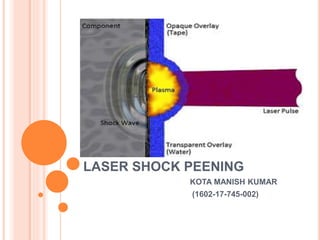

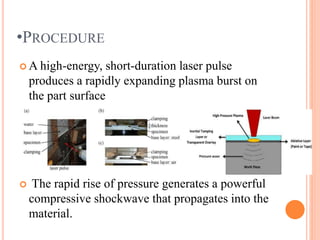

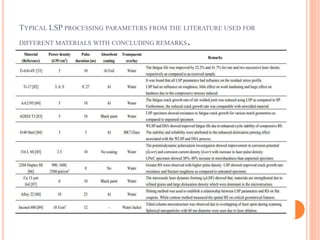

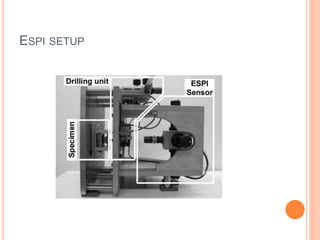

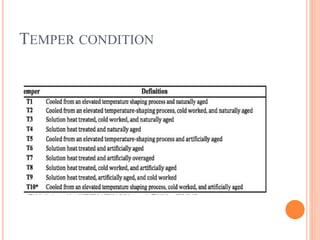

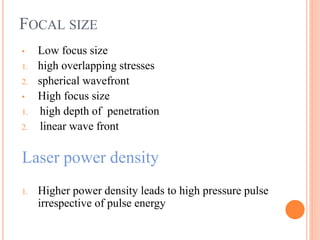

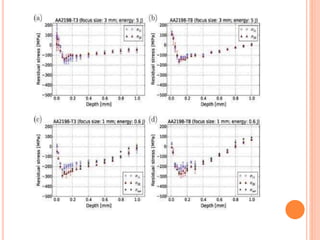

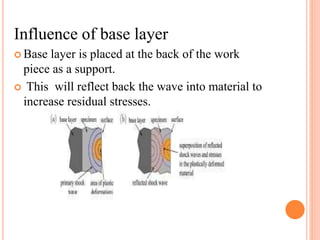

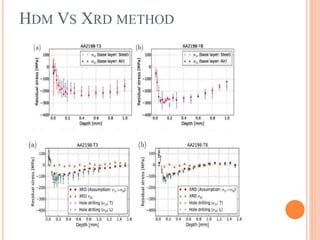

The document discusses laser shock peening (LSP) as a cold working process to enhance the material properties of metals, particularly focusing on residual stresses and benefits such as improved fatigue life. It includes experimental setups, methodologies for measuring residual stresses, and various factors influencing these stresses in different materials. The conclusion emphasizes that higher power density in LSP leads to increased compressive stresses and improved fatigue resistance in components.