Cement hydration is the chemical reaction between cement and water. When cement compounds are mixed with water, they dissolve and form a supersaturated solution. Hydrated compounds then precipitate out of the solution. The main hydrated compounds have low solubility and are responsible for the setting and hardening of cement. The quality, quantity, and rate of formation of these hydrated compounds affect the properties of the hardened cement.

![2

About Lechatelier mould:

It consists of a small split cylinder forming a mould having dimensions of internal dia

30mm and height 30mm. On either side of the split cylinder, two parallel indicating arms

with pointed ends of length 165mm is attached.

Remember, Lechatlier mould is a split cylinder (opened Cylinder)

Indicator arms determine the expansion of cement.

Procedure:

1. Before Performing the test, calculate the standard consistency of cement to

find out the water required to obtain the normal consistency(P).

2. Now add 0.78 times of water to the cement to give a paste of standard

consistency (0.78P).

3. Lightly apply oil to the Lechatelier mould and place it on a glass plate.

4. Now pour the cement paste into mould and close the mould using lightly oiled

glass plate and to avoid misplacement place a weight on it.

5. Then, submerge the whole assembly for 24Hrs in water bath at a temperature of

270

C

6. Remove the entire apparatus from water and then calculate the distance

separating two indicator points using measuring scale and note it as L1.

7. Again submerge the whole assembly in a water bath at a temperature of boiling

point for 3hours.

8. After completion of 3 hours remove the assembly from the bath and measure the

distance between two indicator points and note it as L2.

How do indicator arms determine expansion of cement?

Well, as mentioned above the mould is split cylinder which means that, if cement starts

expanding the length is increased by calculating the difference between the two lengths

the expansion of cement is found.

Expansion of Cement = L1-L2

A good cement (OPC, PPC, Rapid hardeneing etc) should have not more than below

expansion limits.

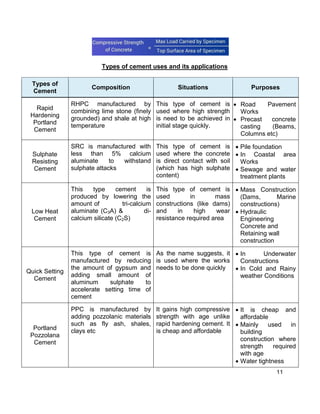

Types of Cement

Expansion

Limits

Ordinary Portland cement

[OPC]

33 Grade, 43 Grade, 53 grade

10mm

Portland Pozzolona Cement

[PPC]

10mm

Rapid Hardening cement 10mm

Low heat cement 10mm

Super sulphated cement 5mm](https://image.slidesharecdn.com/uniti-220528030050-3bb7c24d/85/Concrete-Technology-16-320.jpg)

![8

Test Result

The test result should be 5-7 mm measurement in Vicat apparatus.

Compressive Strength of Cement

Compressive strength is the capacity of material or structure to resist or withstand under

compression. The compressive strength of a material is determined by the ability of the

material to resist failure in the form of cracks and fissure.

In this test, the impact force applied on both faces of mortar specimen made with

cement and the maximum compression that cement specimen bears without failure

recorded.

In technical terms compressive strength of cement means,

The ability of cement specimen to resist the compressive stress when tested

under Compressive Testing Machine [CTM] at 28 days.

Apparatus:

The apparatus required for testing Compressive Strength of cement is

1. Compressive Test machine conforms to IS: 14858(2000)

2. Steel cubes of 7.06cm moulds (50cm2

face area) conforming to IS: 10080-1982,](https://image.slidesharecdn.com/uniti-220528030050-3bb7c24d/85/Concrete-Technology-22-320.jpg)