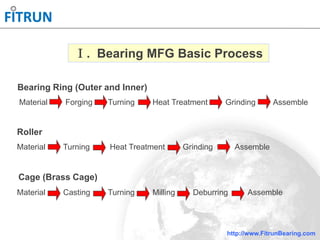

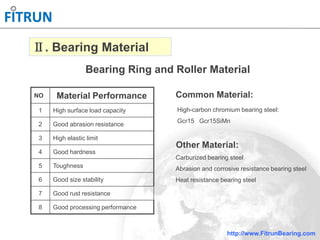

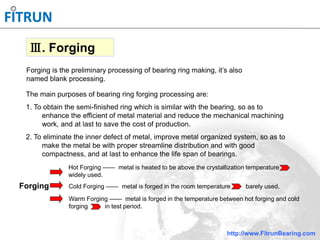

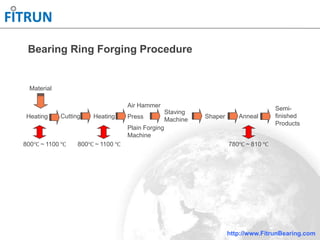

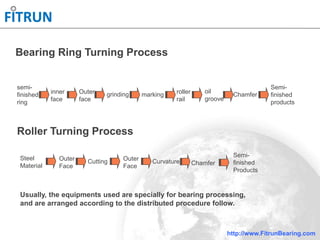

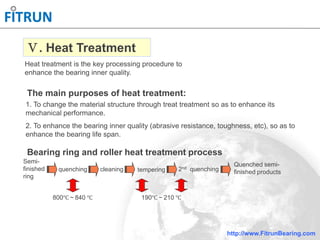

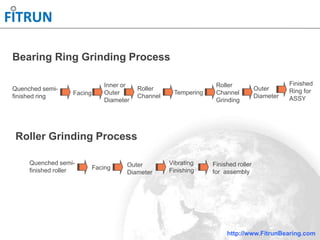

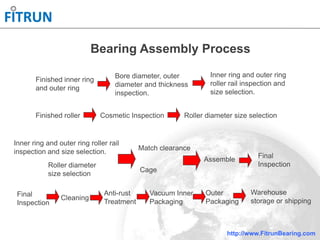

The document provides an overview of the basic manufacturing processes for ball bearings, including material selection, forging, turning, heat treatment, grinding, and assembly. It emphasizes the importance of precision in each stage to enhance the performance and lifespan of the bearings. Fitrun Bearing Co., Ltd. aims to produce high-quality ball bearings, including various types and sizes, while meeting customer expectations.