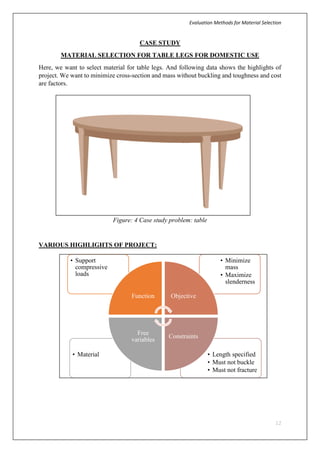

The document discusses evaluation methods for material selection, emphasizing the importance of choosing the right material for various applications based on numerous criteria such as functional and processability requirements, cost, and reliability. It outlines traditional approaches like cost versus performance methods and weighted property indices, and explores the implications of proper material selection on design, highlighting historical failures due to inadequate material properties. A case study on selecting materials for table legs is also included, illustrating practical application of the discussed methods.