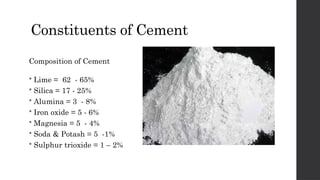

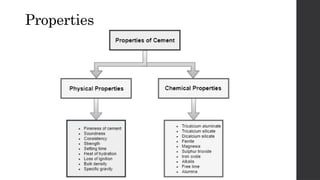

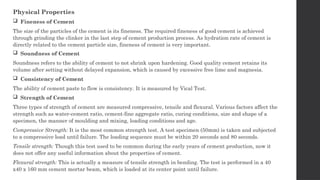

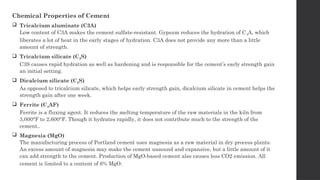

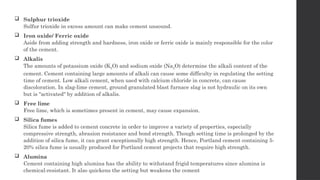

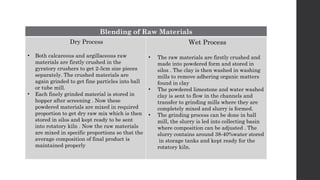

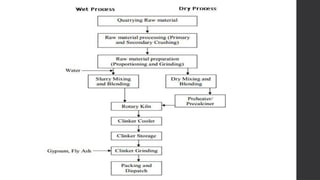

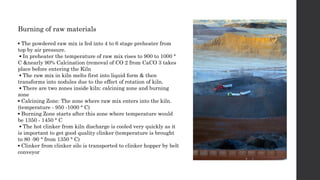

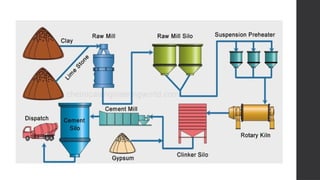

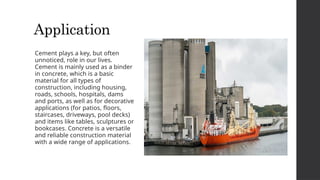

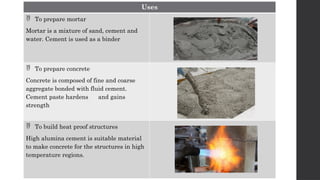

The document provides a comprehensive overview of cement, detailing its importance as a construction material, production processes, types, and properties. It highlights India's position as the second-largest cement producer and discusses the historical development of cement, various constituents, and types like Ordinary Portland Cement and Portland Pozzolana Cement. Additionally, it covers the physical and chemical properties of cement, manufacturing stages, and the roles of different materials used in cement production.