discusses using material selection charts to compare properties like stiffness and density to help choose appropriate materials. The document outlines a four step strategy for material selection: 1) translation to identify design requirements, 2) screening out unsuitable materials, 3) ranking remaining candidates, and 4) seeking additional supporting information. Key material properties like function, constraints, and objectives are defined. Case studies on selecting materials for a bike and drink container are also provided.

Material selection fo aircraft compressor blade

The document discusses material selection considerations for aircraft compressor blades. Key constraints include minimizing mass while withstanding high stresses, having high fracture toughness to tolerate impacts, and operating at temperatures up to 200°C. Titanium alloys currently provide the best balance of properties like strength and toughness relative to density, though carbon fiber reinforced polymers (CFRP) offer lower weight and are being developed. The selection process involves evaluating properties like strength and toughness relative to density for different materials to minimize weight while meeting requirements.

Strain gauge

The document summarizes a student project to create a real-time strain gauge measurement system using microcontrollers. Key aspects included:

- Developing requirements and prototypes for hardware including a printed circuit board and external case to interface with strain gauges.

- Managing the project using Agile SCRUM methodology and collaborating via text, meetings, and project management tools.

- Designing the system architecture including a touch screen GUI, file I/O, and reusing existing IP cores for LCD drivers and audio processing.

- Implementing the system on an Altera DE2 development board connected to strain gauges and facing challenges with hardware acquisition and GUI development.

Material Selection For A Bicycle

The document provides an overview of materials that can be used for bicycle frames including steel, aluminum alloys, titanium, magnesium, and carbon fiber. It discusses the properties of each material such as density, stiffness, yield strength, and fatigue limit. Steel frames are described as strong, inexpensive options that can provide shock absorption but are heavier than other materials. Aluminum alloys are lighter than steel but earlier versions were more prone to fatigue; modern alloys match steel in strength and reliability. Carbon fiber is very light but expensive.

5.material selection criteria

The document discusses material selection criteria for plastics in specific applications. It outlines the process of selecting plastics which involves defining the product purpose, assessing material properties, and considering factors like strength, temperature resistance, wear resistance, degradation resistance, and special properties. The document provides data on various plastic materials and their properties to guide selection. Key properties discussed include tensile strength, fatigue resistance, toughness, corrosion resistance, coefficient of friction, and electrical and thermal properties. Examples are given of applications suited for different plastics based on required characteristics.

Product Design & Process Selection Manufacturing

The document discusses several topics related to product design and manufacturing processes:

1) It describes typical phases of product development including concept development, product planning, engineering, and ramp-up. It also discusses concurrent engineering and design for manufacturability.

2) Quality function deployment and value analysis are presented as ways to design for customers. Break-even analysis is introduced as a method for choosing manufacturing processes.

3) Process flow design and global product strategies are discussed as ways to map how materials move through plants and design products globally. Metrics for measuring product development performance are also listed.

SELECTION OF MATERIAL HANDLING SYSTEM USING MULTI CRITERIA DECISION TECHNIQUE...

The document provides details about selecting a material handling system for Imperial Porcelain Private Limited using multi-criteria decision techniques. It discusses identifying criteria such as product characteristics, conveying speed, cost, etc. and listing alternatives like chain driven roller conveyor, flat belt conveyor, screw conveyor. It proposes using the Analytical Hierarchy Process (AHP), Analytic Network Process (ANP) and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) techniques to rank the alternatives based on the selected criteria and select the most suitable system. The methodology involves developing a decision tree, determining objective factor measures, pairwise comparison matrices and priority vectors to make the final selection.

Viewers also liked (12)

TALAT Lecture 1502: Criteria in Material Selection

TALAT Lecture 1502: Criteria in Material Selection

Webinar - Adobe Photoshop for Advanced Beginners - 2016-03-10

Webinar - Adobe Photoshop for Advanced Beginners - 2016-03-10

SELECTION OF MATERIAL HANDLING SYSTEM USING MULTI CRITERIA DECISION TECHNIQUE...

