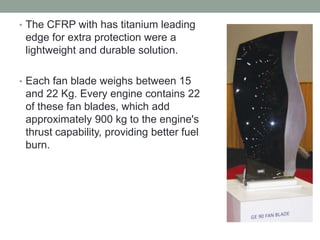

The document discusses material selection considerations for aircraft compressor blades. Key constraints include minimizing mass while withstanding high stresses, having high fracture toughness to tolerate impacts, and operating at temperatures up to 200°C. Titanium alloys currently provide the best balance of properties like strength and toughness relative to density, though carbon fiber reinforced polymers (CFRP) offer lower weight and are being developed. The selection process involves evaluating properties like strength and toughness relative to density for different materials to minimize weight while meeting requirements.