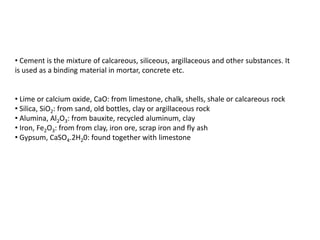

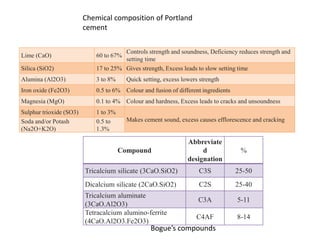

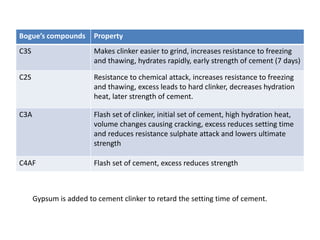

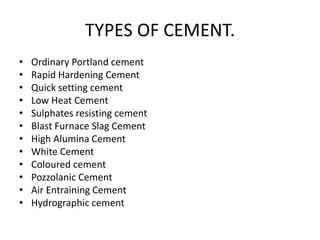

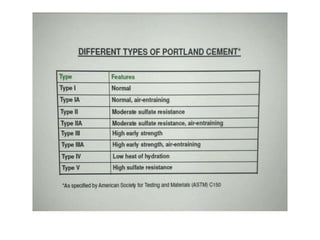

Joseph Aspedin introduced Portland cement in 1824 by mixing limestone and clay. There are various types of cement produced through different manufacturing processes and chemical compositions. Cement is made up of calcium compounds like calcium oxide and calcium silicates that set and bind aggregate materials when mixed with water. The most common type is ordinary Portland cement, used in general construction. Other types include rapid hardening cement, sulfate resisting cement, and low heat cement, each suited to specific conditions.