SELECTION OF MATERIAL HANDLING SYSTEM USING MULTI CRITERIA DECISION TECHNIQUE...

Similar to Material selection for different components

Design Project - Electric Furnace for Steel Making

The document summarizes a student design project to improve the process of making stainless steel using an electric arc furnace. It discusses the current electric furnace operation, literature reviewing different steel making methods, materials selection for the furnace roof, and two proposed designs - incorporating vacuum oxygen decarburization into the furnace and installing electromagnetic stirrers along the furnace sides for better melt homogenization. Recommendations are made to improve heat exchange, refractory materials, and refractory cooling.

Optimization of spheroidized annealing process parameters on AISI 10B21 steel...

This document analyzes the optimization of spheroidized annealing process parameters on AISI 10B21 steel wire using the Taguchi approach. It aims to improve the mechanical properties of steel wires for cold forming of screws. Three annealing parameters - temperature, heating time, and cooling temperature - were tested at different levels using an orthogonal array experiment. Results found that annealing temperature was the most significant factor affecting tensile strength and ductility. The optimum conditions were determined to be 725°C temperature, 7 hours heating time, and 500°C cooling temperature to achieve a tensile strength of 40.94 kgf/mm2 and ductility of 26.03% while minimizing hardness. This provides a reference for wire manufacturers to improve

IRJET-Effect of Chemical Composition on Total Carbon Equivalent in Grey Iron ...

The document summarizes research into the effect of chemical composition on the total carbon equivalent and properties of grey iron castings. It discusses how the carbon equivalent value is calculated based on carbon, silicon, and phosphorus content. Experimental results showed that a carbon equivalent of 4.3 produced Type A graphite flakes and maximum tensile strength for a 15mm diameter bar. A casting trial produced an impeller with the desired properties and microstructure using a chemical composition from the experiment with a carbon equivalent of 4.3. In conclusion, adopting this chemical composition promoted the desired Type A graphite formation.

Analysis and Improvement of Distortion of Lathe Machine Main Spindle

This document analyzes the distortion of lathe machine main spindles and proposes improvements through a sub-zero heat treatment process. It begins by describing how lathe spindles made of En353 steel undergo distortion from high stresses during conventional heat treatment. The document then details the conventional heat treatment process and proposes applying a sub-zero treatment instead. Samples are tested with microstructures analyzed and hardness measured. Results show the sub-zero treated sample has lower retained austenite, higher hardness, and improved dimensional stability compared to conventional treatment. The document concludes the sub-zero treatment is an effective way to reduce distortion in lathe machine main spindles.

Basics of Engineering Materials.pptx

This presentation gives the basics of engineering materials used in the power plant industry. It also gives the basics of the heat treatment processes and application of materials.

Different steels are majorly shown in the presentation. It starts from carbon steel and goes to advanced high-temperature materials.

Different heat treatments are also discussed. The property changes are observed after heat treatments are given.

Why use duplex ss for storage tanks

This document discusses the benefits of using duplex stainless steel for storage tanks compared to other stainless steel grades. Duplex stainless steel offers high strength, corrosion resistance, and stress corrosion cracking resistance, allowing for thinner material thickness and reduced costs. It maintains these properties with a lower nickel content and stable pricing. The document provides examples of duplex stainless steel grades used in existing storage tank projects for applications like acids, oils, and slurries. It also outlines international standards for tank design and compares required wall thickness between duplex and other stainless steel grades.

