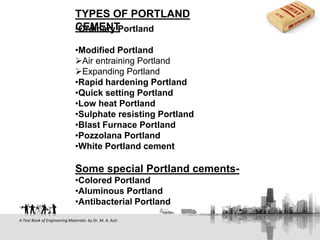

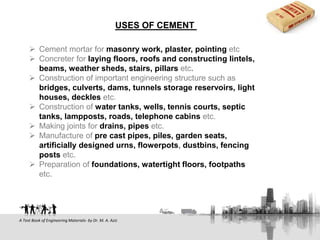

The document is a lecture on cement, detailing its composition, properties, classification, and manufacturing processes, including wet and dry methods. It highlights the various applications of cement in construction, such as in masonry, structural elements, and waterproofing. Additionally, it covers different types of Portland cement and special variants used for specific purposes.