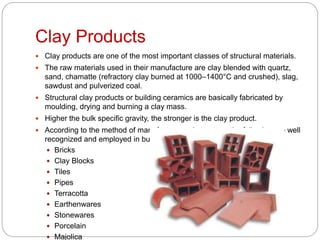

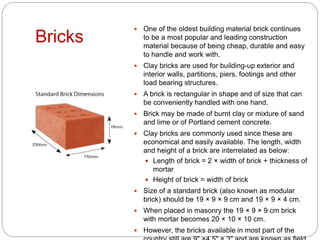

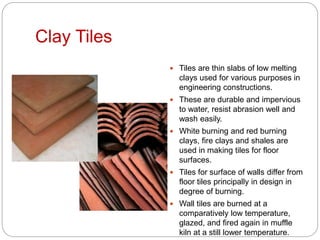

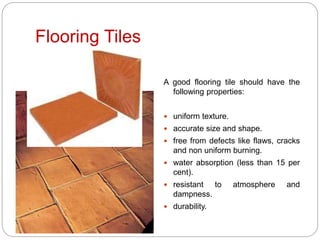

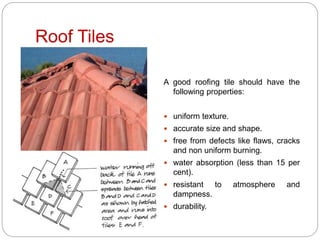

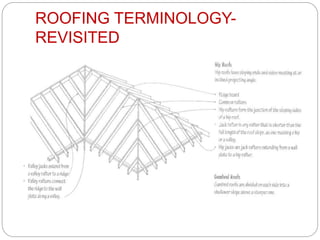

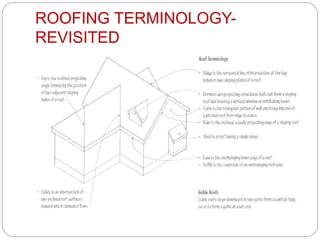

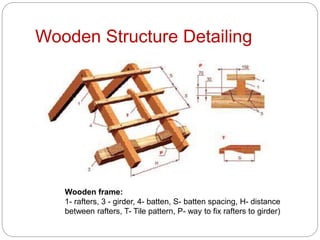

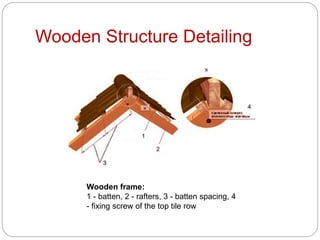

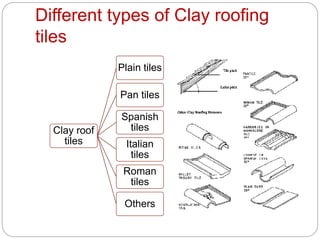

This document discusses various clay products used in construction, focusing on bricks, tiles, and roofing. It provides details on the manufacture and properties of bricks, tiles, and different types of clay roofing tiles. Bricks are made from clay or other materials and are used for walls, foundations etc. Tiles are thin clay slabs used for floors and walls, and are made through molding and firing. The document outlines the manufacturing process for tiles and desirable properties for flooring and roofing tiles. It also defines roofing terminology and provides diagrams of wooden roof structures and different types of clay roof tiles.