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Abstract: Cold-formed steel members have been widely used in residential, industrial and commercial

buildings as primary load bearing structural elements due to their advantages such as higher strength to

weight ratio over the other structural materials such as hot-rolled steel, timber and concrete. However,

they are susceptible to various buckling modes including local and distortional buckling. Fire safety

design of building structures has received greater attention in recent times as fire events can cause loss

of property and lives. Therefore it is essential to understand the fire performance of light gauge coldformed

steel structures under fire conditions. The buckling behavior of cold-formed steel compression

members under fire conditions is not well investigated yet and hence there is a lack of knowledge on the

fire performance of cold-formed steel compression members. Therefore, this paper deals with behavior

of cold formed steel compression member under fire and to analyze the effect of fire on critical buckling

load of compression member. Eigen value analysis for Lipped channel sections made of various

thicknesses and both low and high strength steels was carried out through finite element method. The

ultimate load carrying capacity results from experimental investigation and finite element analyses were

then compared

Optimization of Hybrid Aluminium Metal Matrix Composite Through Taguchi Method

This document summarizes an experiment that used the Taguchi method to optimize machining parameters for an aluminium metal matrix composite reinforced with 5% boron carbide and 6% fly ash during electrical discharge machining. An L9 orthogonal array was used to test combinations of current, pulse on time, and pulse off time. The responses of metal removal rate and surface roughness were measured. Signal-to-noise ratios were calculated and analyzed to determine that current had the greatest influence on both metal removal rate and surface roughness, followed by pulse on time and then pulse off time.

FRACTOGRAPHY OF CRYOGENIC CHILL CASTED ASTM A 494 M GRADE NICKEL ALLOY METAL ...

ASTM A 494 M grade Ni–Garnet composites containing four different weight percentages 3%, 6%,9% and 12% of Garnet samples have been fabricated by using cryogenically cooled copper chill stir

casting method. Effects of volume percent of Garnet particles on tensile strength, and fracture surfacesof Nickel Garnet composites have been investigated. The highest tensile strength was achieved in the specimen containing 9 Wt. % garnet produced with 25 mm chill thickness which shows an increase of14% in comparison to the no chill cast reinforced alloy. Microscopic investigations of fracture surfacesrevealed that fracture in a brittle manner with little or no necking happening. By increasing garnetcontent and chill thickness, the composites fracture goes in a more severely brittle manner. The fracturebehavior of the composites was altered significantly by the presence of garnet particles and the crack

propagation through the matrix and the reinforcing particle clusters resulted in the final fracture.

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

This document summarizes an experiment that analyzed the effect of machining parameters on surface roughness, cutting temperature, and forces when turning an aluminum metal matrix composite (MMC) with tungsten carbide inserts. The MMC was fabricated via stir casting and machined using different cutting speeds, feeds, and depths of cut. Results showed that surface roughness decreased with increasing speed and decreasing feed and depth of cut. Cutting temperature was highest at medium speeds and feeds. Aluminum inserts produced better surface finish and lower temperatures than steel inserts but steel inserts generated lower cutting forces. The experiment aimed to determine optimal machining parameters for the composite.

IRJET- A Study on Effect of SIC on Mechanical Properties of Aluminium 8011 Me...

1) The document studies the effect of silicon carbide (SiC) particles on the mechanical properties of an aluminium 8011 metal matrix composite.

2) Samples containing 3%, 5%, and 7% SiC by weight were produced using stir casting. They were then tested for hardness, tensile strength, and flexural strength.

3) The results showed that hardness, tensile strength, and flexural strength all increased with higher SiC content, with tensile strength increasing up to 5% SiC. Ductility decreased with more SiC due to its strengthening effect.

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

The document discusses the effect of tempering process on EN-24 steel alloy. It describes conducting experiments to evaluate the mechanical properties like hardness, tensile strength, yield strength, elongation and reduction in area of EN-24 steel specimens before and after subjecting them to different tempering temperatures ranging from 300 to 700 degrees Celsius. The results showed that hardness, tensile strength and yield strength decreased with increasing tempering temperature, while elongation, reduction in area and toughness increased significantly. Microstructural analysis using an optical microscope was also performed to examine the phase transformations occurring during the tempering process.

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

The document discusses the effect of tempering process on EN-24 steel alloy. It describes conducting experiments to evaluate the mechanical properties like hardness, tensile strength, yield strength, elongation and reduction in area of EN-24 steel specimens before and after subjecting them to different tempering temperatures between 300-700 degrees Celsius. Microstructural analysis using optical microscope was also performed to examine the phase transformations occurring during tempering. The results showed that hardness, tensile strength and yield strength decreased with increasing tempering temperature, while elongation, reduction in area and toughness increased significantly.

An assessment of the microstraft

The International Institute for Science, Technology and Education (IISTE). Science, Technology and Medicine Journals Call for Academic Manuscripts

Materials Properties

This document contains the answers to review questions for Assignment 01 on Materials of Manufacture submitted by group members Asad Ali, Syed Ali, Azeem Khan, Usman Ayub, and Usman Munawar. It includes answers on topics such as ductility, stress-strain curves, brittle vs ductile fracture, properties and applications of various materials including steel grades, aluminum, cast irons, tungsten, and nanomaterials. Example products discussed include a carpenter's hammer head and residential doorknob. The hammer would be made of heat-treated high carbon steel for strength and durability, while doorknobs are commonly made of brass which is easy to form and has an attractive golden color

Austenitics

This document provides an overview of the history and development of austenitic stainless steels, including high performance austenitic stainless steels (HPASS). It discusses how new steelmaking technologies in the 1970s allowed for the development of HPASS grades with improved alloying control and performance. Some of the first HPASS grades developed included 904L and AL-6X, aimed for applications requiring resistance to reducing acids and seawater, respectively. Demand for cost-effective alloys for energy and environmental industries further drove development of newer HPASS grades with very high pitting resistance, such as 654 SMO.

Design considerations and engineering materials

This document presents information on design considerations and engineering materials for machine elements. It discusses various factors that must be considered in machine design like strength, cost, manufacturability. It also covers material properties and how heat treatment can be used to modify properties. Different types of steels are described based on their mechanical properties, chemical composition, and applications like tool steels. The standardization process and preferred number series are also introduced.

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Cold-formed steel members have been widely used in residential, industrial and commercial

buildings as primary load bearing structural elements due to their advantages such as higher strength to

weight ratio over the other structural materials such as hot-rolled steel, timber and concrete. However,

they are susceptible to various buckling modes including local and distortional buckling. Fire safety

design of building structures has received greater attention in recent times as fire events can cause loss

of property and lives. Therefore it is essential to understand the fire performance of light gauge coldformed

steel structures under fire conditions. The buckling behavior of cold-formed steel compression

members under fire conditions is not well investigated yet and hence there is a lack of knowledge on the

fire performance of cold-formed steel compression members. Therefore, this paper deals with behavior

of cold formed steel compression member under fire and to analyze the effect of fire on critical buckling

load of compression member. Eigen value analysis for Lipped channel sections made of various

thicknesses and both low and high strength steels was carried out through finite element method. The

ultimate load carrying capacity results from experimental investigation and finite element analyses were

then compared.

FABRICATION OF LM6/B4C/GR ALUMINIUM METAL MATRIX COMPOSITE

This work deals with fabricating or producing aluminum based metal matrix composite and then studying its mechanical properties such as tensile strength, hardness and wear behavior of produced test specimen. In this conditions Aluminum Alloy (LM6) –Boron Carbide and graphite metal matrix composite were fabricated by liquid metallurgy technique with different particulate weight fraction ( Gr 2% and B4C 3 %, 5%). Mechanical properties such as hardness test and compression strength are determined and tribological behavior of the composite is studied using wear test. The composite were characterized by Hardness and tensile strength tests. With the increase the amount of boron carbide, the density of the composite decreased whereas the hardness is increased. The tensile strength of the composite was increased with increase in the weight percentage of the boron carbide and Gr in the composite.

Experimental and Microstructural Analysis of TIG and MIG Welding on Dissimila...

In the modern era, most of the industries have a high demand of light weight, high strength structures with desired product properties which depend on the joining of dissimilar materials for manufacturing.

In TIG welding tungsten electrode is placed centrally in the torch. During the inert gas supplied through the annular space between torch and electrode, the filler material was supplied using a separate rod and shielding undertaken by covering the weld zone with a blanket of gases (Argon, Helium) which prevent the exposure of weld metal to oxygen and hydrogen of the air.

In MIG welding, the arc is struck between the work piece and the wire, which act as electrode and filler material, the arc and weld pool were shielded by inert gas. Depending upon the work material, the shielding gas may be argon, helium and carbon dioxide. In this case, the bare metal electrode (consumable electrode) in the form of continuous wire is fed through welding torch with the help of electrical motor and feed rolls.

Mild Steels are the carbon steels which generally contain less than about 0.60-1.4% wt of Carbon. The alloy of Mild Steel with Chromium, Magnesium, Vanadium, tungsten and Molybdenum are used as Knives, Razors, Cutting tool, dies, hacksaw blades and crankshaft. They typically have a yield strength of 430–585MPa (62–85 Ksi), tensile strengths 605-780 MPa (88–113 Ksi), and a ductility of 33–19%EL.

The stainless steels are highly resistant to corrosion in a variety of environments, especially ambient atmosphere. Their predominant alloying element is chromium; a concentration of at least 11 wt% Cr is required. They typically consist a yield strength of 205 MPa (30ksi) to 1650Mpa (240 Ksi), tensile strengths between 380 and 1790 MPa (55 to 260 Ksi), and a ductility of 20 to 40%EL. A wide range of mechanical properties combines with excellent resistance to corrosion making stainless steels very versatile in their applicability. Equipment employed for these steels includes gas turbines, high-temperature steam boilers, heat-treating furnaces, aircraft, missiles, and nuclear power–generating units.

Similar to Material selection for different components (20)

Design Project - Electric Furnace for Steel Making

Design Project - Electric Furnace for Steel Making

Optimization of spheroidized annealing process parameters on AISI 10B21 steel...

Optimization of spheroidized annealing process parameters on AISI 10B21 steel...

IRJET-Effect of Chemical Composition on Total Carbon Equivalent in Grey Iron ...

IRJET-Effect of Chemical Composition on Total Carbon Equivalent in Grey Iron ...

Analysis and Improvement of Distortion of Lathe Machine Main Spindle

Analysis and Improvement of Distortion of Lathe Machine Main Spindle

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Optimization of Hybrid Aluminium Metal Matrix Composite Through Taguchi Method

Optimization of Hybrid Aluminium Metal Matrix Composite Through Taguchi Method

FRACTOGRAPHY OF CRYOGENIC CHILL CASTED ASTM A 494 M GRADE NICKEL ALLOY METAL ...

FRACTOGRAPHY OF CRYOGENIC CHILL CASTED ASTM A 494 M GRADE NICKEL ALLOY METAL ...

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

IRJET- A Study on Effect of SIC on Mechanical Properties of Aluminium 8011 Me...

IRJET- A Study on Effect of SIC on Mechanical Properties of Aluminium 8011 Me...

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

FABRICATION OF LM6/B4C/GR ALUMINIUM METAL MATRIX COMPOSITE

FABRICATION OF LM6/B4C/GR ALUMINIUM METAL MATRIX COMPOSITE

Experimental and Microstructural Analysis of TIG and MIG Welding on Dissimila...

Experimental and Microstructural Analysis of TIG and MIG Welding on Dissimila...

Recently uploaded

Accident detection system project report.pdf

The Rapid growth of technology and infrastructure has made our lives easier. The

advent of technology has also increased the traffic hazards and the road accidents take place

frequently which causes huge loss of life and property because of the poor emergency facilities.

Many lives could have been saved if emergency service could get accident information and

reach in time. Our project will provide an optimum solution to this draw back. A piezo electric

sensor can be used as a crash or rollover detector of the vehicle during and after a crash. With

signals from a piezo electric sensor, a severe accident can be recognized. According to this

project when a vehicle meets with an accident immediately piezo electric sensor will detect the

signal or if a car rolls over. Then with the help of GSM module and GPS module, the location

will be sent to the emergency contact. Then after conforming the location necessary action will

be taken. If the person meets with a small accident or if there is no serious threat to anyone’s

life, then the alert message can be terminated by the driver by a switch provided in order to

avoid wasting the valuable time of the medical rescue team.

AI-Based Home Security System : Home security

Home security is of paramount importance in today's world, where we rely more on technology, home

security is crucial. Using technology to make homes safer and easier to control from anywhere is

important. Home security is important for the occupant’s safety. In this paper, we came up with a low cost,

AI based model home security system. The system has a user-friendly interface, allowing users to start

model training and face detection with simple keyboard commands. Our goal is to introduce an innovative

home security system using facial recognition technology. Unlike traditional systems, this system trains

and saves images of friends and family members. The system scans this folder to recognize familiar faces

and provides real-time monitoring. If an unfamiliar face is detected, it promptly sends an email alert,

ensuring a proactive response to potential security threats.

Blood finder application project report (1).pdf

Blood Finder is an emergency time app where a user can search for the blood banks as

well as the registered blood donors around Mumbai. This application also provide an

opportunity for the user of this application to become a registered donor for this user have

to enroll for the donor request from the application itself. If the admin wish to make user

a registered donor, with some of the formalities with the organization it can be done.

Specialization of this application is that the user will not have to register on sign-in for

searching the blood banks and blood donors it can be just done by installing the

application to the mobile.

The purpose of making this application is to save the user’s time for searching blood of

needed blood group during the time of the emergency.

This is an android application developed in Java and XML with the connectivity of

SQLite database. This application will provide most of basic functionality required for an

emergency time application. All the details of Blood banks and Blood donors are stored

in the database i.e. SQLite.

This application allowed the user to get all the information regarding blood banks and

blood donors such as Name, Number, Address, Blood Group, rather than searching it on

the different websites and wasting the precious time. This application is effective and

user friendly.

Applications of artificial Intelligence in Mechanical Engineering.pdf

Historically, mechanical engineering has relied heavily on human expertise and empirical methods to solve complex problems. With the introduction of computer-aided design (CAD) and finite element analysis (FEA), the field took its first steps towards digitization. These tools allowed engineers to simulate and analyze mechanical systems with greater accuracy and efficiency. However, the sheer volume of data generated by modern engineering systems and the increasing complexity of these systems have necessitated more advanced analytical tools, paving the way for AI.

AI offers the capability to process vast amounts of data, identify patterns, and make predictions with a level of speed and accuracy unattainable by traditional methods. This has profound implications for mechanical engineering, enabling more efficient design processes, predictive maintenance strategies, and optimized manufacturing operations. AI-driven tools can learn from historical data, adapt to new information, and continuously improve their performance, making them invaluable in tackling the multifaceted challenges of modern mechanical engineering.

Data Driven Maintenance | UReason Webinar

Discover the latest insights on Data Driven Maintenance with our comprehensive webinar presentation. Learn about traditional maintenance challenges, the right approach to utilizing data, and the benefits of adopting a Data Driven Maintenance strategy. Explore real-world examples, industry best practices, and innovative solutions like FMECA and the D3M model. This presentation, led by expert Jules Oudmans, is essential for asset owners looking to optimize their maintenance processes and leverage digital technologies for improved efficiency and performance. Download now to stay ahead in the evolving maintenance landscape.

Prediction of Electrical Energy Efficiency Using Information on Consumer's Ac...

Energy efficiency has been important since the latter part of the last century. The main object of this survey is to determine the energy efficiency knowledge among consumers. Two separate districts in Bangladesh are selected to conduct the survey on households and showrooms about the energy and seller also. The survey uses the data to find some regression equations from which it is easy to predict energy efficiency knowledge. The data is analyzed and calculated based on five important criteria. The initial target was to find some factors that help predict a person's energy efficiency knowledge. From the survey, it is found that the energy efficiency awareness among the people of our country is very low. Relationships between household energy use behaviors are estimated using a unique dataset of about 40 households and 20 showrooms in Bangladesh's Chapainawabganj and Bagerhat districts. Knowledge of energy consumption and energy efficiency technology options is found to be associated with household use of energy conservation practices. Household characteristics also influence household energy use behavior. Younger household cohorts are more likely to adopt energy-efficient technologies and energy conservation practices and place primary importance on energy saving for environmental reasons. Education also influences attitudes toward energy conservation in Bangladesh. Low-education households indicate they primarily save electricity for the environment while high-education households indicate they are motivated by environmental concerns.

一比一原版(uofo毕业证书)美国俄勒冈大学毕业证如何办理

原版一模一样【微信:741003700 】【(uofo毕业证书)美国俄勒冈大学毕业证成绩单】【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(uofo毕业证书)美国俄勒冈大学毕业证【微信:741003700 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(uofo毕业证书)美国俄勒冈大学毕业证【微信:741003700 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(uofo毕业证书)美国俄勒冈大学毕业证【微信:741003700 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(uofo毕业证书)美国俄勒冈大学毕业证【微信:741003700 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

一比一原版(uoft毕业证书)加拿大多伦多大学毕业证如何办理

原版一模一样【微信:741003700 】【(uoft毕业证书)加拿大多伦多大学毕业证成绩单】【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】外观非常简单,由纸质材料制成,上面印有校徽、校名、毕业生姓名、专业等信息。

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】格式相对统一,各专业都有相应的模板。通常包括以下部分:

校徽:象征着学校的荣誉和传承。

校名:学校英文全称

授予学位:本部分将注明获得的具体学位名称。

毕业生姓名:这是最重要的信息之一,标志着该证书是由特定人员获得的。

颁发日期:这是毕业正式生效的时间,也代表着毕业生学业的结束。

其他信息:根据不同的专业和学位,可能会有一些特定的信息或章节。

办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】价值很高,需要妥善保管。一般来说,应放置在安全、干燥、防潮的地方,避免长时间暴露在阳光下。如需使用,最好使用复印件而不是原件,以免丢失。

综上所述,办理(uoft毕业证书)加拿大多伦多大学毕业证【微信:741003700 】是证明身份和学历的高价值文件。外观简单庄重,格式统一,包括重要的个人信息和发布日期。对持有人来说,妥善保管是非常重要的。

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...

AI + Data Community Tour - Build the Next Generation of Apps with the Einstei...Paris Salesforce Developer Group

Build the Next Generation of Apps with the Einstein 1 Platform.

Rejoignez Philippe Ozil pour une session de workshops qui vous guidera à travers les détails de la plateforme Einstein 1, l'importance des données pour la création d'applications d'intelligence artificielle et les différents outils et technologies que Salesforce propose pour vous apporter tous les bénéfices de l'IA.Null Bangalore | Pentesters Approach to AWS IAM

#Abstract:

- Learn more about the real-world methods for auditing AWS IAM (Identity and Access Management) as a pentester. So let us proceed with a brief discussion of IAM as well as some typical misconfigurations and their potential exploits in order to reinforce the understanding of IAM security best practices.

- Gain actionable insights into AWS IAM policies and roles, using hands on approach.

#Prerequisites:

- Basic understanding of AWS services and architecture

- Familiarity with cloud security concepts

- Experience using the AWS Management Console or AWS CLI.

- For hands on lab create account on [killercoda.com](https://killercoda.com/cloudsecurity-scenario/)

# Scenario Covered:

- Basics of IAM in AWS

- Implementing IAM Policies with Least Privilege to Manage S3 Bucket

- Objective: Create an S3 bucket with least privilege IAM policy and validate access.

- Steps:

- Create S3 bucket.

- Attach least privilege policy to IAM user.

- Validate access.

- Exploiting IAM PassRole Misconfiguration